How WT's LED UV Curing System Can Revolutionize Your Manufacturing Process

Revolutionizing Manufacturing with WT's LED UV Curing System

In today's fast-paced manufacturing industry, efficiency, productivity, and quality are of utmost importance. This is where WT's LED UV curing system comes into play, offering a revolutionary and effective solution for curing various materials in a wide range of manufacturing processes. we will explore the key benefits and features of WT's LED UV curing system and how it can positively impact your manufacturing operations.

What is a LED UV Curing System?

LED UV curing systems are advanced technology solutions designed to cure inks, coatings, adhesives, and other materials using energy-efficient UV LED lamps. These systems eliminate the need for traditional mercury-based UV lamps, offering a more sustainable and cost-effective curing solution. WT has been a leading innovator in LED UV curing technology, providing cutting-edge systems for various industrial applications.

The Benefits of Using WT's LED UV Curing System

1. Energy Efficiency: WT's LED UV curing system is designed to consume significantly less energy compared to traditional UV curing systems. This results in reduced operating costs and a more environmentally friendly manufacturing process.

2. Fast Curing: With WT's LED UV curing system, manufacturers can achieve faster curing times, leading to improved production throughput and reduced lead times. This ultimately enhances overall productivity and efficiency.

3. Enhanced Quality: The precise control and consistent output of WT's LED UV curing system ensure high-quality curing results, with minimal heat exposure and reduced risk of material damage. This leads to improved product quality and reliability.

4. Versatility: WT's LED UV curing system can be tailored to suit specific manufacturing requirements, offering flexibility in curing various substrates and materials. This adaptability makes it an ideal solution for diverse manufacturing applications.

5. Longevity and Reliability: LED UV lamps in WT's curing system have a longer lifespan compared to traditional UV lamps, reducing maintenance requirements and downtime, and ensuring consistent performance over time.

Applications of WT's LED UV Curing System

WT's LED UV curing system finds applications in various manufacturing sectors, including but not limited to:

- Printing and Packaging: Achieve high-speed curing for printing inks, varnishes, and coatings in the packaging and commercial printing industry.

- Electronics: Precise and safe curing solutions for sensitive electronic components and assemblies.

- Automotive: Efficient curing of adhesives, paints, and protective coatings in automotive manufacturing processes.

- Medical Devices: Sterilization and bonding applications for medical device manufacturing.

- Wood and Furniture: Fast and reliable curing for wood coatings and finishes in the furniture industry.

Conclusion

In conclusion, WT's LED UV curing system offers a game-changing solution for manufacturers seeking to optimize their curing processes. With its energy-efficient, fast, and reliable performance, this advanced technology can significantly improve productivity, quality, and sustainability in manufacturing operations across various industries.

FAQs

1. How does WT's LED UV curing system differ from traditional UV curing systems?

WT's LED UV curing system offers energy-efficient and fast curing solutions compared to traditional UV systems, resulting in reduced operating costs and improved productivity.

2. What are the key advantages of using WT's LED UV curing system?

The key advantages include energy efficiency, fast curing, enhanced quality, versatility, and longevity and reliability.

3. What are the main applications of WT's LED UV curing system?

WT's LED UV curing system finds applications in printing and packaging, electronics, automotive, medical devices, and wood and furniture industries, among others.

4. How can WT's LED UV curing system benefit my manufacturing processes?

WT's LED UV curing system offers increased productivity, higher quality, and reduced operating costs, making it an ideal solution for optimizing manufacturing operations.

The Ultimate Guide to UV Curing Lamps for Efficient Production

Ultraviolet Light Curing: A Complete Guide to WT's Innovative Technology

What is uv curing systems for printing

OEM/ODM ushio uv curing system Manufacturers and supplier

normal

What should I do when I don’t really know how to setting the printer parameters?

What is the major advantages of UV LED curing system’s than other UV curing system?

How to proceed an order for UV LED curing system?

lf the light intensity is adjustable?

Can we visit the factory?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

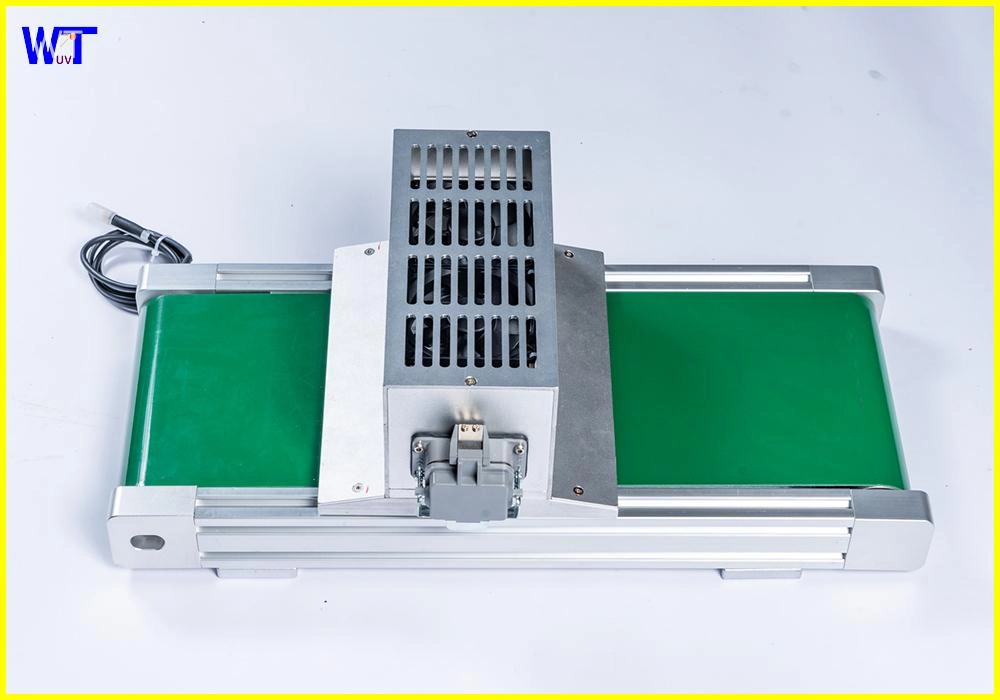

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang