High-Quality Automated UV Curing Systems | Water-Cooled & LED

Product Descriptions:

Introduction

At our company, we are proud to offer top-tier automated UV curing systems that are designed to meet the needs of the printing industry. With over a decade of experience, we have established ourselves as a leader in the research, development, and production of water-cooled UV curing systems and LED UV curing systems. Our dedication to innovation and commitment to quality has resulted in numerous patents and a diverse range of reliable UV and LED curing solutions for various printing processes.

Water-Cooled UV Curing Systems

Our water-cooled UV curing systems are engineered to provide efficient and consistent curing for offset presses, gravure presses, flexo presses, coatings, silk screen prints, and more. With advanced technology and precision engineering, our water-cooled systems deliver powerful UV output to ensure fast and reliable curing, resulting in enhanced productivity and superior print quality. Whether you are printing on paper, film, or other substrates, our water-cooled UV curing systems are designed to meet your specific needs with unparalleled performance and durability.

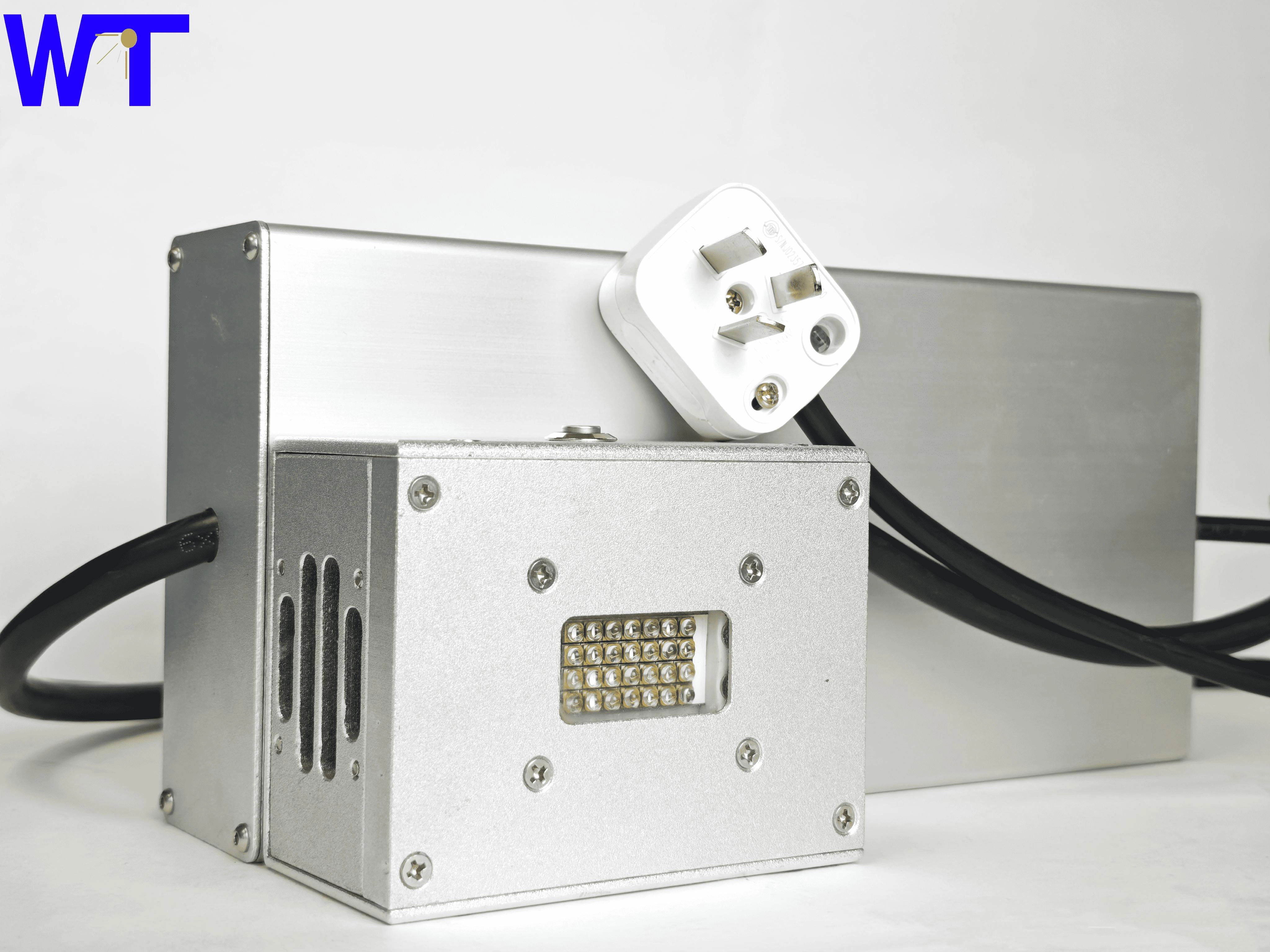

LED UV Curing Systems

In response to the growing demand for energy-efficient and eco-friendly printing solutions, we have developed a range of cutting-edge LED UV curing systems. These systems utilize the latest advancements in LED technology to deliver high-intensity UV output with reduced energy consumption and environmental impact. From instant on/off capabilities to long-lasting LED modules, our LED UV curing systems provide a sustainable and cost-effective solution for achieving fast curing and exceptional printing results. With customizable options and seamless integration, our LED UV curing systems are tailored to optimize your production process while minimizing operational costs.

Expertise and Service

As a trusted provider of UV curing solutions, we understand the importance of reliable service and support for our customers. Our team of industry experts is dedicated to assisting you in selecting the right UV curing system for your specific application, as well as providing comprehensive technical guidance and hands-on assistance. Additionally, we offer maintenance services and spare parts to ensure the ongoing performance and longevity of your UV curing systems. With our in-depth knowledge and practical experience, we are committed to delivering the highest level of service to meet your production requirements and exceed your expectations.

Conclusion

In conclusion, our automated UV curing systems are the result of years of research, development, and innovation, leading to the creation of industry-leading solutions that are tailored to the evolving needs of the printing industry. Whether you choose our water-cooled UV curing systems or our LED UV curing systems, you can rely on our expertise and dedication to deliver reliable performance, efficient production, and exceptional print quality. Experience the difference with our automated UV curing systems and discover the benefits of advanced technology and reliable service.

What's the Peak Irradiance do I need?

Are you a trader or manufacturer?

What should I do when I don’t really know how to setting the printer parameters?

how can we guarantee quality?

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipmentPaper Saved! Vtech.UV & EZ Gravteck Solve Printing Industry Cost Pain Point

Vtech.UV & EZ Gravteck cut packaging gravure gripper shadow to 13mm via UV+mechanical optimization, fitting high-end packaging for cost reduction & compliance.

Why Does Varnish Turn Yellow? Professional Anti-Yellowing Solutions for Printing & Coating Industries

This article details the 4 core causes of varnish yellowing and provides a full-process anti-yellowing plan covering material selection, process optimization, and storage protection.

Comprehensive Guide to UV Lamp Fusing and Bending Issues: Causes, Solutions & Prevention

This article focuses on two common faults of UV lamps: fusing and bending. It briefly analyzes their causes and provides emergency treatment, repair points and long-term prevention measures, offering practical references for UV lamp use and maintenance.

Guangzhou Weitai Electromechanical Invites You to 2025 Shenzhen International Film & Tape Expo to Explore Innovative Water-Cooled UV/LED System

As a professional manufacturer of water-cooled UV/LED systems, Guangzhou Weitai Electromechanical Co., Ltd. sincerely invites you to the 2025 Shenzhen International Film & Tape Expo (FILM & TAPE EXPO 2025). Our booth number is 12C136, and the exhibition will be held from October 28th to 30th, 2025 at the Shenzhen World Exhibition & Convention Center (Bao'an).

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang