The Green Revolution in Manufacturing: VTECH How UV/LED Curing Systems Protect the Planet

Discover how WT is leading the charge in sustainable manufacturing with innovative UV and LED curing systems. Our cutting-edge technologies streamline processes while minimizing environmental impact. Embrace the green revolution with solutions designed to protect the planet and enhance efficiency. Learn how UV curing and LED curing systems are transforming industries and setting new standards for eco-friendly manufacturing.

I. The Environmental Cost of Conventional Curing Technologies

-

Mercury Lamp Hazards

Traditional mercury lamps contain toxic mercury, posing severe risks to soil and water ecosystems if improperly disposed of. Global ecological damage from mercury pollution exceeds billions of dollars annually. -

Energy Waste & Carbon Footprint

Thermal curing requires prolonged high-temperature heating, accounting for over 40% of production line energy use. Mercury lamps convert only 30% of energy into effective curing, wasting 70% as excess heat. -

VOCs: A Silent Threat

Solvent-based coatings release volatile organic compounds (VOCs) during curing, contributing to air pollution and workplace health hazards. -

II. UV/LED Curing: A Sustainable Breakthrough1. Energy Efficiency RedefinedLED curing achieves over 40% electro-optical efficiency—3x higher than mercury lamps (10-15%)—reducing energy consumption by 60-80%.Water-cooled UV systems optimize thermal management, minimizing energy waste and extending equipment lifespan.Case Study: A packaging manufacturer slashed annual energy costs by $15,000 per line using LED-UV, cutting 42 tons of CO₂ emissions.2. Zero-Pollution Material Solutions100% solid UV coatings eliminate solvents, eradicating VOC emissions and aligning with regulations like EU REACH and the U.S. Clean Air Act.Mercury-free LED lamps last 20,000+ hours, reducing hazardous waste by 90% compared to mercury alternatives.3. Building a Low-Carbon FutureInstant on/off functionality eliminates standby power drain, enabling integration with solar/wind energy for carbon-neutral operations.

-

III. The Eco-Advantage of Water-Cooled Technology

As a core innovation in UV/LED systems, water-cooled designs deliver added environmental value:

✅ Precision Temperature Control: Prevents material degradation and energy loss from overheating.

✅ Noise Reduction: Operates 20dB quieter than air-cooled systems, mitigating noise pollution.

✅ Water Conservation: Closed-loop cooling integrates with industrial water recycling, achieving 95% water reuse rates.

IV. Industry Outlook: From Compliance to Competitive Edge

With rising carbon tariffs (e.g., EU CBAM) and ESG-driven procurement policies, adopting green curing technologies is no longer optional—it’s a strategic advantage. Frost & Sullivan projects the UV/LED curing market to reach $7.8 billion by 2025, with 80% of buyers prioritizing carbon footprint certifications.

Innovating for a Cleaner Tomorrow

UV/LED curing systems exemplify how technology can drive both ecological stewardship and operational excellence. Through advancements like intelligent water-cooling and energy management, we empower manufacturers to achieve faster, cleaner, and future-proof production.

Guangzhou Weitai Electromechanical Invites You to 2025 Shenzhen International Film & Tape Expo to Explore Innovative Water-Cooled UV/LED System

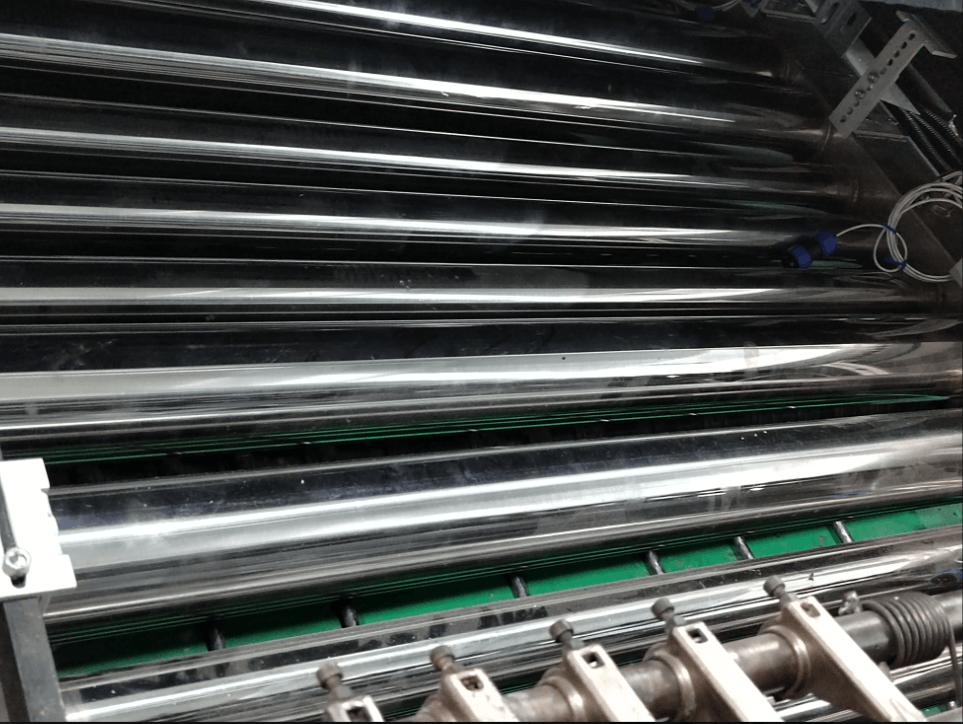

The core components and operation process of UV system (In offset printing press)

Showcasing at All Print Indonesia 2025: Water-Cooled UV Systems Empower Large-Scale Printing Equipment

2025 Jakarta Printing Exhibition in Indonesia(All Print Indonesia)

Vietnam Print Pack 2025 Concludes Successfully: Innovative Water-Cooled UV Systems Lead New Trends in Green Printing

Post exhibition report: Water cooled UV/LED system shines at RoSupack 2025, promoting green and sustainable printing

You may also like

Offset LED pre-press testing machine

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang