Vtech Exhibits Cutting-Edge UV Curing Technology at The 21st International Plastic, Printing and Packaging Industry Exhibition

The exhibition also offered valuable opportunities to explore future collaborations, helping Vtech further solidify its position as a leader in UV curing technology for the printing and packaging industries.

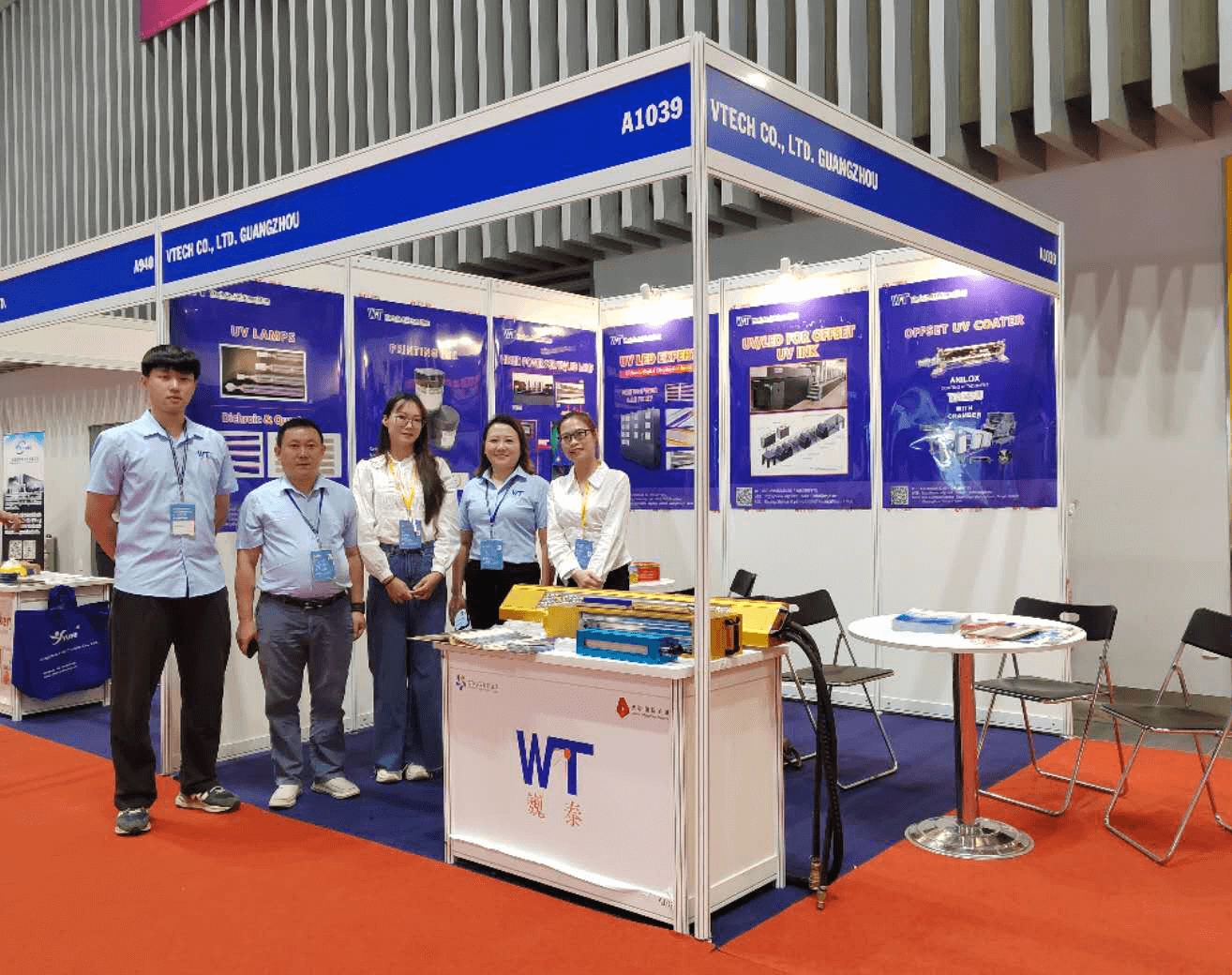

Vtech Co., Ltd. Guangzhou participated in the 21st International Plastic, Printing, and Packaging Industry Exhibition, held in 2024. This prestigious event, known for gathering industry leaders and innovators, provided Vtech with the perfect platform to showcase its advanced UV curing technologies to a global audience. The exhibition attracted professionals from the plastics, printing, and packaging industries, creating an excellent opportunity for Vtech to highlight its water-cooled UV curing systems and LED UV curing solutions.

Innovative UV Curing Solutions for a Sustainable Future

As a leader in UV curing technology, Vtech has been at the forefront of developing energy-efficient, high-performance systems for the printing and packaging industries. At this year’s exhibition, Vtech presented its water-cooled UV curing systems and LED UV curing systems, which are known for their ability to enhance operational efficiency and deliver superior curing results while minimizing energy consumption.

Vtech’s water-cooled UV curing systems are designed to handle high volumes of printing while maintaining consistent temperature control, preventing overheating, and ensuring stable operation even under demanding conditions. In addition, the LED UV curing systems offer significant environmental benefits, with lower energy consumption and longer operational lifespans, reducing the carbon footprint of production processes.

Interactive Demos and Networking Opportunities

During the exhibition, Vtech’s booth attracted a large number of visitors, including business professionals, industry experts, and potential partners. Attendees had the opportunity to interact with Vtech’s knowledgeable staff, who conducted live demonstrations of the company’s UV curing systems. These demonstrations highlighted the precision and quality of Vtech’s solutions, showcasing their versatility in various applications such as offset press, gravure press, flexo press, and coating.

The exhibition also provided an excellent networking opportunity, allowing Vtech to engage with key stakeholders in the plastics, printing, and packaging industries. The event fostered discussions about future industry trends, potential collaborations, and the importance of sustainable, high-quality curing technology for meeting the growing demands of these sectors.

Looking Toward the Future

As a company committed to innovation and sustainability, Vtech is dedicated to advancing UV curing technology and providing solutions that support the evolving needs of the printing and packaging industries. The 21st International Plastic, Printing, and Packaging Industry Exhibition has provided valuable insights into the future of UV curing technology and the industry at large.

Summary:

At the 21st International Plastic, Printing, and Packaging Industry Exhibition, Vtech showcased its advanced UV curing systems, including its water-cooled and LED UV curing technologies. The event allowed Vtech to demonstrate the efficiency, quality, and sustainability of its products while engaging with key industry professionals. The exhibition also offered valuable opportunities to explore future collaborations, helping Vtech further solidify its position as a leader in UV curing technology for the printing and packaging industries.

FAQs

-

What is the 21st International Plastic, Printing, and Packaging Industry Exhibition?

The 21st International Plastic, Printing, and Packaging Industry Exhibition is a global event that brings together key players in the plastics, printing, and packaging industries to showcase innovations, products, and technologies. It serves as a platform for networking, learning, and exploring new business opportunities. -

What products did Vtech showcase at this exhibition?

Vtech showcased its water-cooled UV curing systems and LED UV curing systems, both of which are designed to improve efficiency, sustainability, and product quality in the printing and packaging industries. -

What are the advantages of Vtech’s water-cooled UV curing system?

Vtech’s water-cooled UV curing systems provide superior temperature management, making them ideal for long printing runs. This ensures consistent curing results while preventing overheating, even in high-demand production environments. -

How does Vtech’s LED UV curing system contribute to sustainability?

Vtech’s LED UV curing systems consume less energy and generate less heat, which not only reduces operational costs but also minimizes the environmental impact of the production process. The longer lifespan of LED systems further contributes to sustainability by reducing the need for frequent replacements. -

How can I learn more about Vtech’s products and solutions?

To learn more about Vtech’s UV curing systems and other technologies, you can visit their official website, contact their sales team, or request a demo to see their products in action. Vtech is also available for consultations and partnerships to discuss tailored solutions for your business needs.

Guangzhou Weitai Electromechanical Invites You to 2025 Shenzhen International Film & Tape Expo to Explore Innovative Water-Cooled UV/LED System

The core components and operation process of UV system (In offset printing press)

Showcasing at All Print Indonesia 2025: Water-Cooled UV Systems Empower Large-Scale Printing Equipment

2025 Jakarta Printing Exhibition in Indonesia(All Print Indonesia)

Vietnam Print Pack 2025 Concludes Successfully: Innovative Water-Cooled UV Systems Lead New Trends in Green Printing

Post exhibition report: Water cooled UV/LED system shines at RoSupack 2025, promoting green and sustainable printing

You may also like

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang