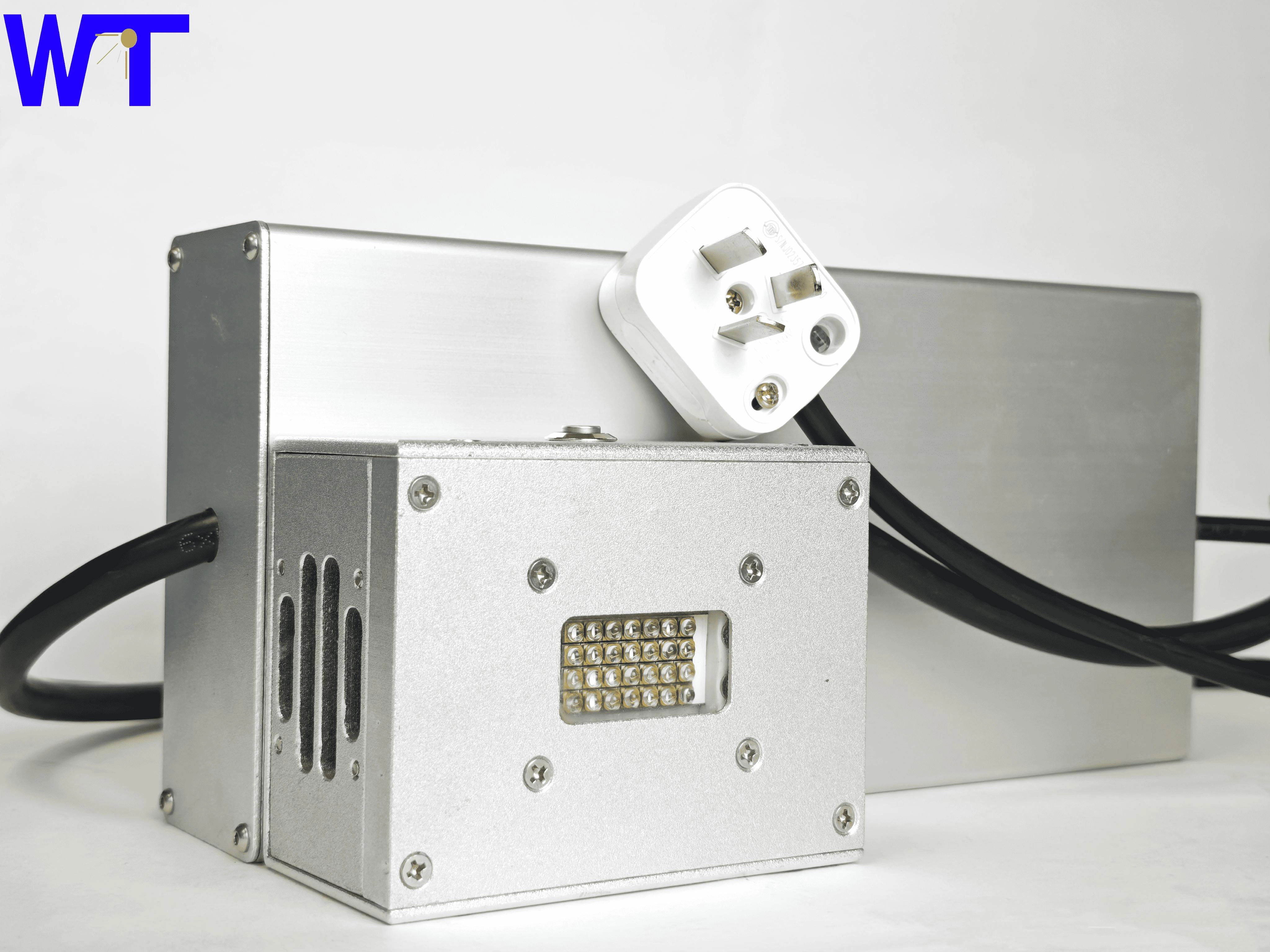

WT Brand UV Lamp Curing - Ultra-Fast, Efficient and Durable

Introducing WT Brand UV Lamp Curing, the ultimate solution for accelerated and efficient curing processes. With its cutting-edge technology and superior performance, WT Brand UV Lamp Curing is the choice for professionals seeking fast and durable results. Whether you are in the automotive, medical, or industrial industry, our UV lamp curing system is designed to meet your specific needs.

One of the key advantages of our WT Brand UV Lamp Curing is its ultra-fast curing time. With our state-of-the-art UV lamps, your curing process will be completed in a fraction of the time compared to conventional methods. Say goodbye to long waiting periods and hello to increased productivity. Our UV lamps emit high-intensity ultraviolet light, which instantly cures coatings, adhesives, and other materials. This means you can move on to the next step of your process faster, saving valuable time and resources.

Efficiency is at the core of our WT Brand UV Lamp Curing. Our lamps are designed with advanced features that ensure optimal performance and energy utilization. With adjustable settings and precise control, you can customize the curing cycle to suit your specific requirements. This flexibility allows for consistent and reliable results every time. Additionally, our UV lamps are built to last, reducing the need for frequent replacements and saving you money in the long run.

Transitioning from traditional curing methods to WT Brand UV Lamp Curing is seamless. Our lamps can be easily integrated into existing production lines, minimizing any disruptions to your workflow. The user-friendly interface and intuitive controls ensure a hassle-free experience for operators. With minimal training required, you can start benefiting from our UV lamp curing system right away.

Take your curing process to new heights with WT Brand UV Lamp Curing. Unlock the power of our innovative technology and experience the benefits of fast, efficient, and durable curing. Increase your productivity and improve your bottom line today. Contact us to learn more about how WT Brand UV Lamp Curing can elevate your business.

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipment

Customized conveyor belt type UV LED curing equipmentWhy Does Varnish Turn Yellow? Professional Anti-Yellowing Solutions for Printing & Coating Industries

This article details the 4 core causes of varnish yellowing and provides a full-process anti-yellowing plan covering material selection, process optimization, and storage protection.

Comprehensive Guide to UV Lamp Fusing and Bending Issues: Causes, Solutions & Prevention

This article focuses on two common faults of UV lamps: fusing and bending. It briefly analyzes their causes and provides emergency treatment, repair points and long-term prevention measures, offering practical references for UV lamp use and maintenance.

Guangzhou Weitai Electromechanical Invites You to 2025 Shenzhen International Film & Tape Expo to Explore Innovative Water-Cooled UV/LED System

As a professional manufacturer of water-cooled UV/LED systems, Guangzhou Weitai Electromechanical Co., Ltd. sincerely invites you to the 2025 Shenzhen International Film & Tape Expo (FILM & TAPE EXPO 2025). Our booth number is 12C136, and the exhibition will be held from October 28th to 30th, 2025 at the Shenzhen World Exhibition & Convention Center (Bao'an).

The core components and operation process of UV system (In offset printing press)

This article focuses on the operation mechanism of UV systems for offset printing machines. Starting with core values, it details the advantages of UV systems in rapid curing, multi-substrate compatibility, and print quality improvement. It then breaks down the five core components of the system (UV light source, reflector cover, cooling system, etc.) and their functions. Finally, it analyzes key operation links step by step, including ink supply, UV curing, cooling inspection, and post-maintenance. It provides clear technical references for printing industry practitioners and equipment operators, helping them understand how UV systems break through the limitations of traditional drying technologies and adapt to special printing needs such as packaging and labeling.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang