The Ultimate Guide to UV Ink Curing Systems: A Detailed Overview of Vtech Co., Ltd

Introduction to Vtech Co., Ltd

Established in 2006, Vtech Co., Ltd is a reputable enterprise specializing in the research, development, and production of high-quality UV curing systems. With a strong emphasis on innovation and reliability, Vtech has secured numerous patents in the industry, making them a trusted partner for businesses seeking efficient and advanced curing solutions.

Water-Cooled UV Curing Systems

Vtech's water-cooled UV curing systems are designed to provide exceptional performance and consistency across various printing and coating applications. By leveraging advanced cooling technologies, these systems ensure optimal curing results while maintaining operational reliability and longevity.

Experience the next level of UV curing technology with Vtech's LED UV curing systems. Engineered for energy efficiency and precision, these cutting-edge systems offer unmatched flexibility and productivity for a wide range of printing processes. Discover how Vtech's LED UV curing solutions can elevate your production capabilities.

Applications and Expertise

Vtech's expertise extends to diverse applications, including offset press, gravure press, flexo press, coatings, silk screen print, and more. Their in-depth knowledge and experience in UV ink curing enable them to cater to the specific requirements of different industries, ensuring optimized performance and quality output.

Innovation and Reliability

Backed by a culture of constant innovation, Vtech continues to pioneer advancements in UV curing technology, pushing the boundaries of efficiency and effectiveness. Their unwavering commitment to reliability and customer satisfaction has established them as a preferred choice for businesses seeking high-performance curing solutions.

H4: The WT Brand

Vtech's WT brand represents a hallmark of quality and excellence in UV curing systems. With a focus on delivering reliable service and efficient production, the WT brand embodies Vtech's dedication to meeting the evolving needs of the printing and coating industry.

Conclusion:

In conclusion, Vtech Co., Ltd stands as a prominent figure in the realm of UV ink curing systems, offering a diverse range of solutions tailored to meet the demands of modern production environments. From water-cooled systems to LED UV technology, Vtech's commitment to innovation, reliability, and expertise shines through in their products and services. Whether you're in the offset press, flexo press, or silk screen print industry, Vtech's cutting-edge solutions can elevate your capabilities and drive your business forward.

FAQs:

1. What sets Vtech's UV curing systems apart from others in the market?

- Vtech's UV curing systems boast advanced cooling technologies and LED UV technology, ensuring superior performance, energy efficiency, and precise curing results.

2. How can Vtech's UV curing systems benefit my business?

- Vtech's UV curing systems are designed to enhance production efficiency and quality, catering to a wide range of printing and coating applications.

3. Does Vtech offer customized UV curing solutions for specific industry requirements?

- Yes, Vtech leverages its rich experience and expertise to provide tailored UV curing solutions for industries such as offset press, flexo press, gravure press, coatings, and silk screen print.

4. What is the significance of the WT brand in Vtech's UV curing systems?

- The WT brand represents Vtech's commitment to reliable service and efficient production, embodying their dedication to meeting the evolving needs of the printing and coating industry.

Why choose WT uv curing system and process manufacturer

Understanding the Power of UV Curing Systems in Printing

OEM/ODM uv spot curing system Manufacturers and supplier

Revolutionizing Printing with UV LED Curing Systems – Vtech Co., Ltd

normal

How long will take for mass production?

Where is your factory located?

Which wavelength do I need?

Can you do a design for me or company?

What's the whole UV LED curing system including?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

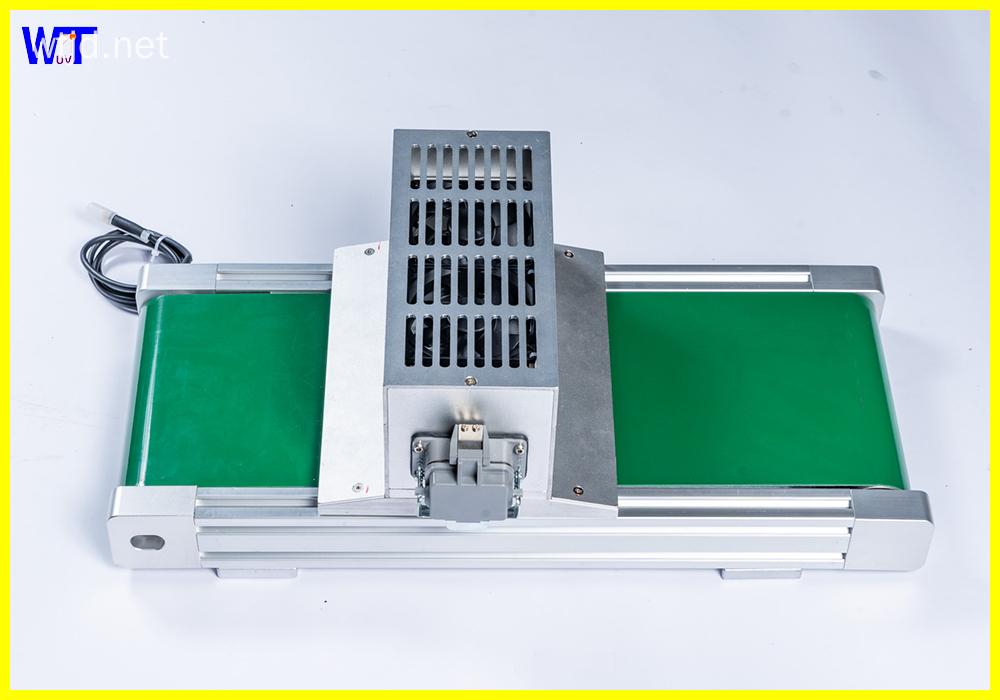

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang