WT UV Curing Solution for Flexo Printing

WT UV Curing Solution For Flexo Printing Machine

Unlock Peak Performance in Flexo Printing with WT UV Curing Solutions

Revolutionize your flexographic printing operations with the cutting-edge WT UV Curing Solution, proudly brought to you by Vtech Co., Ltd. For over 18 years, Vtech has specialized in advanced UV and LED curing systems, holding numerous patents and a reputation for unmatched reliability and efficiency. The WT solution is engineered to meet the dynamic demands of modern flexo printing, ensuring your output is not just fast, but flawless.

Why WT UV Curing is Essential for Your Flexo Press:

- Instant Drying, Enhanced Speed: Say goodbye to long drying times. WT UV Curing technology cures inks and coatings instantly, allowing for immediate post-press processing and significantly boosting your production speed and throughput.

- Superior Print Quality & Vibrancy: Achieve sharper images, finer details, and more vivid, consistent colors. Our advanced systems lock in ink pigments, preventing dot gain and ensuring every print stands out with exceptional clarity.

- high quality Durability: WT-cured prints offer superior resistance to scratches, chemicals, and fading. This enhanced durability means your products maintain their quality and appearance longer, adding value for your clients.

- Boosted Efficiency & Cost Savings: By eliminating the need for drying tunnels and reducing energy consumption (especially with our LED UV options), WT solutions lower operational costs. Faster turnaround times also mean you can take on more jobs, increasing profitability.

- Reliability Backed by Expertise: As a Vtech product, the WT UV Curing Solution benefits from years of dedicated research, development, and real-world application across various printing industries. Our patented systems are built for consistent, trouble-free performance.

Invest in the WT UV Curing Solution for your Flexo Printing Machine and transform your production. Experience the Vtech difference – where innovation meets reliability, and every print is a testament to quality.

Ready to elevate your flexo printing? Contact us today to learn more about how WT UV Curing can optimize your operations.

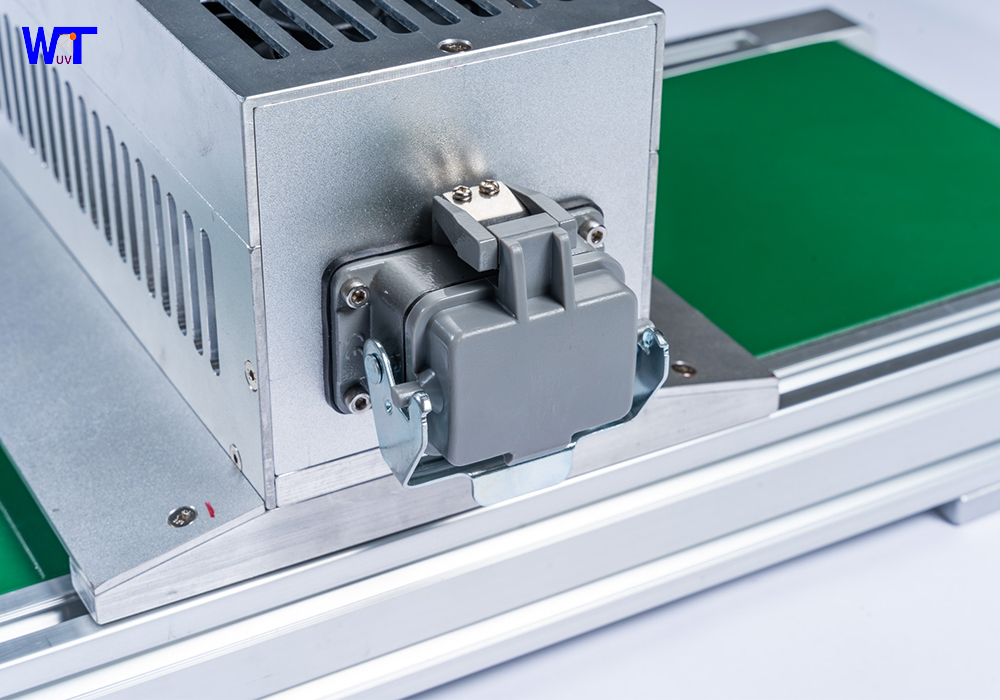

Product Image

Advantages

24 Hours Service Hotline: All our team of service are fully conversant with our extensive range of products and can quickly and expertly talk you through any question you may ask. Vtech is committed to provide a 24 hours customer service/breakdown hotline in local office.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

The operation interface is simple, the sound and light alarm corresponds to the light source module, and the fault can be quickly determined.

FAQ

Are you a trader or manufacturer?

lf the light intensity is adjustable?

How to cooperate with you and what is the cooperation process?

What should I do when I don’t really know how to setting the printer parameters?

Customized conveyor belt type UV LED curing equipment

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang