What is uv curing systems

- What are UV Curing Systems? A Comprehensive Guide by Vtech Co., Ltd WT

- Understanding UV Curing Technology

- How UV Curing Systems Work: A Step-by-Step Process

- Types of UV Curing Systems Offered by Vtech Co., Ltd WT

- Water-Cooled UV Curing Systems: Superior Performance and Durability

- LED UV Curing Systems: Energy Efficiency and Environmental Friendliness

- Applications of UV Curing Systems Across Industries

- UV Curing in Printing: Offset, Gravure, and Flexo Printing

- UV Curing in Coatings: Enhanced Durability and Aesthetics

- UV Curing in Silk Screen Printing: Precision and Detail

- Advantages of Choosing Vtech Co., Ltd WT's UV Curing Systems

- Choosing the Right UV Curing System: Factors to Consider

- Frequently Asked Questions (FAQ)

- Conclusion: Partner with Vtech Co., Ltd WT for Superior UV Curing Solutions

What are UV Curing Systems? A Comprehensive Guide by Vtech Co., Ltd WT

Understanding UV Curing Technology

UV curing, also known as ultraviolet curing, is a photochemical process that uses ultraviolet light to rapidly cure (polymerize) specialized inks, coatings, and adhesives. Unlike traditional thermal curing methods which rely on heat, UV curing utilizes specific photoinitiators within the material that absorb UV light, triggering a polymerization reaction that solidifies the material almost instantly. This speed and efficiency are key advantages driving its widespread adoption across diverse industries.

How UV Curing Systems Work: A Step-by-Step Process

The process begins with the application of a UV-curable material onto a substrate. This could be ink on paper, a coating on wood, or adhesive on a metal component. The material contains photoinitiators, light-sensitive molecules that initiate the polymerization process. A powerful UV lamp, part of the UV curing system, then emits high-intensity UV light. This light is absorbed by the photoinitiators, creating highly reactive free radicals. These free radicals trigger a chain reaction, causing the monomers (small molecules) in the UV-curable material to bond together, forming long polymer chains. This process rapidly solidifies the material, resulting in a cured finish. The speed of curing depends on factors like lamp intensity, material properties, and the thickness of the applied layer.

Types of UV Curing Systems Offered by Vtech Co., Ltd WT

Vtech Co., Ltd WT offers a comprehensive range of UV curing systems catering to various industrial applications. Our expertise extends to both water-cooled UV curing systems and LED UV curing systems.

Water-Cooled UV Curing Systems: Superior Performance and Durability

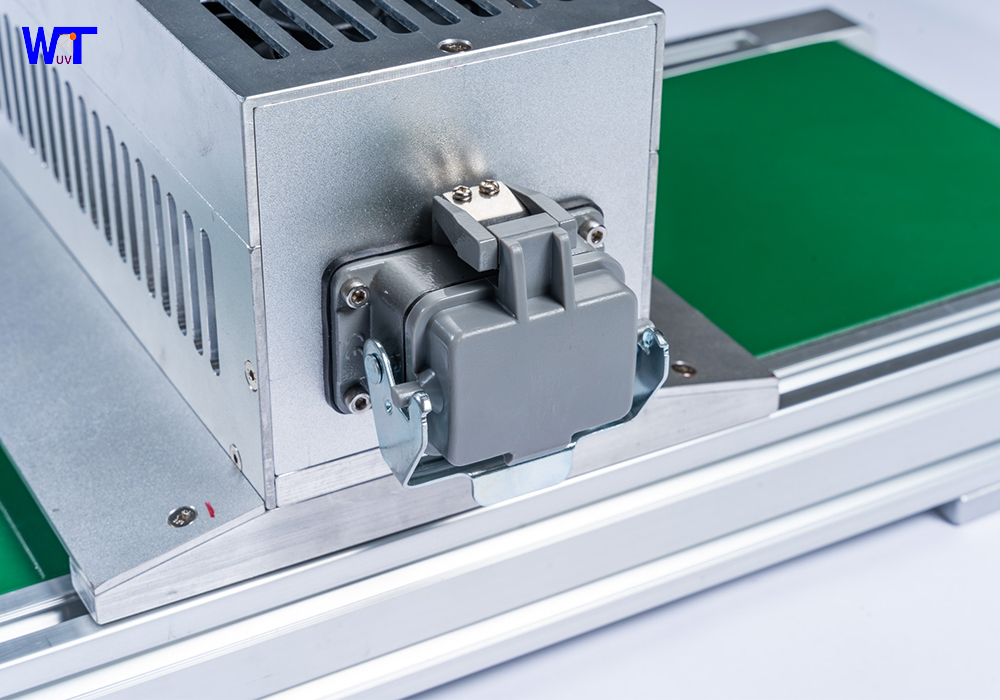

Our water-cooled UV curing systems are engineered for high-performance applications demanding consistent and reliable curing. The water-cooling system effectively manages the heat generated by the high-intensity UV lamps, ensuring prolonged lamp life and optimal curing efficiency. These systems are ideal for high-volume production environments and demanding industrial processes. We offer customized solutions to meet specific requirements, making us a leading provider of industrial UV curing equipment.

LED UV Curing Systems: Energy Efficiency and Environmental Friendliness

For businesses focused on sustainability and energy efficiency, our LED UV curing systems provide an excellent alternative. LED UV lamps consume significantly less energy than traditional mercury-vapor lamps, leading to lower operating costs and a reduced carbon footprint. Additionally, LED UV curing systems typically produce less heat, making them suitable for heat-sensitive substrates. They offer a long lifespan and consistent output, providing reliable performance over extended periods, reducing maintenance and replacement costs.

Applications of UV Curing Systems Across Industries

The versatility of UV curing systems makes them indispensable across a multitude of industries. Let's explore some key applications:

UV Curing in Printing: Offset, Gravure, and Flexo Printing

UV curing is revolutionizing the printing industry, particularly offset, gravure, and flexo printing processes. The instant curing provided by UV systems enhances productivity, reduces drying time, and allows for immediate further processing. This technology is especially beneficial for high-speed printing operations, where minimizing downtime is crucial. Our UV curing systems are meticulously engineered to seamlessly integrate with various printing presses, improving efficiency and print quality for businesses of all sizes. The instant drying feature eliminates the need for lengthy drying stages, boosting operational efficiency.

UV Curing in Coatings: Enhanced Durability and Aesthetics

UV curing is widely used in the application of protective coatings and decorative finishes across various substrates, including wood, metal, plastic, and paper. The speed and efficiency of UV curing lead to faster production cycles and reduced material waste. Furthermore, UV-cured coatings exhibit exceptional durability and resistance to chemicals, abrasion, and weathering, making them ideal for a range of applications, from automotive coatings to industrial finishes. Our systems guarantee uniform and high-quality coating applications.

UV Curing in Silk Screen Printing: Precision and Detail

In silk screen printing, UV curing systems provide precise and detailed curing of inks, enabling intricate designs and high-resolution prints on various materials. The instant drying minimizes smudging and ensures sharp, clear prints, enhancing the overall quality and appeal of the finished products. Our advanced UV curing solutions are designed to meet the specific requirements of silk screen printing applications, offering superior control and efficiency.

Advantages of Choosing Vtech Co., Ltd WT's UV Curing Systems

Vtech Co., Ltd WT stands apart as a leading provider of UV curing systems due to several key advantages:

* Cutting-edge technology: We employ the latest advancements in UV and LED curing technology to deliver superior performance and reliability.

* Customized solutions: We tailor our systems to meet the unique needs of each client, ensuring optimal integration and efficiency.

* High-quality components: We use only the highest-quality components in our systems, guaranteeing durability and longevity.

* Exceptional customer support: Our dedicated team provides comprehensive technical support and assistance throughout the entire process.

* Competitive pricing: We offer competitive pricing without compromising on quality or performance.

Choosing the Right UV Curing System: Factors to Consider

Selecting the appropriate UV curing system depends on various factors, including production volume, substrate type, ink or coating properties, and desired curing speed. Consult with our experts at Vtech Co., Ltd WT to determine the optimal system for your specific needs. We will guide you through the selection process, considering your application and budget to ensure you invest in the most suitable UV curing equipment. Our goal is to empower you with the most efficient and effective solution for your operations.

Frequently Asked Questions (FAQ)

Q: What is the difference between UV and LED UV curing systems?

A: LED UV systems consume less energy and generate less heat compared to traditional UV systems using mercury-vapor lamps. They also offer longer lamp life and are more environmentally friendly.

Q: How long do UV lamps last?

A: The lifespan of UV lamps varies depending on usage intensity and the type of lamp. However, LED UV lamps generally offer a significantly longer lifespan than traditional mercury-vapor lamps.

Q: Are UV curing systems safe to use?

A: UV curing systems can emit UV light, which can be harmful to the eyes and skin. Appropriate safety measures, including the use of protective eyewear and clothing, are essential during operation.

Q: What type of maintenance do UV curing systems require?

A: Regular maintenance includes lamp replacement, cleaning of the system, and checking for any mechanical issues. Consult our comprehensive maintenance guide for specifics.

Q: What are the environmental implications of UV curing?

A: While UV curing offers several environmental benefits, such as reduced energy consumption and VOC emissions compared to traditional thermal curing methods, proper disposal of lamps at the end of their lifespan is crucial. Consult local regulations for proper disposal procedures.

Q: Can I use any type of ink or coating with a UV curing system?

A: No, only specifically formulated UV-curable inks and coatings are compatible with UV curing systems. Consult with your ink and coating supplier or our experts at Vtech Co., Ltd WT to ensure compatibility.

Q: What is the cost of a UV curing system?

A: The cost of a UV curing system varies significantly depending on the system's size, features, and specific requirements. Contact us for a customized quote based on your needs.

Q: What is the warranty on Vtech Co., Ltd WT UV curing systems?

A: We offer a comprehensive warranty on all our UV curing systems. Specific details are available in the warranty document provided upon purchase. Our commitment to quality ensures long-term reliable performance.

Q: Do you offer training on how to operate and maintain UV curing systems?

A: Yes, we provide comprehensive training on the operation and maintenance of our UV curing systems to ensure our customers can effectively utilize the equipment.

Q: What are the typical turnaround times for orders?

A: Turnaround times vary depending on the specific system and current order volume, but we strive to provide timely delivery. Contact us for an estimated delivery date once you place your order. We are dedicated to efficient order processing and timely delivery.

Conclusion: Partner with Vtech Co., Ltd WT for Superior UV Curing Solutions

Vtech Co., Ltd WT has established itself as a trusted provider of high-quality UV and LED UV curing systems, serving diverse industries for over a decade. Our commitment to innovation, customer satisfaction, and technological excellence ensures that we provide superior solutions to meet your specific needs. Contact us today to explore how our advanced UV curing systems can enhance your production efficiency, product quality, and overall profitability. Let Vtech Co., Ltd WT be your partner in achieving optimal UV curing solutions.

Everything You Need to Know About uv curing system

The Ultimate Guide to LED UV Curing Systems for Printing

Everything You Need to Know About uv curing unit

Advancements in LED UV Curing Systems for Printing

normal

What's the cooling way?

What is the major advantages of UV LED curing system’s than other UV curing system?

Can you do a design for me or company?

How to proceed an order for UV LED curing system?

How about the after service?

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Offset LED pre-press testing machine

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang