The Ultimate Guide to UV Ink Curing Systems: A Complete Overview and Benefits

1. Introduction to UV Ink Curing Systems

In this section, we will provide a brief overview of UV ink curing systems, their purpose, and their main benefits. We will explain how UV ink curing systems work and the advantages they offer over traditional curing methods.

2. Benefits of UV Ink Curing Systems

Here, we will delve deeper into the numerous benefits of using UV ink curing systems, including faster curing times, improved print quality, enhanced durability, and environmental sustainability. We will also discuss how Vtech Co., Ltd's water-cooled UV and LED curing systems offer unique advantages for various printing applications.

• Faster Curing Times

This sub will highlight how UV ink curing systems can significantly reduce curing times compared to conventional methods, leading to increased productivity and shorter turnaround times.

• Enhanced Print Quality

We will discuss how UV ink curing systems can improve the overall print quality, including sharper image definition, vibrant colors, and precise registration, resulting in better output for printing projects.

• Environmental Sustainability

This sub will address the eco-friendly benefits of UV ink curing systems, such as lower energy consumption, reduced emissions, and less waste, aligning with Vtech Co., Ltd's commitment to sustainable production solutions.

3. Applications of UV Ink Curing Systems

In this section, we will explore the diverse applications of UV ink curing systems across various printing processes, such as offset press, gravure press, flexo press, coatings, and silk screen print. We will highlight the versatility and adaptability of Vtech Co., Ltd's UV and LED curing systems for different printing needs.

• Offset Press

This sub will focus on how UV ink curing systems can benefit offset press operations, including faster drying times, improved print quality, and increased efficiency, with a spotlight on Vtech Co., Ltd's innovative solutions.

• Silk Screen Print

We will discuss how UV ink curing systems are well-suited for silk screen printing, offering advantages such as better adhesion, reduced ink consumption, and enhanced color consistency, showcasing the capabilities of Vtech Co., Ltd's curing systems in this area.

4. Vtech Co., Ltd's Water-Cooled UV and LED Curing Systems

This section will provide an in-depth overview of Vtech Co., Ltd's exceptional water-cooled UV and LED curing systems, highlighting their advanced technology, reliable service, and efficient production. We will showcase how these systems are designed to meet the evolving needs of the printing industry.

• Advanced Technology

We will spotlight the cutting-edge technology utilized in Vtech Co., Ltd's water-cooled UV and LED curing systems, emphasizing their precision, reliability, and performance, demonstrating the company's dedication to innovation.

• Reliable Service and Efficient Production

Here, we will focus on Vtech Co., Ltd's commitment to providing reliable service and efficient production solutions with their UV and LED curing systems, emphasizing their rich experience, expertise, and patented technologies in the industry.

Conclusion:

In conclusion, UV ink curing systems offer a revolutionary approach to printing processes, delivering a host of benefits and applications across various industries. Vtech Co., Ltd's water-cooled UV and LED curing systems stand out as reliable and efficient solutions, setting new standards in the field of UV printing technology.

FAQs:

1. What are the main advantages of using UV ink curing systems?

UV ink curing systems offer faster curing times, improved print quality, enhanced durability, and environmental sustainability, making them a preferred choice for various printing applications.

2. How can UV ink curing systems benefit offset press operations?

UV ink curing systems can bring significant advantages to offset press operations, including faster drying times, enhanced print quality, and increased efficiency.

3. What makes Vtech Co., Ltd's water-cooled UV and LED curing systems unique?

Vtech Co., Ltd's curing systems are distinguished by their advanced technology, reliable service, and efficient production capabilities, providing exceptional solutions for the printing industry.

4. What are the key applications of UV ink curing systems?

UV ink curing systems find applications in offset press, gravure press, flexo press, coatings, and silk screen print, offering versatile solutions for a wide range of printing needs.

5. How do UV ink curing systems contribute to environmental sustainability?

UV ink curing systems consume less energy, produce minimal emissions, and reduce waste, aligning with eco-friendly practices and sustainability goals in the printing industry.

The Ultimate Guide to UV Lamp Curing Systems: Everything You Need to Know

Cutting-Edge UV Curing Solutions for Efficient Production

What is uv conveyor curing

The Power of UV Light for Paint Curing

normal

What materials can UV printers print?

Why choose Vtech's UV LED curing machine?

Where is your factory located?

lf the light intensity is adjustable?

how can we guarantee quality?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

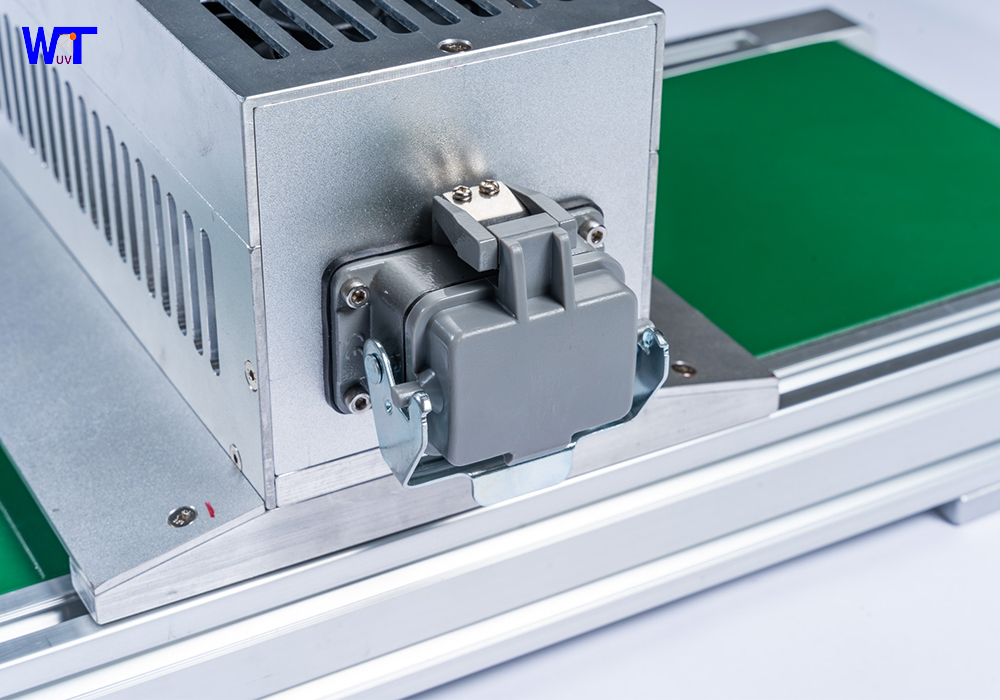

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang