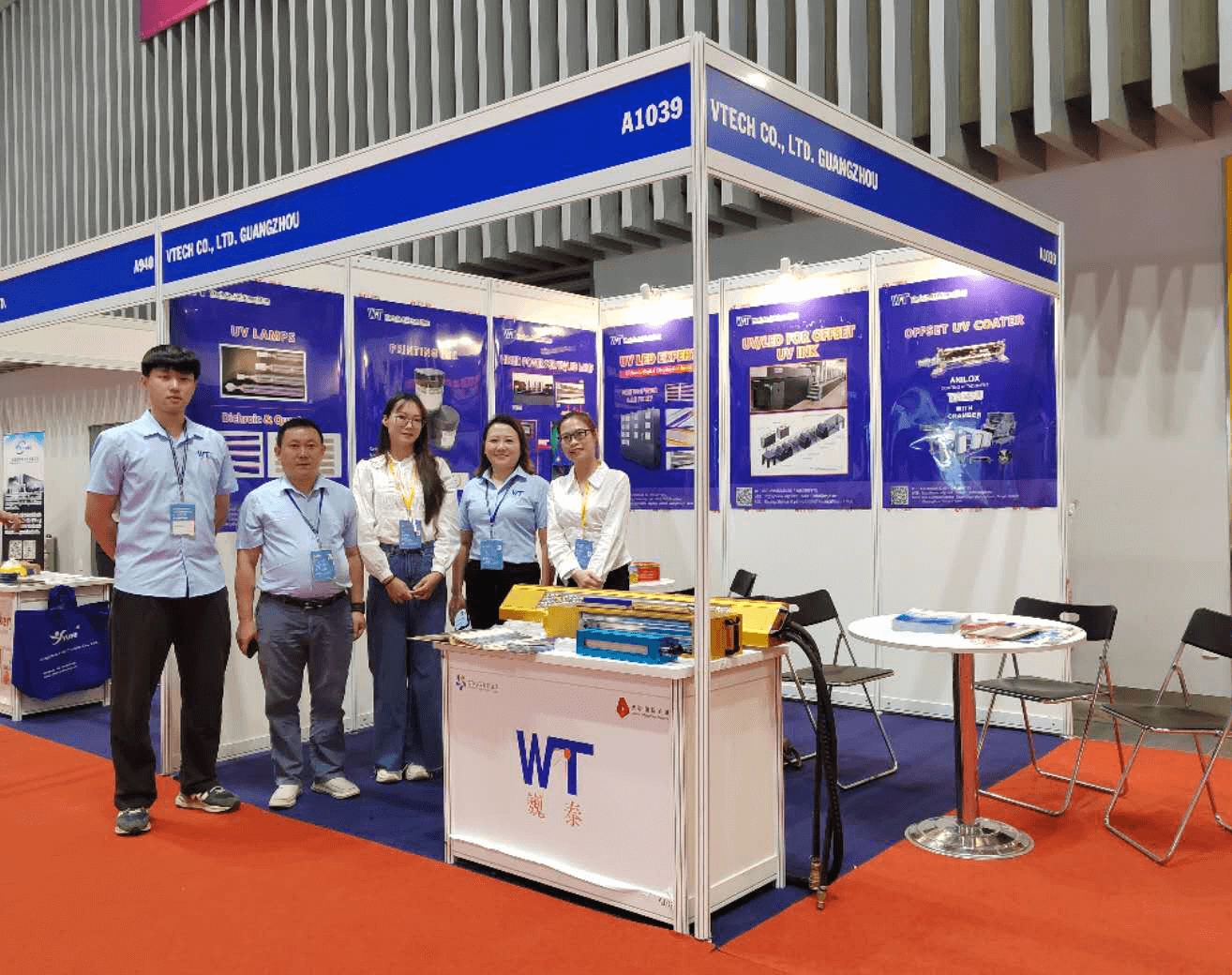

Vtech Shines at Drupa 2024, Showcasing Industry-Leading UV Curing Technology

The event not only attracted a significant number of industry professionals to Vtech’s booth but also opened up new opportunities for collaboration. Vtech's presence at Drupa 2024 reaffirmed its position as a leading provider of UV curing solutions, poised to meet the evolving needs of the global printing and packaging sectors.

At the 2024 Drupa International Printing Exhibition, Vtech Co., Ltd. Guangzhou showcased its latest advancements in UV curing technology, attracting significant attention from the global printing and packaging industries. As one of the most influential events in the printing industry worldwide, Drupa brings together cutting-edge technology and solutions. Vtech used this opportunity to engage deeply with clients and partners from around the world, demonstrating its technological strength and innovation in the UV curing field.

Innovative Technology Leading Industry Trends

Since its founding in 2006, Vtech has focused on the research, development, and production of UV curing systems, striving to provide customers with efficient and stable curing solutions. At this year’s exhibition, Vtech highlighted its water-cooled UV curing systems and LED UV curing systems, both of which excel in energy efficiency, precise curing, and durability. These systems are designed to meet the printing industry’s demands for high quality and efficiency.

Highlighted Products at the Exhibition

At Drupa 2024, Vtech showcased several flagship products that attracted numerous visitors:

-

Water-Cooled UV Curing Systems:

-

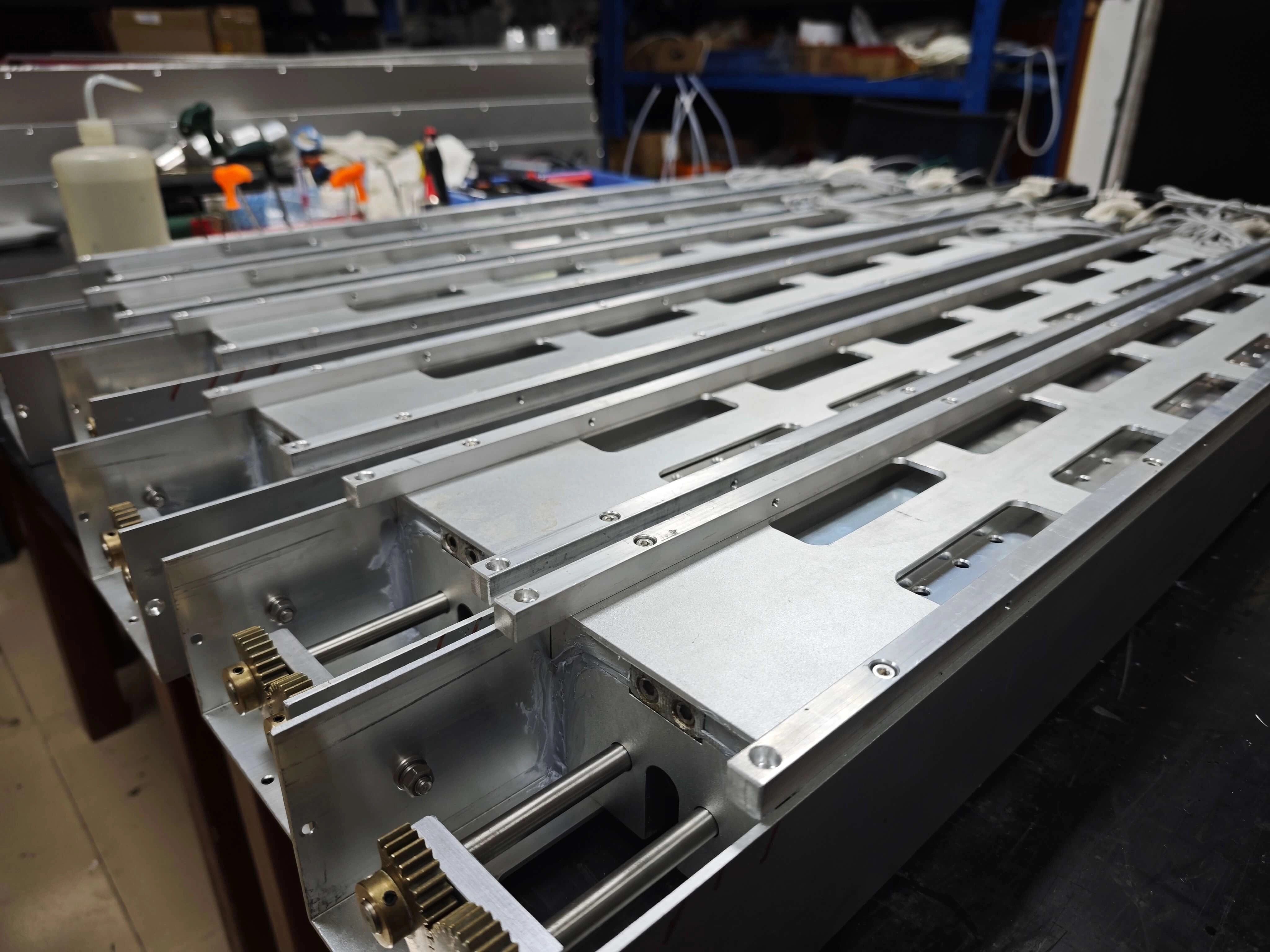

Vtech’s water-cooled UV curing systems offer superior temperature control, making them ideal for extended operation and high-volume production. Their stability and efficiency meet the industry’s demands for continuous, high-performance curing, ensuring optimal results even in high-temperature environments.

-

LED UV Curing Systems:

-

With low energy consumption, reduced heat generation, and environmentally friendly design, Vtech’s LED UV curing systems minimize thermal impact on substrates, making them suitable for various materials. Their long lifespan and sustainable design align with today’s focus on eco-friendly production.

Reception and Collaboration Opportunities

During the event, Vtech’s booth attracted a large number of professionals who were eager to learn about the core technologies and advantages of Vtech’s UV curing systems. The team demonstrated how these innovative technologies enhance production efficiency, reduce energy consumption, and improve product quality. Many potential clients expressed strong interest in Vtech’s products, exploring options for future partnerships and deeper technical collaboration.

Throughout the exhibition, Vtech engaged in in-depth discussions with industry experts and potential clients, further expanding its brand influence in the international market and exploring future collaboration opportunities. This exhibition allowed Vtech to once again demonstrate its expertise and leadership in UV curing technology.

Looking Ahead

Looking forward, Vtech will continue to invest in research and development within the UV curing field, dedicated to providing high-quality products and services to clients worldwide. Embracing a spirit of innovation, Vtech aims to drive growth in the printing and packaging industries, helping clients achieve more efficient and sustainable production. The 2024 Drupa International Printing Exhibition was not only an opportunity to showcase new products but also a valuable platform to stay informed about industry trends and expand Vtech’s presence in global markets. Vtech looks forward to building partnerships that advance the future of the printing industry.

We extend our gratitude to all the clients and partners who supported us during the event. Vtech is committed to delivering top-quality UV curing solutions worldwide and contributing to the sustainable development of the industry.

Summary

At the 2024 Drupa International Printing Exhibition, Vtech Co., Ltd. Guangzhou showcased its latest advancements in UV curing technology, including water-cooled and LED UV curing systems. These innovative solutions highlight Vtech’s commitment to efficiency, sustainability, and product quality in the printing industry. The event not only attracted a significant number of industry professionals to Vtech’s booth but also opened up new opportunities for collaboration. Vtech's presence at Drupa 2024 reaffirmed its position as a leading provider of UV curing solutions, poised to meet the evolving needs of the global printing and packaging sectors.

FAQs

-

What is the Drupa International Printing Exhibition, and why is it important for Vtech?

The Drupa International Printing Exhibition is one of the world’s largest and most influential events for the printing and packaging industry. It provides a global platform for companies like Vtech to showcase innovations, connect with industry professionals, and explore potential partnerships. -

What products did Vtech present at Drupa 2024?

Vtech showcased its advanced water-cooled UV curing systems and LED UV curing systems, both of which are designed to offer high efficiency, energy savings, and consistent quality for a wide range of printing applications. -

What are the advantages of Vtech’s water-cooled UV curing system?

The water-cooled UV curing system offers superior temperature control, making it ideal for long, continuous printing runs. This system is designed to prevent overheating, ensuring reliable and stable performance even under high-demand conditions. -

How does Vtech’s LED UV curing system support sustainability in printing?

Vtech’s LED UV curing system consumes less energy, produces minimal heat, and has a longer lifespan compared to traditional systems. Its design minimizes environmental impact, aligns with sustainability goals, and allows for high-quality curing across various materials. -

What support does Vtech offer to international clients interested in its products?

Vtech provides full after-sales support, including technical assistance, maintenance guidance, and warranty options. Our team works closely with clients worldwide to help them get the best performance from our UV curing systems and ensure long-term operational efficiency.

2025 Jakarta Printing Exhibition in Indonesia(All Print Indonesia)

Vietnam Print Pack 2025 Concludes Successfully: Innovative Water-Cooled UV Systems Lead New Trends in Green Printing

Post exhibition report: Water cooled UV/LED system shines at RoSupack 2025, promoting green and sustainable printing

How does UV technology make your product stand out?

The 11th Beijing International Printing Technology Exhibition Concluded Successfully, Vtech.Co.,Ltd.Guangzhou Achieved Fruitful Results

Vtech water-cooled UV/LED system helps Roland 300 printing machine upgrade efficiency again!

You may also like

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang