High-Quality Multi Pole LED UV Curing System | Vtech Co., Ltd

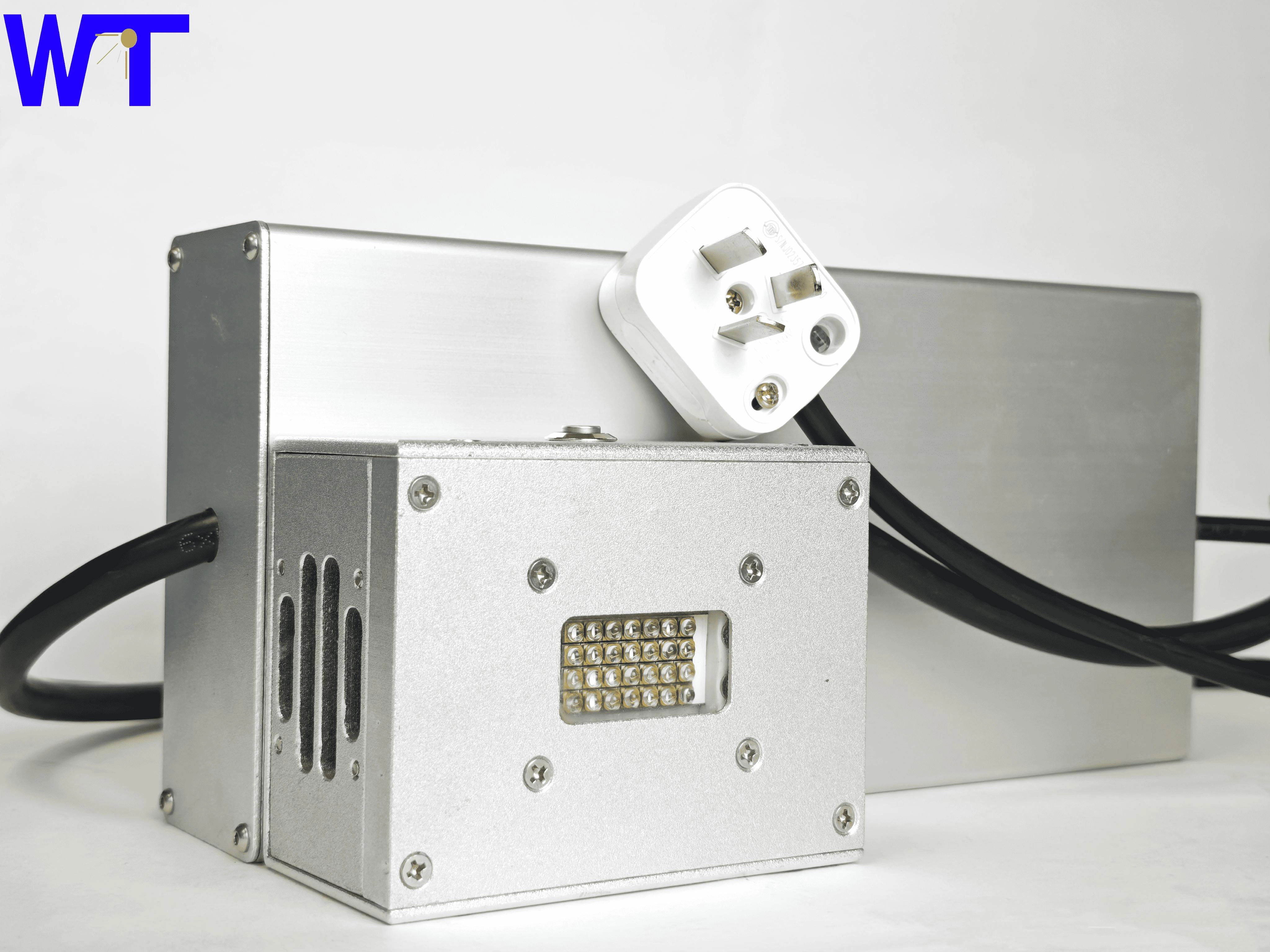

Discover the innovative and high-performance multi pole LED UV curing system offered by Vtech Co., Ltd. With our years of experience and expertise in the industry, we have developed advanced curing systems that are ideal for various printing and coating applications.

Advanced Technology:

Our multi pole LED UV curing system features cutting-edge technology that ensures efficient and consistent curing of inks, coatings, and adhesives. The water-cooled design enhances the system's durability and long-term performance, making it a reliable choice for demanding production environments.

Versatile Applications:

Whether you are in the offset press, gravure press, flexo press, or silk screen printing industry, our LED UV curing system is designed to meet your specific needs. The versatile capabilities of our system make it suitable for a wide range of printing and coating applications, providing excellent curing results every time.

Patented Designs:

At Vtech Co., Ltd, we take pride in our patented designs that set our LED UV curing system apart from the competition. Our dedication to research and development has resulted in unique and innovative features that enhance the performance and reliability of our curing systems.

Efficient Production:

By adopting our multi pole LED UV curing system, you can experience efficient and cost-effective production processes. The advanced curing technology ensures rapid curing times, leading to increased productivity and reduced production time, ultimately contributing to higher profitability for your business.

Reliable Service:

As a trusted provider of UV curing systems, Vtech Co., Ltd offers reliable service and support to ensure the optimal performance of our products. Our team of experts is committed to assisting you in finding the right solution for your specific application needs, providing peace of mind and confidence in your production processes.

Conclusion:

Embrace the future of curing technology with Vtech Co., Ltd's multi pole LED UV curing system. With our commitment to innovation and quality, you can elevate your production capabilities and achieve outstanding curing results in your printing and coating processes. Choose Vtech Co., Ltd for reliable performance and efficient production.

What's the whole UV LED curing system including?

How to proceed an order for UV LED curing system?

Why choose Vtech's UV LED curing machine?

Which wavelength do I need?

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipmentWhy Does Varnish Turn Yellow? Professional Anti-Yellowing Solutions for Printing & Coating Industries

This article details the 4 core causes of varnish yellowing and provides a full-process anti-yellowing plan covering material selection, process optimization, and storage protection.

Comprehensive Guide to UV Lamp Fusing and Bending Issues: Causes, Solutions & Prevention

This article focuses on two common faults of UV lamps: fusing and bending. It briefly analyzes their causes and provides emergency treatment, repair points and long-term prevention measures, offering practical references for UV lamp use and maintenance.

Guangzhou Weitai Electromechanical Invites You to 2025 Shenzhen International Film & Tape Expo to Explore Innovative Water-Cooled UV/LED System

As a professional manufacturer of water-cooled UV/LED systems, Guangzhou Weitai Electromechanical Co., Ltd. sincerely invites you to the 2025 Shenzhen International Film & Tape Expo (FILM & TAPE EXPO 2025). Our booth number is 12C136, and the exhibition will be held from October 28th to 30th, 2025 at the Shenzhen World Exhibition & Convention Center (Bao'an).

The core components and operation process of UV system (In offset printing press)

This article focuses on the operation mechanism of UV systems for offset printing machines. Starting with core values, it details the advantages of UV systems in rapid curing, multi-substrate compatibility, and print quality improvement. It then breaks down the five core components of the system (UV light source, reflector cover, cooling system, etc.) and their functions. Finally, it analyzes key operation links step by step, including ink supply, UV curing, cooling inspection, and post-maintenance. It provides clear technical references for printing industry practitioners and equipment operators, helping them understand how UV systems break through the limitations of traditional drying technologies and adapt to special printing needs such as packaging and labeling.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang