High-Quality UV Curing Ink Systems | Vtech Co., Ltd

Introducing Vtech Co., Ltd's UV Curing Ink Systems

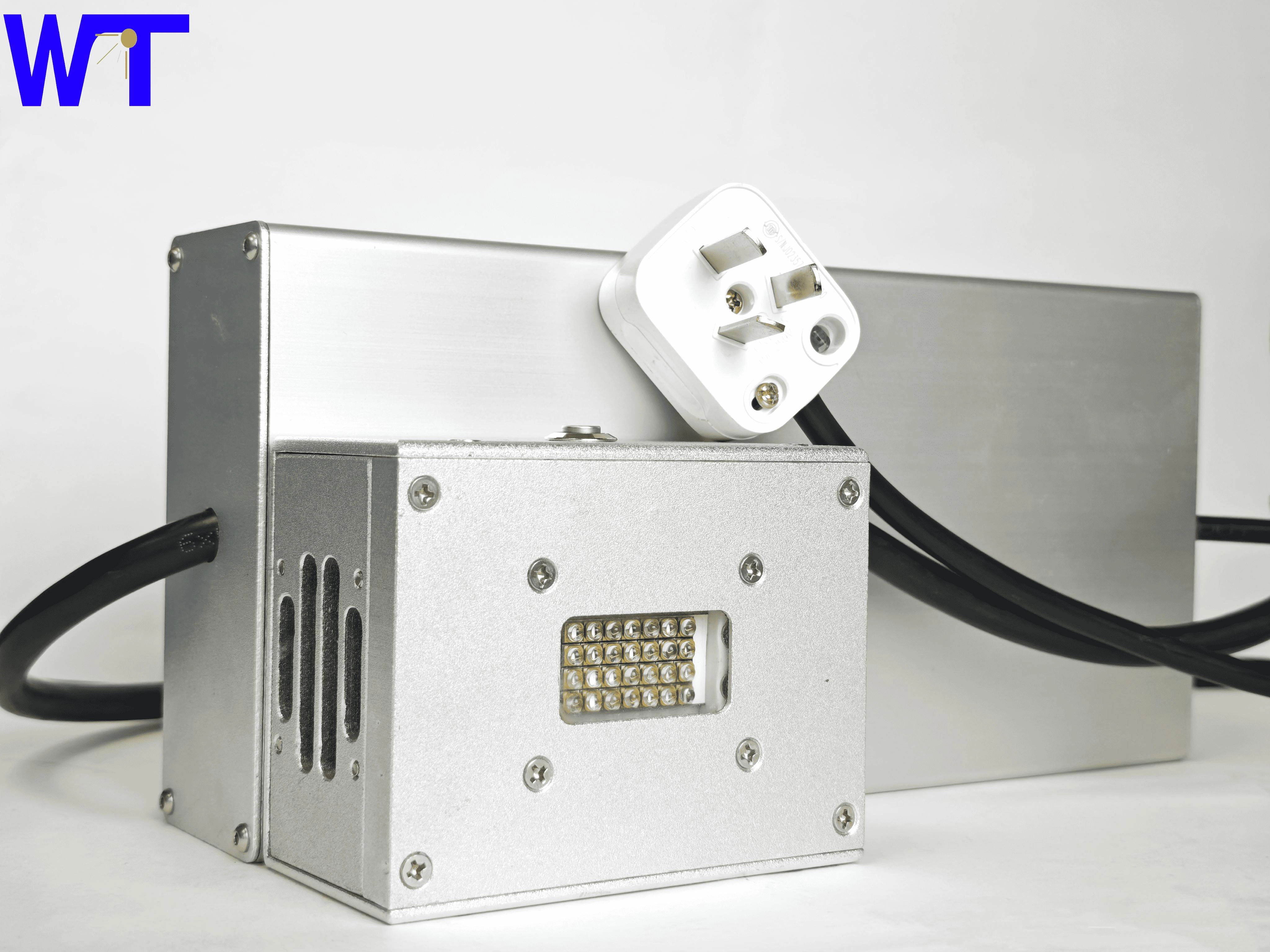

At Vtech Co., Ltd, we are proud to offer our high-quality UV curing ink systems for a wide range of printing applications. With our expertise and patented technology, we provide reliable and efficient UV and LED curing systems for offset press, gravure press, flexo press, coatings, silk screen print, and more. Our products are designed to optimize production and quality, making them an ideal choice for businesses looking to enhance their printing processes.

The Benefits of UV Curing Ink Systems

Our UV curing ink systems offer numerous benefits for businesses in the printing industry. With rapid curing times and low energy consumption, our systems can significantly improve production efficiency and reduce operational costs. Additionally, our UV curing ink is known for its excellent adhesion, scratch resistance, and durability, ensuring long-lasting and high-quality prints. By investing in Vtech Co., Ltd's UV curing ink systems, businesses can achieve superior printing results while minimizing environmental impact.

Versatile and Reliable Solutions for Various Presses and Printing Applications

Our UV curing ink systems are compatible with a wide range of printing presses, including offset, gravure, and flexo presses. Whether you are in the packaging, labeling, or commercial printing industry, our products are designed to meet the specific requirements of your printing applications. With Vtech Co., Ltd's expertise and customizable solutions, businesses can experience seamless integration and enhanced performance in their printing processes.

Exceptional Service and Expertise from a Leading Enterprise

With over a decade of experience, Vtech Co., Ltd has established itself as a leading enterprise in the UV curing systems industry. Our team of experts is dedicated to providing reliable service and technical support to ensure the seamless operation and maintenance of our UV curing ink systems. We understand the critical role that UV curing technology plays in the printing process, and we are committed to delivering solutions that meet the highest standards of quality and performance.

Innovation and Patented Technology Driving Industry Advancements

At Vtech Co., Ltd, we continuously invest in research and development to innovate and improve our UV and LED curing systems. Our commitment to technological advancement has resulted in numerous patents, allowing us to stay at the forefront of industry developments. By choosing Vtech Co., Ltd's UV curing ink systems, businesses can benefit from cutting-edge technology and unparalleled performance in their printing operations.

Conclusion:

When it comes to UV curing ink systems, Vtech Co., Ltd offers a comprehensive range of solutions designed to meet the diverse needs of the printing industry. With our expertise, patented technology, and commitment to innovation, we provide businesses with reliable, efficient, and high-quality UV and LED curing systems. Contact us today to explore how Vtech Co., Ltd's UV curing ink systems can optimize your printing processes and elevate the quality of your prints.

Can I use my own PLC and Electric cabinet?

how can we guarantee quality?

Can you do a design for me or company?

How to proceed an order for UV LED curing system?

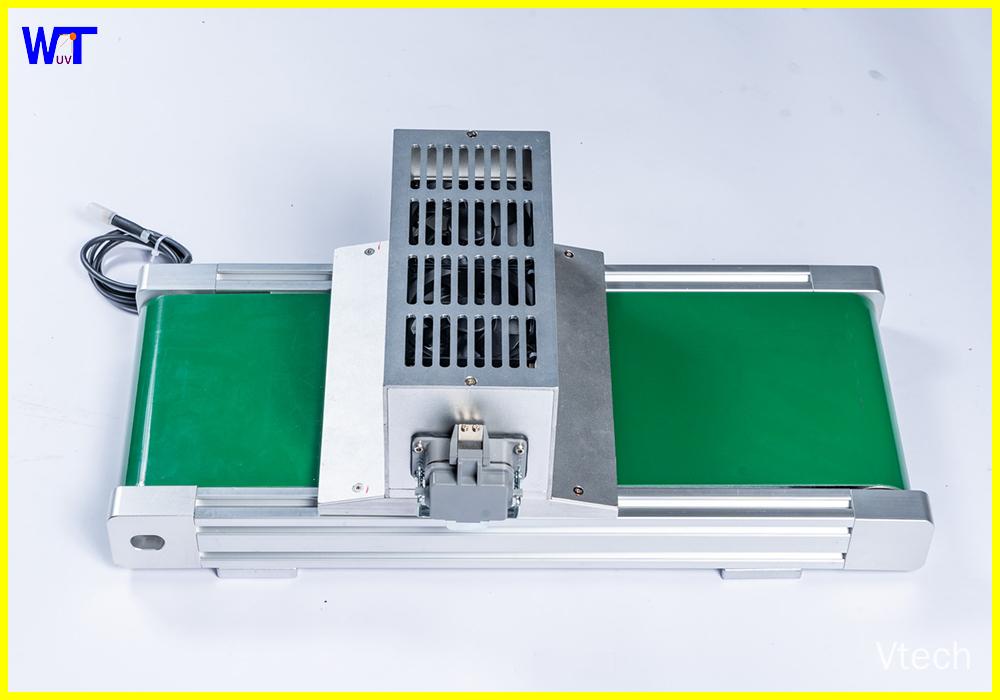

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipmentGuangzhou Weitai Electromechanical Invites You to 2025 Shenzhen International Film & Tape Expo to Explore Innovative Water-Cooled UV/LED System

As a professional manufacturer of water-cooled UV/LED systems, Guangzhou Weitai Electromechanical Co., Ltd. sincerely invites you to the 2025 Shenzhen International Film & Tape Expo (FILM & TAPE EXPO 2025). Our booth number is 12C136, and the exhibition will be held from October 28th to 30th, 2025 at the Shenzhen World Exhibition & Convention Center (Bao'an).

The core components and operation process of UV system (In offset printing press)

This article focuses on the operation mechanism of UV systems for offset printing machines. Starting with core values, it details the advantages of UV systems in rapid curing, multi-substrate compatibility, and print quality improvement. It then breaks down the five core components of the system (UV light source, reflector cover, cooling system, etc.) and their functions. Finally, it analyzes key operation links step by step, including ink supply, UV curing, cooling inspection, and post-maintenance. It provides clear technical references for printing industry practitioners and equipment operators, helping them understand how UV systems break through the limitations of traditional drying technologies and adapt to special printing needs such as packaging and labeling.

Showcasing at All Print Indonesia 2025: Water-Cooled UV Systems Empower Large-Scale Printing Equipment

From October 8 to 11, All Print Indonesia 2025—a key event for the printing industry—took place at JI Expo Jakarta. As a leading manufacturer of water-cooled UV systems tailored for large-scale equipment (offset printers, gravure printers, label printers), we showcased our core solutions, connecting with Southeast Asian printing professionals to explore efficiency and green transformation opportunities.

2025 Jakarta Printing Exhibition in Indonesia(All Print Indonesia)

The Jakarta Printing Exhibition in Indonesia is one of the influential professional exhibitions in the printing industry, held annually at the Jakarta Convention and Exhibition Center. The exhibition is dedicated to showcasing the latest achievements in printing technology, covering multiple fields such as digital printing, packaging printing, label printing, and 3D printing

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang