WT CIPP UV Curing System: Revolutionizing Pipe Rehabilitation for Modern Infrastructure

Discover the WT CIPP UV Curing System: The Future of Pipe Rehabilitation

Tired of slow, disruptive pipe repair methods? The WT CIPP UV Curing System, brought to you by Vtech Co., Ltd, is engineered to transform how you approach infrastructure maintenance. Leveraging advanced UV technology, our system provides a trenchless, rapid, and incredibly durable solution for rehabilitating aging or damaged pipes, minimizing downtime and maximizing efficiency.

Vtech Co., Ltd, established in 2006, is a recognized leader in UV curing technology, holding numerous patents and a reputation for innovation. With extensive experience in developing high-performance UV and LED curing systems for diverse applications like offset, gravure, flexo press, coatings, and silk screen print, we bring that same commitment to excellence and reliability to the CIPP industry.

Unmatched Speed and Efficiency for Your Projects

Time is money, especially in infrastructure. Our WT CIPP UV Curing System significantly reduces project timelines compared to traditional methods. By utilizing powerful UV light, liners are cured in minutes rather than hours or days, allowing you to complete more projects faster, reduce labor costs, and restore services quicker to communities. This rapid curing process means less disruption for residents and businesses, boosting your project throughput.

Superior Durability and Long-Term Performance

The WT system doesn't just offer speed; it delivers strength. The UV-cured liners create a new, structural pipe within the existing one, boasting exceptional resistance to corrosion, abrasion, and chemicals. This results in a long-lasting, robust solution that enhances the integrity and lifespan of your pipe network. Trust in WT for rehabilitation that stands the test of time, significantly reducing future maintenance needs.

Minimal Disruption, Maximum Value

Say goodbye to extensive excavations and prolonged site disturbances. Our trenchless CIPP UV curing technology means fewer open trenches, less traffic disruption, and a smaller environmental footprint. This approach not only saves significant costs associated with digging and backfilling but also makes your projects more community-friendly, reflecting positively on your operations and delivering greater overall value.

Backed by Vtech’s Expertise and Innovation

When you choose the WT CIPP UV Curing System, you're partnering with Vtech Co., Ltd – a company synonymous with quality and innovation in UV technology. Our dedicated research and development, backed by years of industry experience and proprietary patents, ensures that you receive a reliable, cutting-edge system designed for peak performance and supported by expert knowledge. We understand your needs for efficient and dependable solutions.

Invest in the WT CIPP UV Curing System today and experience the next generation of pipe rehabilitation – faster, stronger, and smarter.

Detailed display

Our Advantages

Compact size, making it easy to integrate into fully automated production lines and equipment.

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

With stepless dimming function;

1. The conveyor speed can adjustment according to the products drying condition;

Question you may concern

Where is your factory located?

What's the whole UV LED curing system including?

Can I use my own PLC and Electric cabinet?

Why choose Vtech's UV LED curing machine?

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

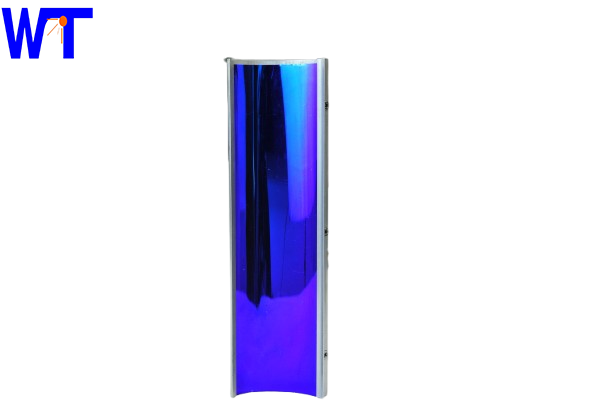

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang