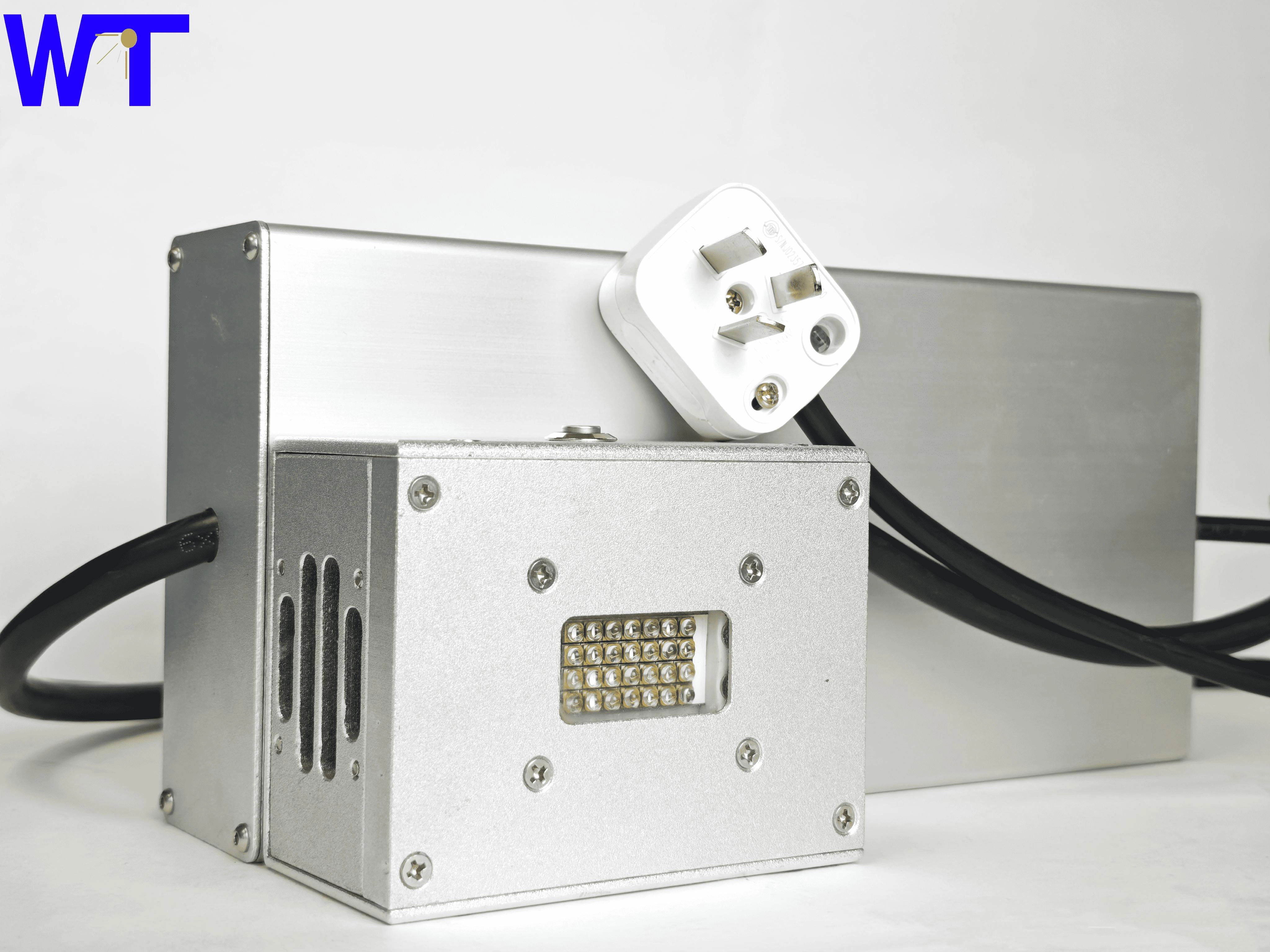

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

UV electronic transformer

It adopts European imported brands, comes with BUCK voltage stabilizing circuit, 10-100% stepless dimming, and has powerful operation protection, including over-current protection, over-heat protection, lamp disconnection protection, etc.

UV mercury lamp

American HANOVIA brand, the lamp is started with low voltage, which has little impact on the lamp startup, and the warranty is more than 1500 hours.

Electronic component

Using famous brands such as Japan's Mitsubishi, Switzerland's ABB, and the United States' VIE, the quality is guaranteed.

Fan

It adopts European crown fan, which has high pressure, large air volume, low noise and long life. The noise standard is below 85 decibels, which is in line with international standards.

Technical Parameters

Max. curing size

Max. electric power

Min. humidity

Blowing size

Warranty

2400mm

30KW

200mm

ф100mm

One year

Cooling mode

Nozzles type

Dichroic

Water pipe size

Water pipe joints

Water cooling/Air cooling

Quick plug

As chioce

ф14

Brass joints

UV LED Advantages

WT is a professional R&D and production of water cooled UV curing system, LED UV curing system enterprises.

WT has an array of UV lamp and LED products to meet almost any printing or converting need. All products can be integrated seamlessly by WT to fit your machine.

Print without limitations

Unlike UV lamps, LEDs emit little infrared heat towards the substrate. This avoids common issues such as high pile temperatures, curling of heat-sensitive materials and loss of moisture in paper.

Ultimate productivity and peace of mind

No moving parts for low maintenance and no warmup/cool-down mean less UV related downtime, which increases press productivity.

Reduced energy consumption

LED instant on-off means that no energy is consumed when the press is idle. The higher electrical efficiency of LEDs and the purity of UV output allow typical energy savings of over 70%, compared to H-UV or IR lamp systems.

No marking, no sealer or spray powder

UV LED inks and varnishes are 100% cured instantly after the LED lamp.

Circuit Diagram

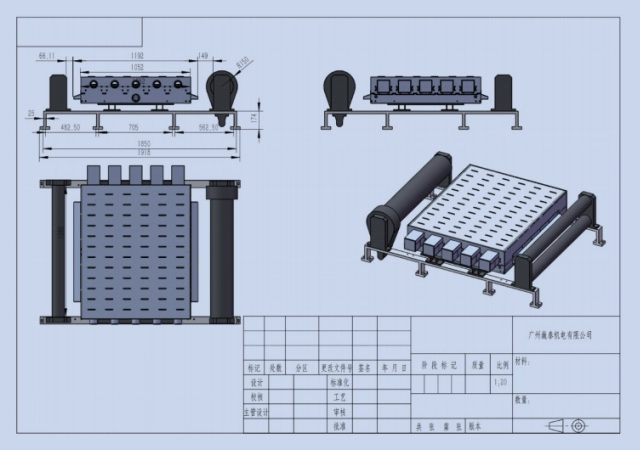

UV cassettes with water cooled nozzles

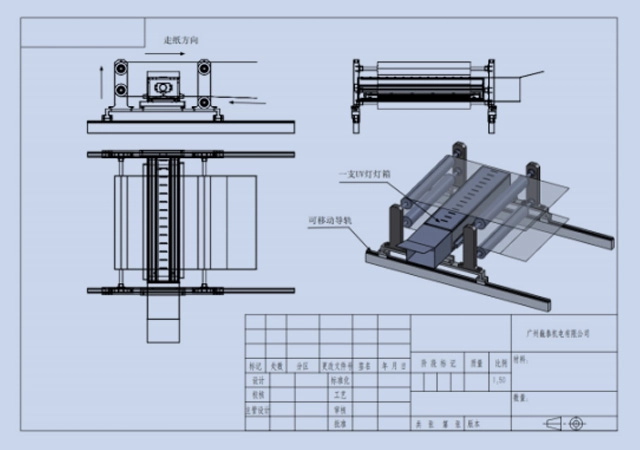

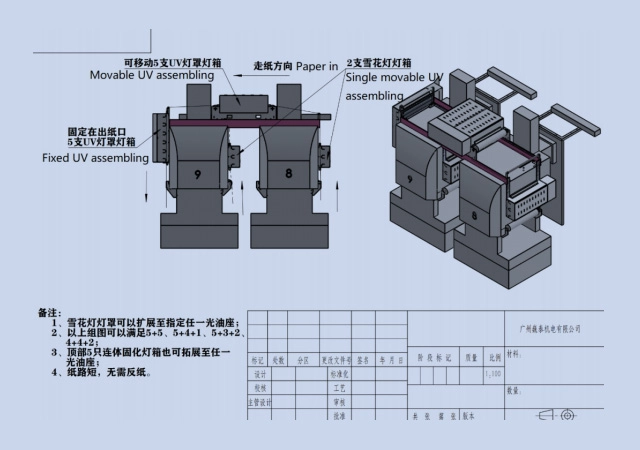

UV curing parameters for Roto gravure online system

UV exposur ing system parameters for Roto gravure online system

To achieve UV curing +UV drop off speed up to 180m/min.

Common Applications

Suitable for various printing machines such as offset printing, gravure printing, flexo printing, silk screen printing, etc.

UV print in sheetfed grevure press getting screen printing effects

UV print in sheetfed grevure press getting screen printing effects

Product Details: Air-cooled LED UV Curing System (Label Printer-Specific)

I. Technical Parameters

Most parameters are fully customizable to match your equipment and production needs:

Dimensions: Customizable (length × width × height, e.g., 200mm×50mm×40mm; adjust based on your label printer’s structure)

LED Wavelength: 365nm, 385nm, 395nm (optimized for your specific UV ink type)

Power: Customizable (e.g., 30W–300W, tailored to curing speed and ink thickness requirements)

Cooling Method: Forced air cooling (custom fan power/size available; optional dual-fan design for high-power models)

Operating Voltage: AC 110V/220V, DC 12V/24V, or custom (matches your label printer’s power system)

LED Lifespan: ≥20,000 hours (extended lifespan options available for heavy-duty use)

Curing Speed: Adjustable (≤0.3–1.5 seconds, optimized for your printing speed, e.g., up to 300m/min for high-speed rotary presses)

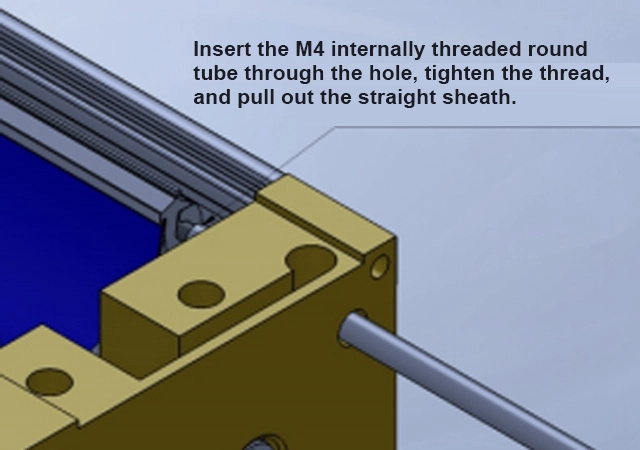

II. Structure & Components

Housing: Anodized aluminum alloy (standard); optional stainless steel for corrosive environments (custom thickness/finish available).

LED Array: High-density integrated LED chips (custom spacing/arrangement to ensure uniform light distribution across your label width).

Interfaces: Standardized air/electrical ports; custom interface designs available to match your label printer’s modular connections.

Mounting: Multi-position mounting holes (custom hole patterns/sizes available for seamless integration with your equipment’s layout).

III. Performance Advantages

Customized Efficiency: LED light intensity and curing speed are tailored to your production line, eliminating bottlenecks in high-speed or small-batch label printing.

Energy Savings: Up to 40% lower energy consumption than traditional mercury UV lamps (custom power tuning reduces waste for low-speed applications).

Stable Operation: Air-cooling system maintains working temperatures below 50°C (custom cooling upgrades available for high-power, 24/7 operation).

Material Compatibility: Cold LED light prevents heat damage to sensitive materials (e.g., thermal labels); customizable light intensity avoids over-curing thin films.

Eco-Friendly: Mercury-free, ozone-free, and RoHS/CE compliant (custom certifications available for regional market requirements).

Feel Free

To Contact us.

WT will be pleased to assist your evaluation and decision-making process to ensure that the optimal mercury arc, LED, or hybrid solution is matched to your application, process, and integration needs. Please contact our experienced team. We are available to offer guidance on product selection and can deliver the level of experienced system integration and ancillary components you require.

If you would like to find out more about this curing system, we are here to help. Please contact the sales representative that is best placed for your region.

Feel Free To Contact us.

WT will be pleased to assist your evaluation and decision-making process to ensure that the optimal mercury arc, LED, or hybrid solution is matched to your application, process, and integration needs. Please contact our experienced team. We are available to offer guidance on product selection and can deliver the level of experienced system integration and ancillary components you require.

If you would like to find out more about this curing system, we are here to help. Please contact the sales representative that is best placed for your region.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Offset LED pre-press testing machine

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang