The Ultimate Guide to Industrial UV Light: Everything You Need to Know

Introduction

In recent years, industrial UV light has gained significant traction as a powerful and versatile tool in various industries. From printing and coatings to medical and electronics, the applications of UV curing systems are diverse and wide-ranging. In this guide, we will delve into the world of industrial UV light and explore its applications, benefits, and key considerations that can revolutionize your business processes.

Understanding Industrial UV Light

Industrial UV light, also known as ultraviolet light, is a form of electromagnetic radiation that is invisible to the human eye. UV light has a shorter wavelength than visible light, making it highly energetic and capable of triggering photochemical reactions. This unique property makes UV light an ideal choice for curing processes in industries such as printing, coatings, and electronics.

Applications of Industrial UV Light

Industrial UV light finds widespread applications in various industries, thanks to its ability to initiate rapid curing processes. In the printing industry, UV curing systems are used to instantly dry inks on paper, resulting in faster production speeds and vibrant print quality. Similarly, in the coatings industry, UV light enables the quick and efficient curing of coatings on various substrates, leading to improved durability and performance.

Benefits of Industrial UV Light

The adoption of industrial UV light offers several compelling benefits for businesses. Firstly, UV curing systems enable rapid curing times, leading to increased production efficiency and reduced energy consumption. Secondly, UV-cured products exhibit enhanced durability and superior finish, resulting in higher quality outputs. Additionally, UV curing eliminates the need for solvents and drying agents, making it an environmentally friendly choice for businesses.

Key Considerations for Industrial UV Light

When integrating industrial UV light into your business processes, several key considerations should be taken into account. These include the selection of the appropriate UV wavelength, the compatibility of substrates with UV curing, and the overall system design and configuration. Understanding these considerations is crucial to maximizing the benefits of UV curing systems and ensuring optimal performance.

How Vtech Co., Ltd Revolutionizes Industrial UV Light with WT Brand

Vtech Co., Ltd is a leading enterprise specializing in the research, development, and production of water-cooled UV curing systems and LED UV curing systems. With a strong focus on innovation and quality, Vtech Co., Ltd has established numerous patents in the industry and continuously develops cutting-edge UV and LED curing systems for various applications.

One of the hallmark brands under Vtech Co., Ltd is WT, which represents a commitment to excellence and reliability in industrial UV light solutions. The WT brand offers a diverse range of UV and LED curing systems tailored to the specific needs of offset press, gravure press, flexo press, coatings, silk screen print, and other applications. With rich experience and expertise, Vtech Co., Ltd and the WT brand ensure reliable service and efficient production for businesses seeking to harness the power of industrial UV light.

Conclusion

In conclusion, industrial UV light has become an indispensable tool for businesses seeking to enhance their production processes and product quality. With its versatile applications, compelling benefits, and key considerations, UV curing systems have the potential to revolutionize various industries. By partnering with Vtech Co., Ltd and leveraging the innovative solutions offered under the WT brand, businesses can unlock the full potential of industrial UV light and stay ahead in today's competitive market.

FAQs

Q: What are the primary industries that benefit from industrial UV light?

A: Industrial UV light finds applications in industries such as printing, coatings, medical, electronics, and more.

Q: How does industrial UV light improve production efficiency?

A: UV curing systems enable rapid curing times, resulting in increased production efficiency and reduced energy consumption.

Q: What are the environmental benefits of using UV curing systems?

A: UV curing eliminates the need for solvents and drying agents, making it an environmentally friendly choice for businesses.

Q: What sets Vtech Co., Ltd and the WT brand apart in the industrial UV light industry?

A: Vtech Co., Ltd and the WT brand offer cutting-edge UV and LED curing systems with a focus on innovation, reliability, and efficient production.

The Complete Guide to Industrial UV Curing Systems: Everything You Need to Know

The Ultimate Guide to Fusion UV Curing Systems for Efficient Marketing

Revolutionize Screen Printing with UV Curing System | WT

The Ultimate Guide to UV Flood Curing Systems | Vtech Co., Ltd

normal

Can you do a design for me or company?

What's the cooling way?

What materials can UV printers print?

how can we guarantee quality?

What is the major advantages of UV LED curing system’s than other UV curing system?

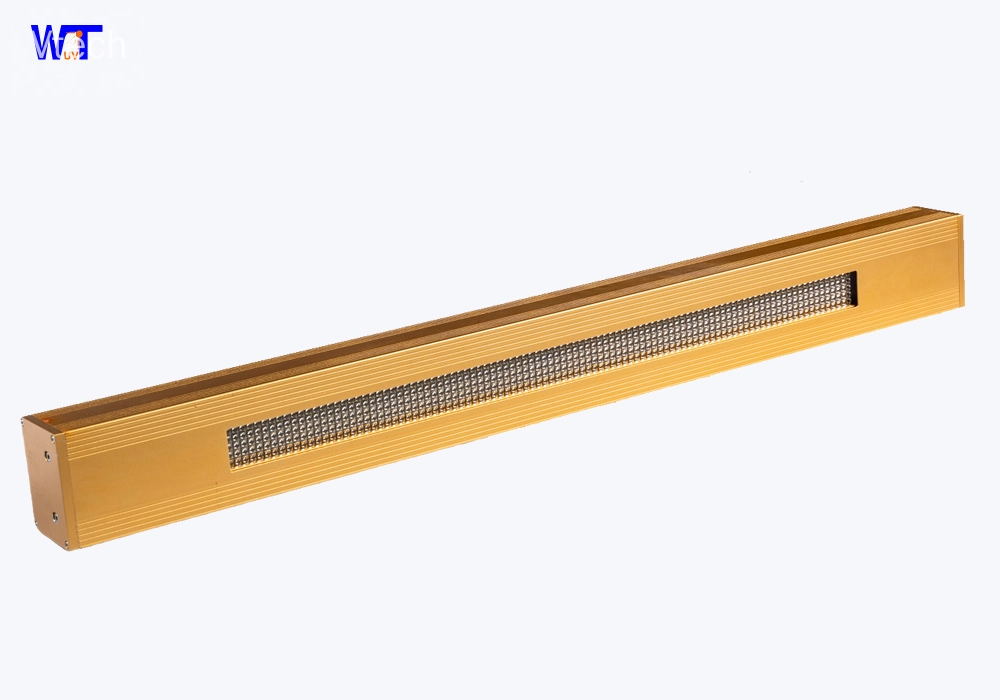

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang