High-Quality LED Ink Curing Systems | Vtech Co., Ltd

Introduction

Vtech Co., Ltd, established in 2006, is a leading enterprise in the development and production of water-cooled UV curing systems and LED UV curing systems. With a focus on innovation and quality, we have secured numerous patents in the industry, offering reliable service and efficient production for various printing processes.

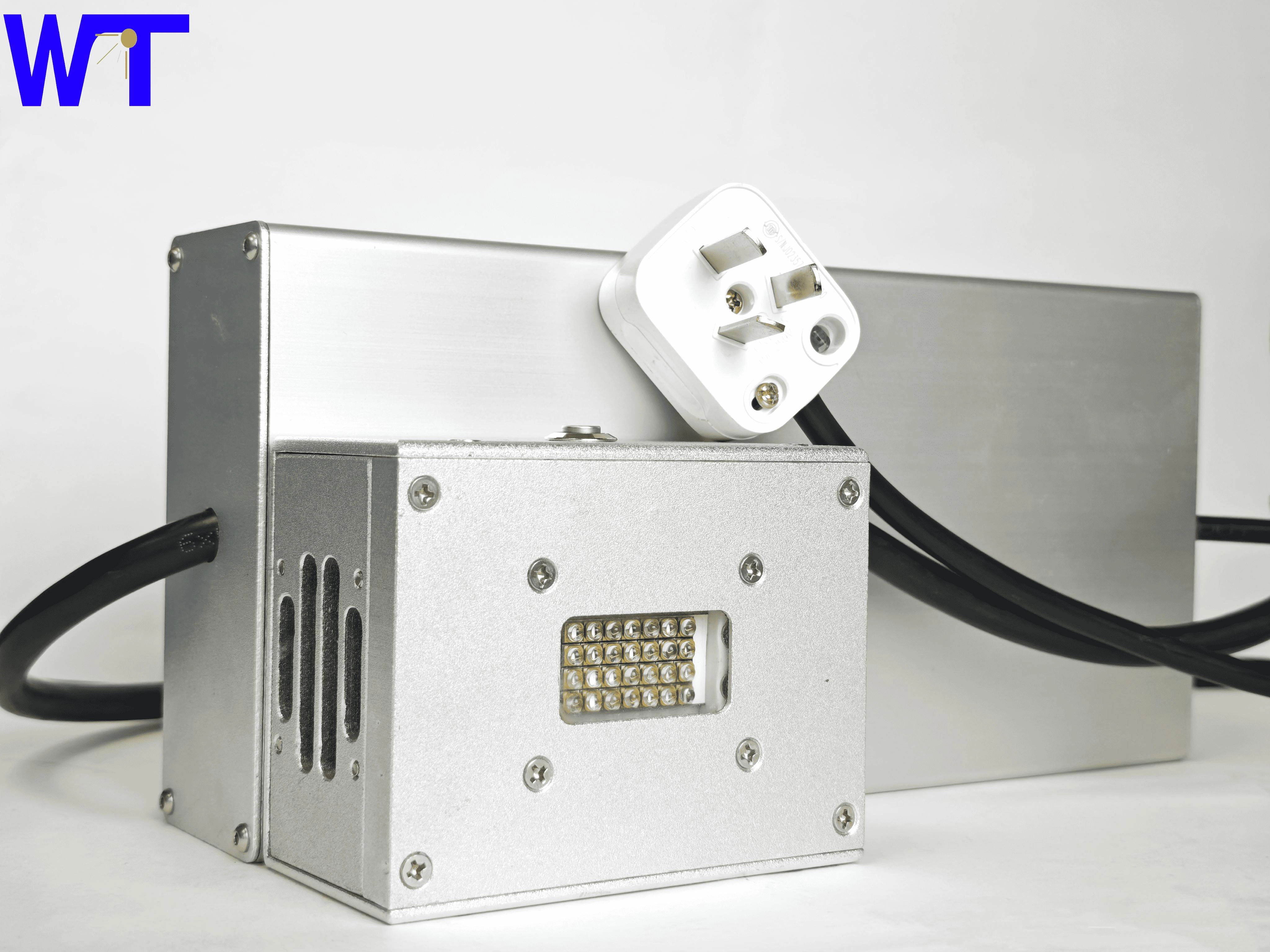

Advanced LED Ink Curing Systems

Our LED UV curing systems are designed to provide advanced ink curing solutions for offset press, gravure press, flexo press, coatings, and silk screen print applications. With cutting-edge technology, our systems offer precise and uniform curing, enhancing the overall printing quality and efficiency.

Efficient and Cost-Effective Solutions

At Vtech Co., Ltd, we prioritize the development of efficient and cost-effective LED UV curing systems. Our products are engineered to optimize energy consumption while maximizing curing performance, resulting in lower operational costs for our clients without compromising on quality.

Customized Solutions

We understand that different printing processes require specific curing solutions. That’s why we offer customized LED UV curing systems tailored to the unique needs of our clients. Our team of experts works closely with customers to develop and produce systems that align with their production requirements.

Reliable Performance and Durability

With our rich experience and expertise in UV and LED curing technology, our systems are built to deliver reliable performance and durability. Whether it’s high-speed printing or demanding applications, our products are designed to withstand the rigors of industrial operations.

Enhanced Printing Quality

By utilizing our LED UV curing systems, customers can achieve enhanced printing quality with vibrant colors, crisp details, and improved adhesion. The precise curing technology ensures consistent results, making it a valuable investment for businesses looking to elevate their printing standards.

Sustainable and Eco-Friendly Solutions

We are committed to sustainability and environmental responsibility. Our LED UV curing systems promote eco-friendly practices by eliminating the need for heat and harmful chemicals, reducing emissions, and providing a safer working environment for operators.

Comprehensive Support and Service

At Vtech Co., Ltd, we offer comprehensive support and service to ensure the seamless integration and optimal performance of our LED UV curing systems. From installation and training to maintenance and troubleshooting, our team is dedicated to providing reliable assistance for our clients.

Conclusion

With our dedication to innovation, reliability, and customer satisfaction, Vtech Co., Ltd stands as a trusted partner for businesses seeking high-quality LED UV curing systems. Explore our range of products and experience the difference in your printing operations.

End of product description.

What is the major advantages of UV LED curing system’s than other UV curing system?

What's the whole UV LED curing system including?

How does your factory do the quality control?

lf the light intensity is adjustable?

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipmentWhy Does Varnish Turn Yellow? Professional Anti-Yellowing Solutions for Printing & Coating Industries

This article details the 4 core causes of varnish yellowing and provides a full-process anti-yellowing plan covering material selection, process optimization, and storage protection.

Comprehensive Guide to UV Lamp Fusing and Bending Issues: Causes, Solutions & Prevention

This article focuses on two common faults of UV lamps: fusing and bending. It briefly analyzes their causes and provides emergency treatment, repair points and long-term prevention measures, offering practical references for UV lamp use and maintenance.

Guangzhou Weitai Electromechanical Invites You to 2025 Shenzhen International Film & Tape Expo to Explore Innovative Water-Cooled UV/LED System

As a professional manufacturer of water-cooled UV/LED systems, Guangzhou Weitai Electromechanical Co., Ltd. sincerely invites you to the 2025 Shenzhen International Film & Tape Expo (FILM & TAPE EXPO 2025). Our booth number is 12C136, and the exhibition will be held from October 28th to 30th, 2025 at the Shenzhen World Exhibition & Convention Center (Bao'an).

The core components and operation process of UV system (In offset printing press)

This article focuses on the operation mechanism of UV systems for offset printing machines. Starting with core values, it details the advantages of UV systems in rapid curing, multi-substrate compatibility, and print quality improvement. It then breaks down the five core components of the system (UV light source, reflector cover, cooling system, etc.) and their functions. Finally, it analyzes key operation links step by step, including ink supply, UV curing, cooling inspection, and post-maintenance. It provides clear technical references for printing industry practitioners and equipment operators, helping them understand how UV systems break through the limitations of traditional drying technologies and adapt to special printing needs such as packaging and labeling.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang