The Ultimate Guide to UV Curing Systems for Efficient Production - Vtech Co., Ltd

s:

1. Introduction to UV Curing Systems

- Explanation of how UV curing systems work in the printing and coating industry

- Benefits of using UV curing systems such as faster curing times, energy efficiency, and enhanced productivity

2. Types of UV Curing Systems

- Differentiating between water-cooled UV curing systems and LED UV curing systems

- Advantages and applications of each type of UV curing system for various printing and coating processes

3. Features of Vtech Co., Ltd's UV Curing Systems

- Overview of Vtech Co., Ltd's expertise in research, development, and production of UV and LED curing systems

- Introduction to the company's patented technology and diverse product line for offset press, gravure press, flexo press, coatings, and silk screen print

4. Benefits of Using Vtech Co., Ltd's UV Curing Systems

- Detailed description of the advantages of using Vtech Co., Ltd's UV curing systems in terms of reliability, efficiency, and improved production outcomes

- Case studies and testimonials from satisfied clients who have experienced the benefits of Vtech Co., Ltd's UV curing systems

5. WT Brand and Vtech Co., Ltd's UV Curing Systems

- Introduction to the WT brand and its association with Vtech Co., Ltd's UV curing systems

- Explanation of the high-quality standards and innovation behind the WT brand for UV curing technology

6. Applications and Industries Served

- Examples of specific applications and industries that can benefit from using Vtech Co., Ltd's UV curing systems

- Detailed insights into how UV curing systems can optimize production processes for different printing and coating applications

7. Customer Support and Service Excellence

- Information on Vtech Co., Ltd's commitment to providing reliable service and support for customers using their UV curing systems

- Description of the company's rich experience and expertise in delivering efficient UV curing solutions for diverse production needs

8. Conclusion

- Recap of the significant advantages of using UV curing systems for efficient and high-quality production

- Call to action for businesses to explore Vtech Co., Ltd's extensive range of UV curing systems for enhancing their production processes

FAQs:

1. Q: What sets Vtech Co., Ltd's UV curing systems apart from other brands?

A: Vtech Co., Ltd's UV curing systems stand out for their patented technology, diverse product line, and proven reliability in enhancing production efficiency.

2. Q: Can Vtech Co., Ltd's UV curing systems be customized for specific production requirements?

A: Yes, Vtech Co., Ltd offers customization options to tailor their UV curing systems to meet the specific needs of different printing and coating applications.

3. Q: How does the WT brand differentiate Vtech Co., Ltd's UV curing systems in the market?

A: The WT brand is synonymous with high-quality standards and innovation, ensuring that Vtech Co., Ltd's UV curing systems deliver superior performance and efficiency.

4. Q: What kind of customer support does Vtech Co., Ltd provide for their UV curing systems?

A: Vtech Co., Ltd is committed to providing reliable service and efficient support for customers, leveraging their rich experience and expertise in the UV curing industry.

5. Q: How can businesses get in touch with Vtech Co., Ltd to learn more about their UV curing systems?

A: Businesses can contact Vtech Co., Ltd through their official website or reach out to their dedicated customer service team for inquiries about UV curing systems and solutions.

OEM/ODM uv spot curing system Manufacturers and supplier

China Top led uv curing system for printing Manufacturers and suppliers in China

WT best professional uv curing lamp Manufacturers supplier brand

The Ultimate Guide to UV Ink Curing Systems: A Detailed Overview of Vtech Co., Ltd

normal

Can I use my own PLC and Electric cabinet?

How to cooperate with you and what is the cooperation process?

What should I do when I don’t really know how to setting the printer parameters?

How long will take for mass production?

How to proceed an order for UV LED curing system?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

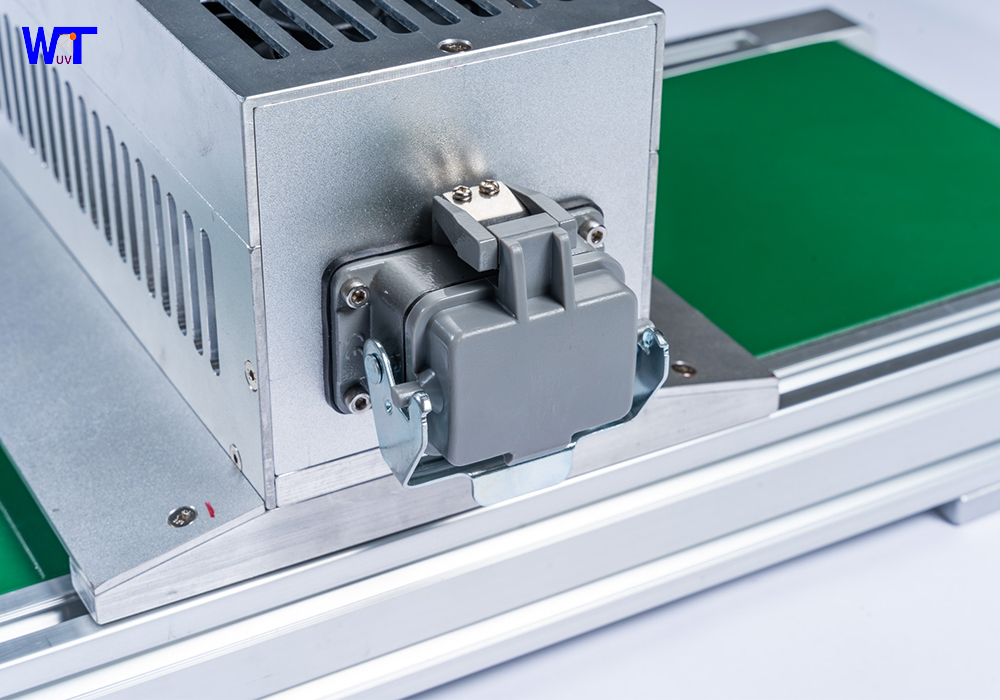

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang