WT Compact UV Curing System: High Efficiency in a Small Footprint

WT Compact UV Curing System: High Efficiency in a Small Footprint

Are you looking to revolutionize your production process with advanced curing technology that fits your space and budget? The WT Compact UV Curing System from Vtech Co., Ltd. is your solution. Designed for peak performance in a streamlined package, this system brings cutting-edge UV technology directly to your operations, ensuring faster turnaround times, superior finish quality, and significant energy savings.

At Vtech, established in 2006, we specialize in UV and LED UV curing systems, backed by numerous industry patents and extensive experience. Our WT Compact UV Curing System embodies our commitment to innovation and reliability, delivering the efficiency you need to stay ahead.

Unlock Unmatched Performance with WT

Compact Design, Powerful Results

Don't let limited space hinder your productivity. The WT Compact UV Curing System is engineered with a minimal footprint, allowing for seamless integration into existing production lines without extensive modifications. Despite its size, it delivers robust curing power, ensuring consistent, high-quality results every time.

Speed and Efficiency Redefined

Experience rapid curing that dramatically accelerates your production cycles. Our system ensures instant drying, reducing bottlenecks and enabling immediate post-processing. This translates to increased throughput, lower operational costs, and a quicker return on your investment.

Built for Reliability

Vtech's legacy of excellence means you get a system designed for durability and long-term performance. The WT Compact UV Curing System features robust construction and reliable components, minimizing downtime and maximizing your uptime. We understand the critical nature of your operations, and our technology is built to perform consistently, day after day.

Versatility Across Applications

Whether you're in offset press, gravure press, flexo press, coatings, or silk screen printing, the WT Compact UV Curing System adapts to your specific needs. Its versatile capabilities make it an indispensable tool for a wide range of industrial applications, providing perfect cures for inks, coatings, and adhesives.

Simplified Operation

We believe advanced technology should be easy to use. The WT Compact UV Curing System features intuitive controls and straightforward maintenance, allowing your team to operate it effectively with minimal training. Focus on production, not complex setup.

Why Choose Vtech and WT?

With years of expertise and a strong portfolio of patents, Vtech Co., Ltd is a trusted leader in UV curing technology. We don't just sell equipment; we provide solutions backed by deep industry knowledge and dedicated support. Choosing the WT Compact UV Curing System means partnering with a company committed to your success, offering reliable service and efficient production tools designed to elevate your business.

Embrace the future of curing technology with the WT Compact UV Curing System – where small size meets monumental performance.

Product Image

Advantages

We have over 17 years experience in UV curing industry.

Compact size, making it easy to integrate into fully automated production lines and equipment.

With line disconnection alarm and LED dead point detection alarm function.

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

FAQ

how can we guarantee quality?

Where is your factory located?

lf the light intensity is adjustable?

Why and how do I replace a UV led?

If you have any questions or concern, please contact us.

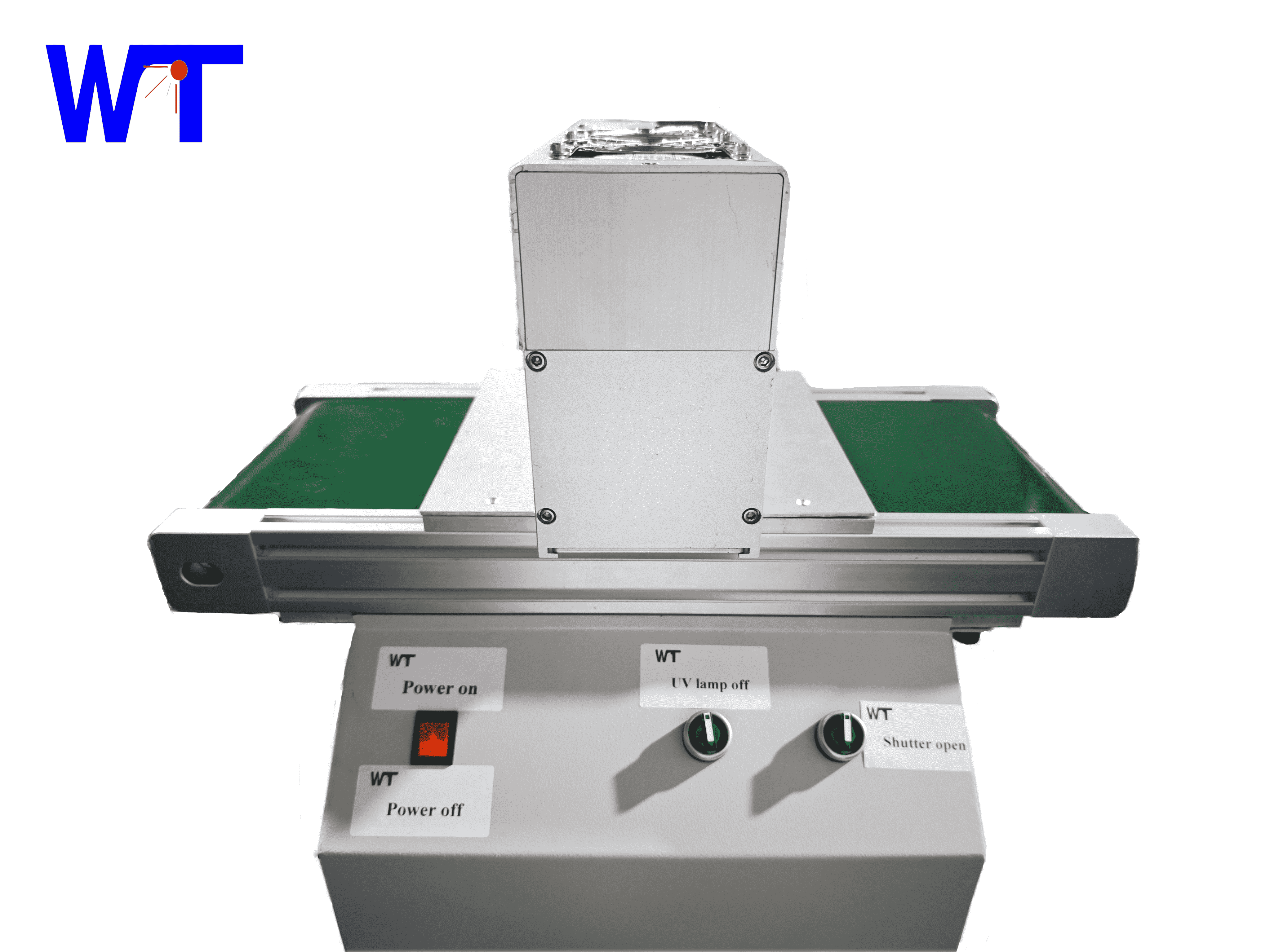

Small UV drying machine

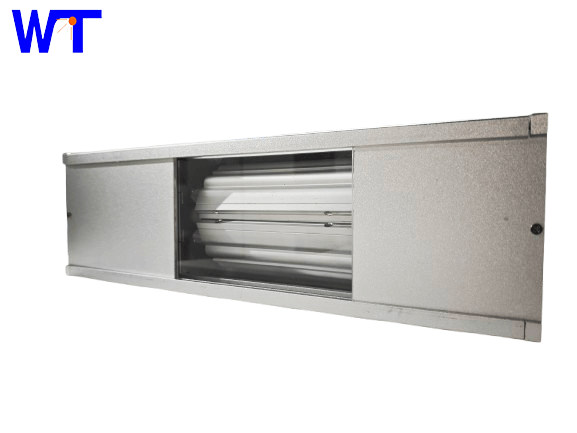

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

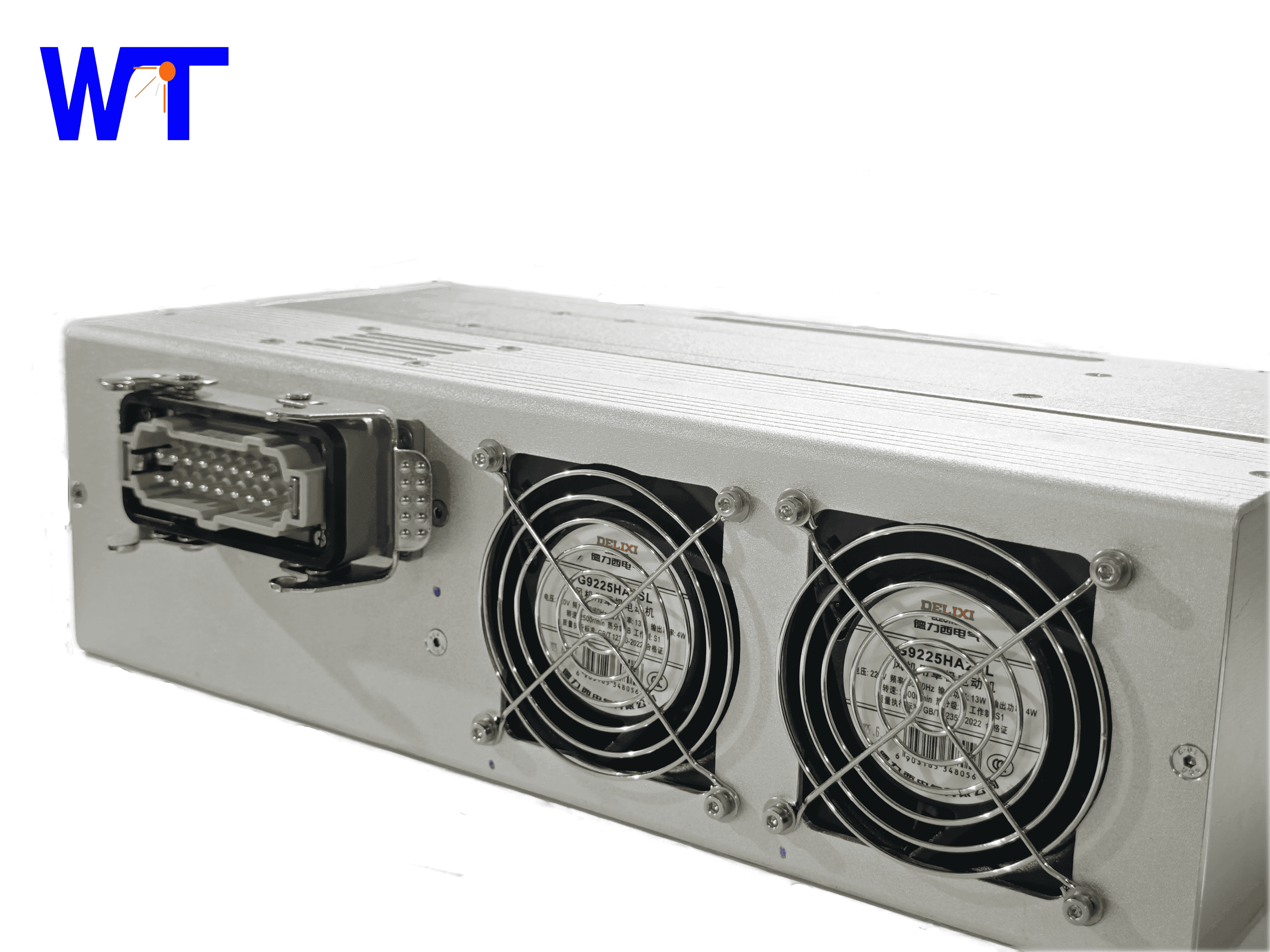

Customized conveyor belt type UV LED curing equipment

Offset LED pre-press testing machine

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang