OEM/ODM uv ink curing systems Manufacturers and supplier

Selecting OEM/ODM UV Ink Curing Systems Manufacturers and Suppliers

In today's dynamic printing and coating industry, UV ink curing systems have redefined efficiency and quality. As a business considering an upgrade or expansion, choosing the right OEM/ODM manufacturers and suppliers is critical. Established in 2006, Vtech Co., Ltd stands as an industry pioneer, offering innovative solutions in UV and LED curing technologies. But why should tailored OEM/ODM UV ink curing systems be your next investment? Let's explore.

Understanding UV Ink Curing Systems

UV ink curing systems transform liquid ink into a solid state using ultraviolet light, offering faster drying times, enhanced durability, and eco-friendliness. These systems are indispensable for various industrial applications, including offset printing, gravure press, flexo printing, coatings, and silk screen printing.

Why Choose Vtech Co., Ltd?

Vtech Co., Ltd specializes in both water-cooled and LED UV curing systems, leveraging rich expertise accumulated since 2006. Our commitment to research and development, backed by numerous patents, positions us as innovators in the field. This ensures our clients receive state-of-the-art solutions tailored to their specific needs.

Key Advantages of Our UV Curing Systems

1. Versatility: Our systems are adept at handling various presses and coating types, providing seamless integration across several applications.

2. Efficiency: Proprietary technology ensures faster processing times without compromising quality, leading to increased productivity and minimized downtime.

3. Sustainability: Our systems are designed to minimize energy consumption, fostering an eco-friendly footprint and reducing operational costs.

Factors to Consider When Selecting a Manufacturer/Supplier

1. Expertise: Look for companies with a solid track record and specialized knowledge in UV or LED technologies.

2. Innovation: Choose a partner that invests in R&D and holds relevant patents, ensuring cutting-edge solutions.

3. Support: Opt for manufacturers offering comprehensive customer service, from installation to maintenance and troubleshooting.

FAQs

1. What is OEM/ODM in UV curing systems?

OEM (Original Equipment Manufacturer) refers to systems made to another company's specifications. ODM (Original Design Manufacturer) systems are researched, designed, and produced in-house, offering customizable solutions to meet client demands.

2. Are LED UV curing systems better than water-cooled systems?

LED and water-cooled systems each have unique advantages. LED systems are more energy-efficient and have a longer lifecycle, while water-cooled units are often more robust and better suited for high-capacity operations.

3. How do UV curing systems benefit the environment?

UV curing systems substantially reduce volatile organic compound (VOC) emissions, consume less energy, and generate less waste, making them an eco-friendly choice.

Conclusion

Choosing the right OEM/ODM UV ink curing systems manufacturer is crucial in achieving operational excellence. With Vtech Co., Ltd, you gain access to superior technology, expertise, and a commitment to sustainable growth. Trust us to enhance your printing and coating operations with reliable, innovative solutions.

For inquiries or more information about our products and services, feel free to contact Vtech Co., Ltd today. Experience the future of UV curing technology with a partner you can rely on.

The Ultimate Guide to UV Lamp Cure: The Best Solution for Efficient Production

WT best professional uv curing lamps Manufacturers supplier brand

Ultraviolet Light Curing: A Complete Guide to WT's Innovative Technology

Uncovering the Magic of WT UV Cure Adhesive: How Does it Work?

normal

What's the Peak Irradiance do I need?

When can I get the quotations?

How about the after service?

What should I do when I don’t really know how to setting the printer parameters?

Why and how do I replace a UV led?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

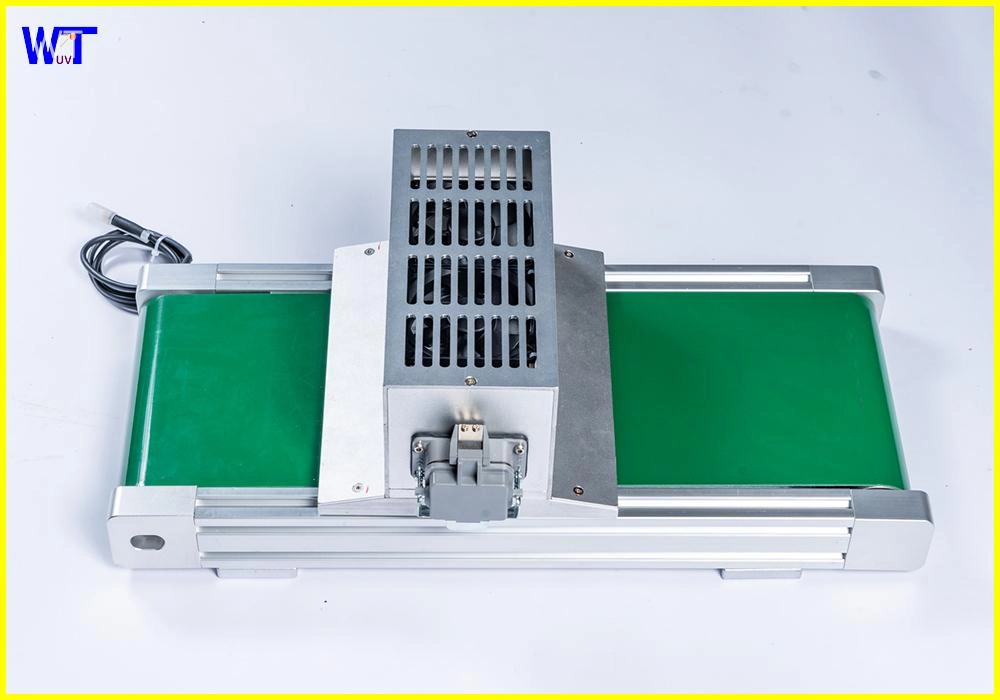

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang