WT LED UV Curing Systems for Printing

Unlock Superior Printing with WT LED UV Curing Systems

In today's fast-paced printing world, efficiency, quality, and sustainability are paramount. Vtech Co., Ltd, through our trusted WT brand, introduces the Highly Effective LED UV Curing Systems — engineered to transform your printing operations. Established in 2006, Vtech brings over 17 years of specialized expertise and patented innovations in UV curing technology directly to your press.

Unmatched Performance, Instant Results

Our WT LED UV Curing Systems deliver instant, precise curing, allowing for immediate post-press handling and significantly reducing production bottlenecks. This leads to faster turnaround times, increased throughput, and ly, greater profitability for your business. Whether you run an offset press, gravure press, flexo press, or handle coatings and silk screen prints, our systems are designed to integrate seamlessly, enhancing the efficiency of your existing setup.

Cost Savings & Environmental Responsibility

Experience a new era of energy efficiency. Unlike traditional UV lamps, WT LED systems consume significantly less power, translating into substantial long-term cost savings on electricity. The cooler operating temperatures extend component life, reduce maintenance needs, and eliminate the need for costly ventilation systems by producing no ozone. Embrace a greener operation with reduced VOC emissions, creating a safer and healthier working environment for your team.

Elevate Print Quality & Durability

Achieve crisp, vibrant, and highly durable prints every time. Our LED UV curing technology ensures excellent ink adhesion, sharper details, and superior scratch and chemical resistance. This consistent, high-quality output not only meets but exceeds customer expectations, strengthening WT's reputation for excellence.

Why Choose WT by Vtech?

With Vtech Co., Ltd, you're not just purchasing equipment; you're investing in a partnership backed by decades of research, development, and hands-on experience. Our many industry patents reflect our commitment to innovation and reliability. We understand the nuances of various printing applications and are dedicated to providing solutions that are not only practical and valuable but also tailored to meet your specific production needs.

Upgrade to WT Highly Effective LED UV Curing Systems and empower your printing business with advanced technology, sustainable practices, and unparalleled performance. Contact us today to discover how WT can elevate your production capabilities.

Detailed display

Our Advantages

24 Hours Service Hotline: All our team of service are fully conversant with our extensive range of products and can quickly and expertly talk you through any question you may ask. Vtech is committed to provide a 24 hours customer service/breakdown hotline in local office.

With stepless dimming function;

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

With line disconnection alarm and LED dead point detection alarm function.

Q&A

Can I use my own PLC and Electric cabinet?

What's the cooling way?

Can we visit the factory?

How to proceed an order for UV LED curing system?

If you have any questions or concern, please contact us.

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

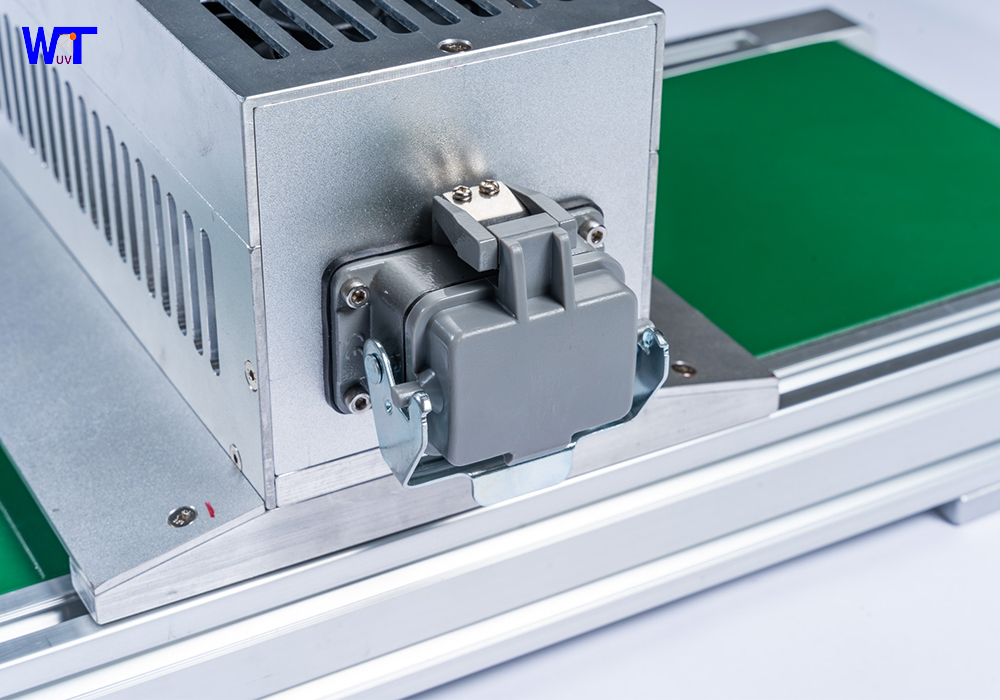

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang