Professional LED UV Curing System for Reliable and Quick Curing

Introducing our cutting-edge LED UV curing system, designed to revolutionize the way you cure coatings and inks. With our state-of-the-art technology, you can trust in the reliability and professionalism of our product to deliver superior results every time. Our user-friendly system ensures peace of mind, allowing you to easily and efficiently complete your curing processes with ease.

Our LED UV curing system is backed by years of expertise in product operations, providing you with a solution that not only meets your needs but exceeds your expectations. The advanced technology utilized in our system allows for quick and thorough curing, saving you time and providing a finished product of the highest quality.

With a focus on usability and efficiency, our LED UV curing system is designed to meet the demands of modern manufacturing processes. Whether you are in the automotive, electronics, or packaging industry, our product will enhance your production line and deliver unmatched results.

Say goodbye to traditional curing methods and embrace the future with our LED UV curing system. Trust in our product to provide the professional results you need, while offering ease of use and reliability.

Product Image

Our Advantages

1. The conveyor speed can adjustment according to the products drying condition;

We have over 17 years experience in UV curing industry.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

LEDs do not produce ozone gas.

Frequently Asked Questions

Where is your factory located?

What is the major advantages of UV LED curing system’s than other UV curing system?

Which wavelength do I need?

How about the after service?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

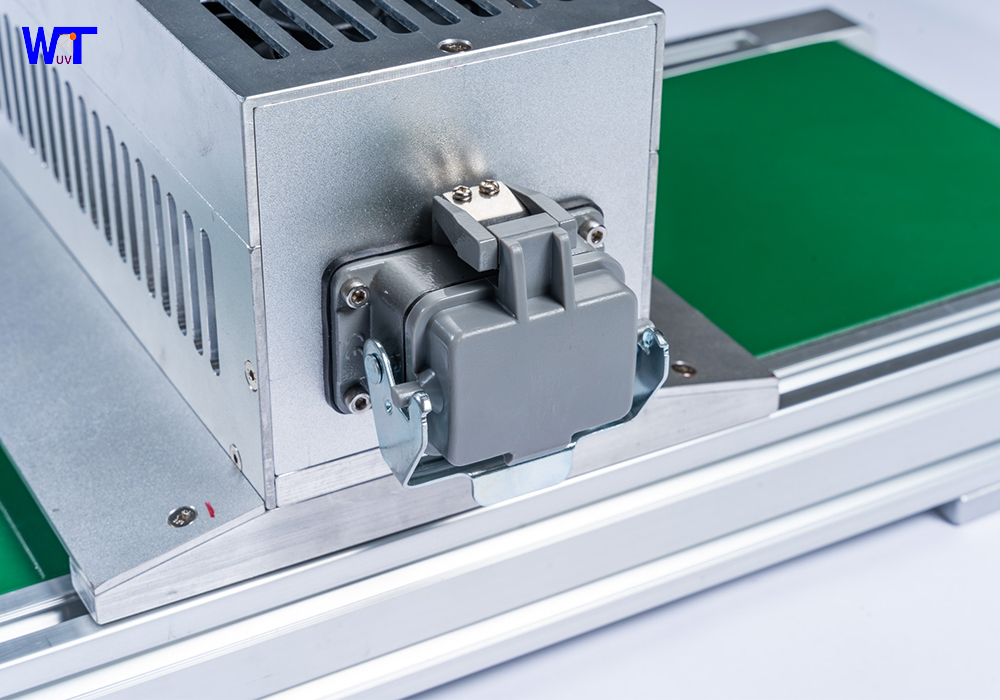

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang