High-Quality UV Ink Curing Unit | Vtech Co., Ltd

Introducing Vtech Co., Ltd's UV Ink Curing Units

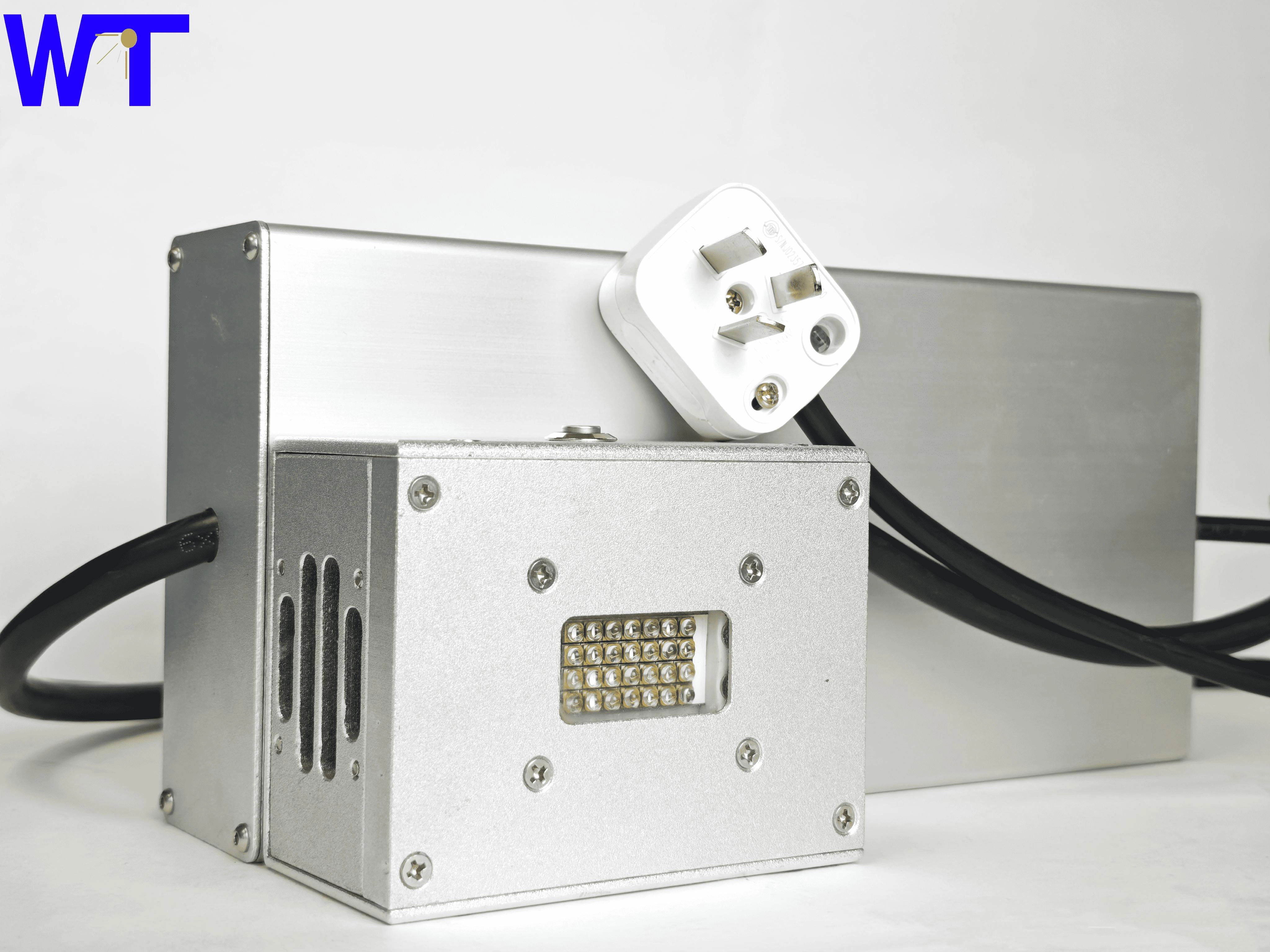

At Vtech Co., Ltd, we take pride in offering state-of-the-art UV ink curing units designed to meet the specific requirements of various printing processes. Our water-cooled UV curing systems and LED UV curing systems are highly efficient, reliable, and come with the assurance of superior quality. Whether you need a UV ink curing unit for offset press, gravure press, flexo press, coatings, silk screen print, or any other application, we have the perfect solution for you.

Features and Benefits of Our UV Ink Curing Units

Our UV ink curing units are engineered to deliver exceptional performance, ensuring fast and thorough curing of UV inks. With advanced technology and precise control mechanisms, our systems offer a range of benefits, including energy efficiency, reduced production time, improved print quality, and enhanced overall productivity. The versatility of our UV curing units makes them suitable for a wide range of applications, providing our clients with a competitive edge in the printing industry.

Reliable Service and Expertise You Can Trust

With our extensive experience and expertise in UV and LED curing systems, we are committed to providing reliable service and support to our clients. We have a wealth of knowledge in the field, allowing us to understand the unique needs and challenges of different printing processes. Our team is dedicated to offering comprehensive assistance, ensuring that you receive the most suitable UV ink curing unit for your specific requirements.

Customizable Solutions for Varied Printing Needs

At Vtech Co., Ltd, we understand that not all printing processes are the same, which is why we offer customizable solutions to cater to varied needs. Whether you require a UV ink curing unit for high-speed offset printing or intricate silk screen printing, we can tailor our systems to match your exact specifications. Our commitment to providing personalized solutions sets us apart, giving our clients the flexibility to optimize their production processes.

Leading the Way with Innovative Technology

As a pioneer in the development of water-cooled UV curing systems and LED UV curing systems, Vtech Co., Ltd has secured numerous patents in the industry. Our continuous research and development efforts have led to the creation of cutting-edge technologies that enhance the efficiency and performance of our UV ink curing units. By investing in our innovative solutions, you can stay ahead of the curve and achieve outstanding results in your printing operations.

Elevate Your Printing Process with Vtech Co., Ltd

When you choose Vtech Co., Ltd's UV ink curing units, you are making a strategic investment in the success of your printing business. Our commitment to delivering high-quality products, reliable service, and innovative solutions makes us the preferred choice for printers seeking to boost their capabilities and competitiveness. Join hands with us and experience the difference that our UV ink curing units can make in your production environment.

Conclusion

At Vtech Co., Ltd, we are dedicated to providing the printing industry with advanced UV ink curing units that deliver unparalleled performance and value. Our water-cooled UV curing systems and LED UV curing systems are designed to meet the diverse needs of modern printing processes, offering a perfect blend of efficiency, reliability, and innovation. Get in touch with us today to explore how our UV ink curing units can elevate your printing operations to new heights.

Remember, the customer wants to know how they will benefit from investing in our product, they want to know why they should choose us over the competition, and they want to see that we have the expertise and experience to deliver what we promise. Let's convey all of these messages effectively through our product descriptions, making sure to include relevant keywords like "UV ink curing unit" and "LED UV curing systems" for optimal search engine visibility and ranking.

lf the light intensity is adjustable?

How does your factory do the quality control?

Why and how do I replace a UV led?

Which wavelength do I need?

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipmentGuangzhou Weitai Electromechanical Invites You to 2025 Shenzhen International Film & Tape Expo to Explore Innovative Water-Cooled UV/LED System

As a professional manufacturer of water-cooled UV/LED systems, Guangzhou Weitai Electromechanical Co., Ltd. sincerely invites you to the 2025 Shenzhen International Film & Tape Expo (FILM & TAPE EXPO 2025). Our booth number is 12C136, and the exhibition will be held from October 28th to 30th, 2025 at the Shenzhen World Exhibition & Convention Center (Bao'an).

The core components and operation process of UV system (In offset printing press)

This article focuses on the operation mechanism of UV systems for offset printing machines. Starting with core values, it details the advantages of UV systems in rapid curing, multi-substrate compatibility, and print quality improvement. It then breaks down the five core components of the system (UV light source, reflector cover, cooling system, etc.) and their functions. Finally, it analyzes key operation links step by step, including ink supply, UV curing, cooling inspection, and post-maintenance. It provides clear technical references for printing industry practitioners and equipment operators, helping them understand how UV systems break through the limitations of traditional drying technologies and adapt to special printing needs such as packaging and labeling.

Showcasing at All Print Indonesia 2025: Water-Cooled UV Systems Empower Large-Scale Printing Equipment

From October 8 to 11, All Print Indonesia 2025—a key event for the printing industry—took place at JI Expo Jakarta. As a leading manufacturer of water-cooled UV systems tailored for large-scale equipment (offset printers, gravure printers, label printers), we showcased our core solutions, connecting with Southeast Asian printing professionals to explore efficiency and green transformation opportunities.

2025 Jakarta Printing Exhibition in Indonesia(All Print Indonesia)

The Jakarta Printing Exhibition in Indonesia is one of the influential professional exhibitions in the printing industry, held annually at the Jakarta Convention and Exhibition Center. The exhibition is dedicated to showcasing the latest achievements in printing technology, covering multiple fields such as digital printing, packaging printing, label printing, and 3D printing

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang