WT UV Curing Technology: Superior & Reliable

Introducing WT UV Curing Technology: Superior Performance, Reliable Results

WT's UV curing technology represents a leap forward in efficiency and precision. Our advanced systems utilize the latest innovations in ultraviolet light to deliver unparalleled curing speed and exceptional durability. Whether you need to cure adhesives, coatings, inks, or composites, WT's solutions offer superior performance across diverse applications.

Our commitment to quality ensures consistent, reliable results. Rigorous testing and meticulous engineering guarantee the longevity and effectiveness of your cured materials. WT's UV curing technology minimizes downtime and maximizes productivity, making it a cost-effective and dependable choice for any industry. We pride ourselves on providing comprehensive support and technical expertise, helping you achieve optimal results and maximize your return on investment. Choose WT for a seamless and dependable UV curing solution built on innovation and reliability. Contact us today to learn more about how our technology can benefit your specific needs.

Advantages

UV energy uniformity ≥ 98%.

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

Can be designed and customized development, a variety of optical wavelength optional.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

Q&A

Can I use my own PLC and Electric cabinet?

lf the light intensity is adjustable?

how can we guarantee quality?

Are you a trader or manufacturer?

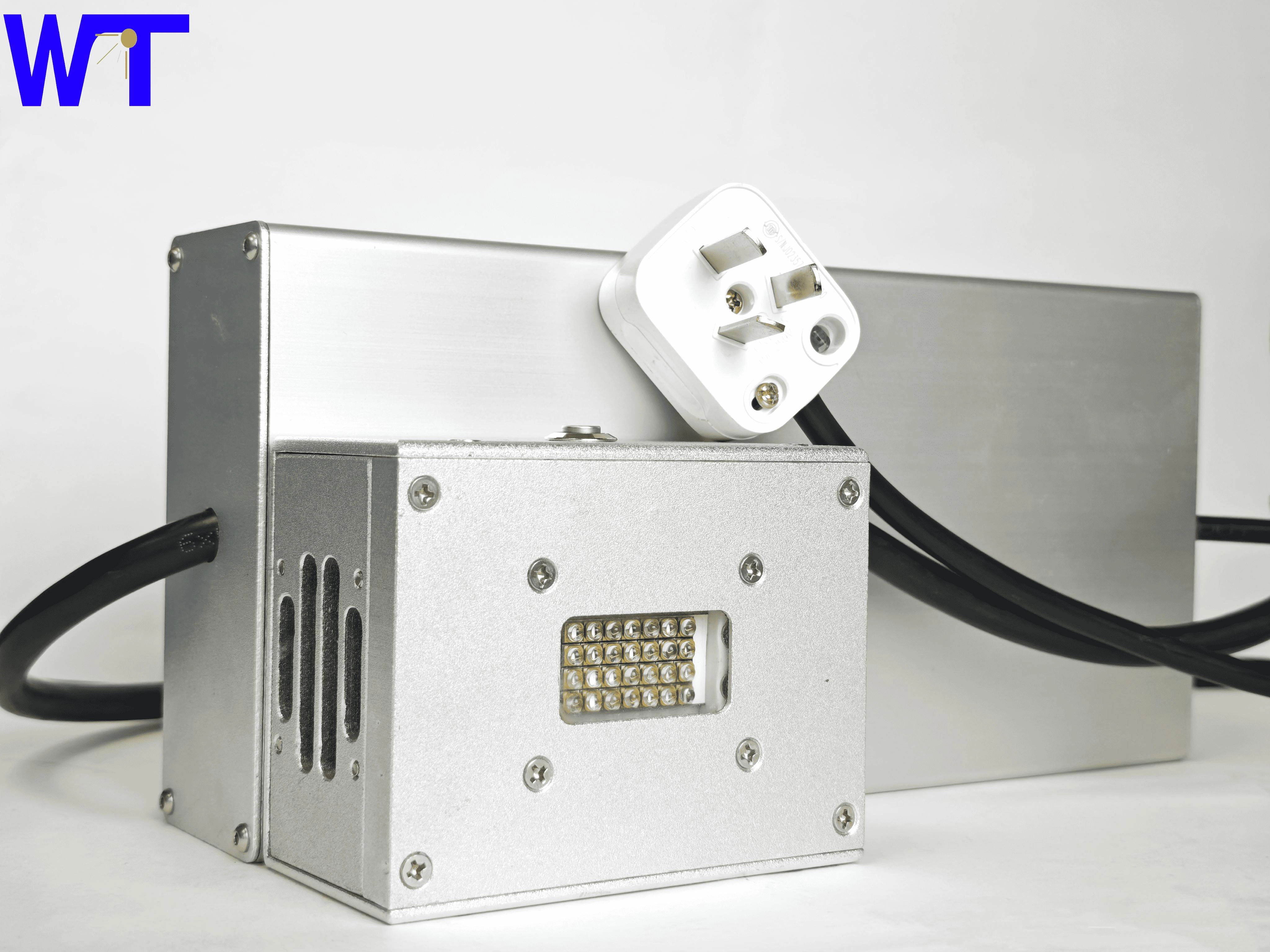

Small UV drying machine

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang