WT Products

Products Series

WT is a professional R&D and production of water cooled UV curing system, LED UV curing system enterprises.

WT has an array of UV lamp and LED products to meet almost any printing or converting need. All products can be integrated seamlessly by WT to fit your machine.

WT Products

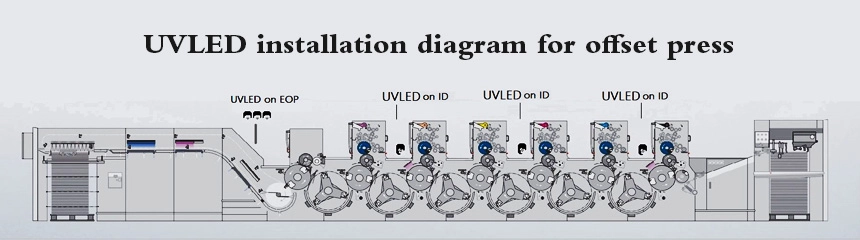

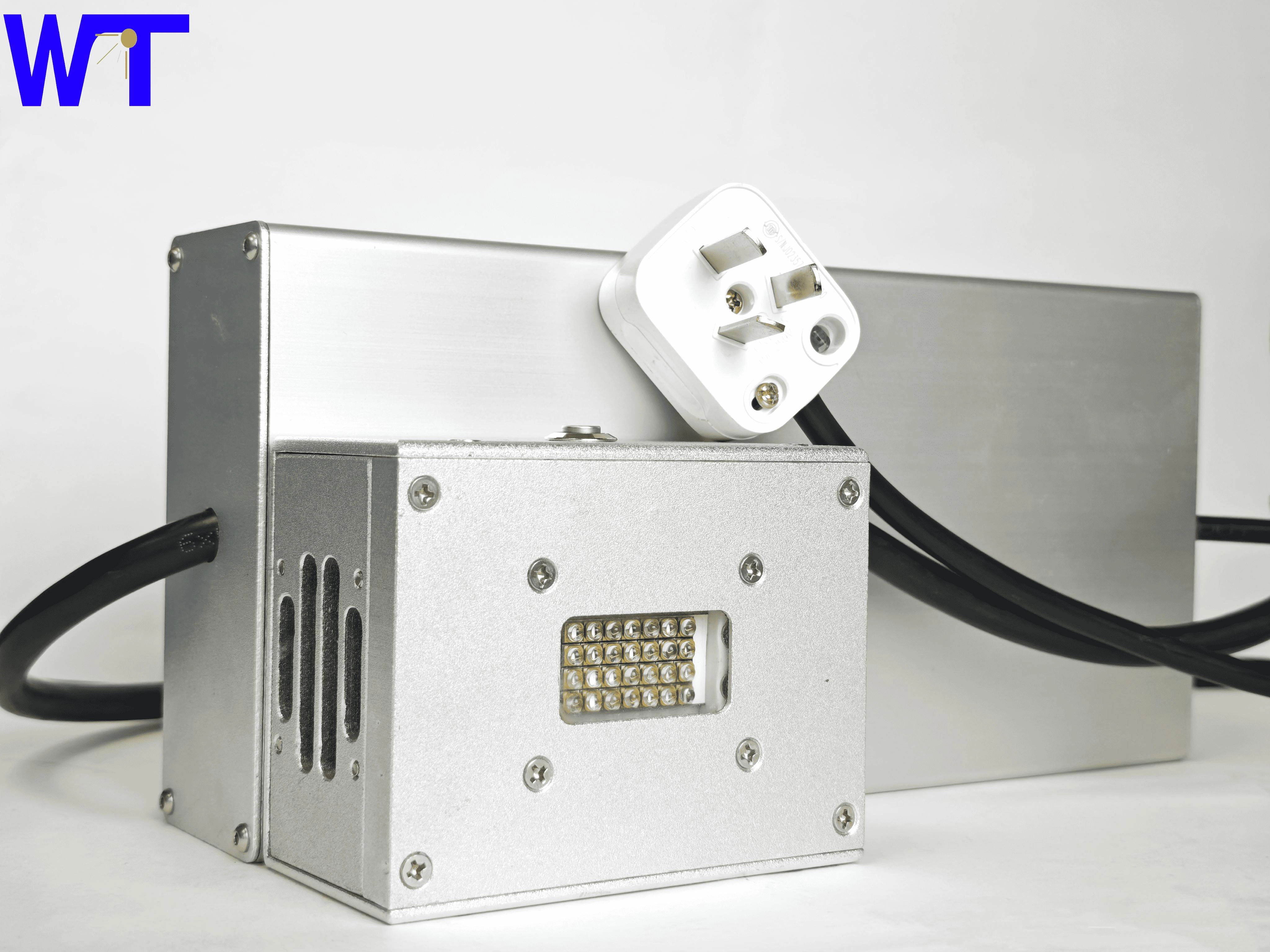

UV LED Systems

Curable traditional UV ink, dedicated for offset printing machines.

UV offset ink / UV gravure ink / UV flexo ink

UVLED system is a single wavelength light source in ultraviolet curing, generally using 365nm-405nm wavelength UV light to cure ink layer.

WT's LED water cooling system uses a plane lens, no curved surface refraction, no loss of light intensity, one time of concentrating to parallel distribution of focus points, no secondary refraction into a line, which increases the light intensity by more than 30%, no color difference between the ink layers after curing, the paper temperature is kept at room temperature, and the curing is thorough for Uv inks.

Efficient Curing: UV LED Systems utilize high-intensity UV light sources to instantly cure printing inks, enhancing production efficiency.

Energy saving and environmental protection: Compared to traditional mercury lamps, UV LED systems are more energy-efficient and do not require heating or cooling time, reducing energy waste.

Low Heat Radiation: UV LED systems produce minimal heat radiation, making them suitable for temperature-sensitive printing materials and reducing thermal stress.

WT Products

Traditional UV Curing System

Tradition UV Systems pioneering the UV Water-cooled technology in the industry, we provide efficient and reliable UV curing solutions for the printing process. Our UV systems have outstanding applications in various fields such as offset press, label printing, gravure press, and flexo, offering diversified choices to our customers.

Additionally, UV Lamp Systems are used for rapidly curing coatings, paints, and adhesives, thereby increasing production efficiency.

Due to their efficiency, environmental friendliness, and energy-saving advantages, UV Lamp Systems find wide applications in food processing, healthcare, industrial production, and more.

WT Products

UV Water-cooled Lampshade

UV Water-cooled Lampshade is an efficient cooling device designed for ultraviolet (UV) lamps, commonly used in industrial and laboratory applications. It employs advanced water-cooling technology to effectively reduce the temperature of UV lamps, extending their lifespan and enhancing performance.

UV Water-cooled Lampshades not only ensure the stability of UV lamps during high-intensity operation but also help minimize the heat impact on the surrounding environment. These devices are typically easy to install and maintain, making them suitable for various applications that require reliable UV irradiation.

Mechanical Parameters:

WT Products

WT UVLED Advantages

UVLED is an advanced ultraviolet light curing technology widely used in printing, coating, and curing applications. The working principle of UVLED involves generating ultraviolet light through Light Emitting Diodes (LEDs), enabling the instant curing of coatings or inks. Compared to traditional UV light sources, UVLED offers numerous advantages.

1. Intelligent.

2. Get rid of powder spray and film laminated.

3. Saving your preparation time.

4. Realize artcrafts on paper surface by UV inks such as UV coating, cast & cure etc.

WT Products

Film Printing

PP、OPP、PE Flexo UV Printing and Curing.

Film Printing is a traditional printing process that involves applying ink or pigments onto special films and then transferring the image onto various types of materials such as paper, plastic, or textiles.

Film Printing is commonly used for producing high-quality printed materials like brochures, posters, packaging, and labels. It is known for its ability to capture fine image details, vibrant color saturation, and long-term durability, making it still popular in some specialized applications.

1. Film Printing achieves high-resolution printing, ensuring clear and detailed patterns and text.

-

2. The technology is suitable for various types of film materials, including polyester film, polyethylene film, etc., making it widely applicable across different industries.

-

3. Products printed with Film Printing exhibit strong durability, resisting friction and wear, making it suitable for products that require longevity.

-

4. Film Printing supports personalized design and customization, making products visually appealing and meeting diverse market demands.

-

5. Film Printing can also choose environmentally friendly materials and printing processes, aligning with modern societal demands for sustainability.

WT Products

Automatic UV spot varnishing machine

Max.Sheet size:730L*1040Wmm

Min.sheet size:310L*406mm

Coating Thickness:0.15mm-0.60mm

Max coating speed:6500-8000sheets

Water base:Up to 7000

UV varnishing:Up to 7500

Spot UV:Up to 4500

100gsm thin paper:Up to 4000

Blister:Up to 5000

Soft touch:Up to 4000

Oil replace plastic:Up to 6000

Total Power:60kw

Dimension(L W H):9800*2260*2100mm

Weight:7800KG

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Offset LED pre-press testing machine

Water-cooled LED curing equipment

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Feel Free To Contact us.

WT will be pleased to assist your evaluation and decision-making process to ensure that the optimal mercury arc, LED, or hybrid solution is matched to your application, process, and integration needs.

Please contact our experienced team. We are available to offer guidance on product selection and can deliver the level of experienced system integration and ancillary components you require.

If you would like to find out more about this curing system, we are here to help. Please contact the sales representative that is best placed for your region.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang