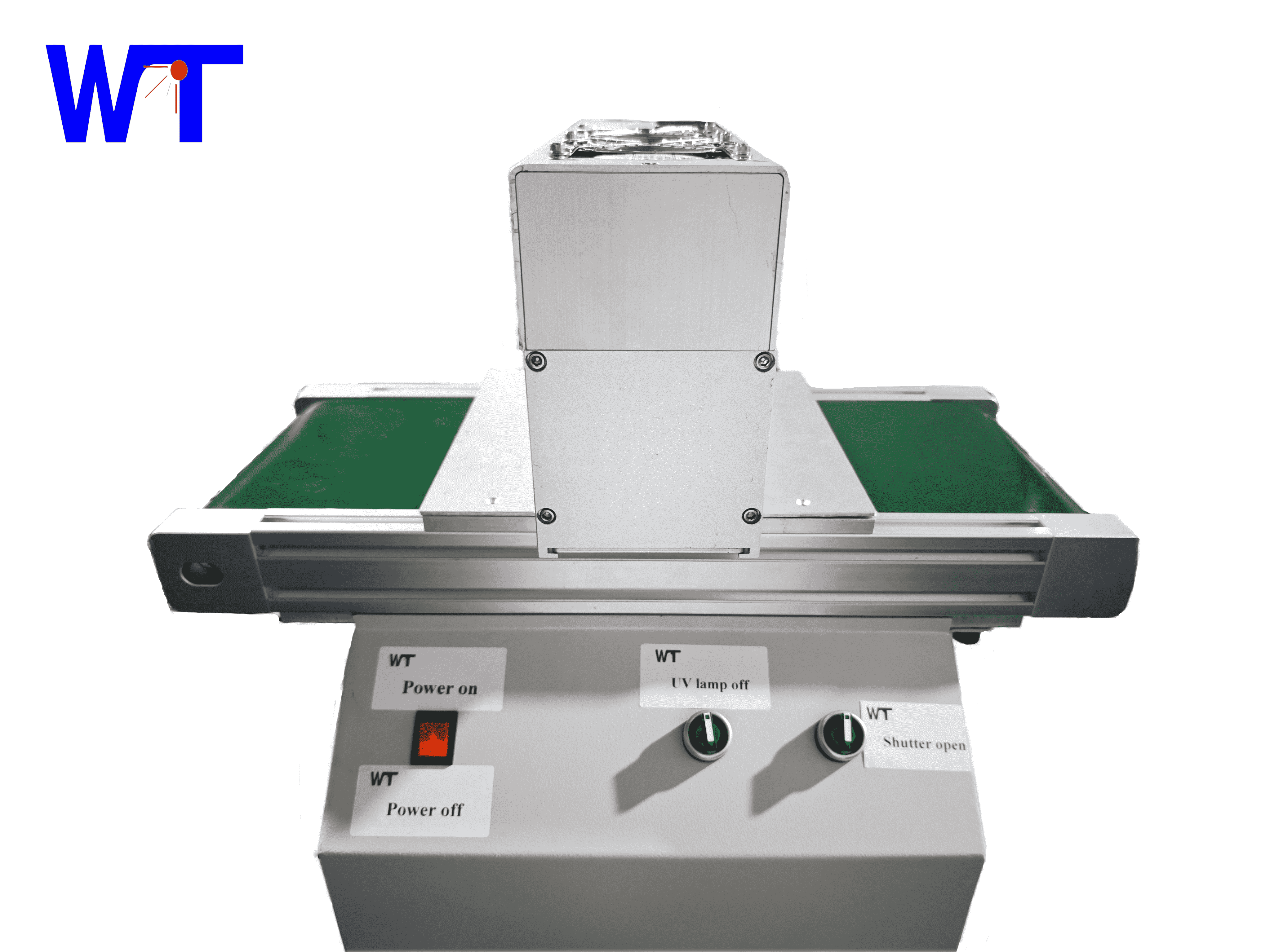

WT 395nm UV LED Curing System: Next-Gen Efficiency & Precision

Revolutionize Your Production with the WT 395nm UV LED Curing System

In today's fast-paced industrial landscape, efficiency, precision, and reliability are paramount. The WT 395nm UV LED Curing System, brought to you by Vtech Co., Ltd, is engineered to deliver exactly that. Since 2006, Vtech has been at the forefront of UV and LED curing technology, holding numerous patents and a reputation for excellence. Our WT system harnesses cutting-edge LED technology to provide a curing solution that not only meets but exceeds modern production demands.

Unmatched Performance & Sustainable Precision

Optimal 395nm Wavelength for Diverse Applications

The WT 395nm UV LED Curing System is precisely tuned to emit a wavelength optimized for rapid and thorough curing of a wide array of UV-curable inks, coatings, and adhesives. This ensures consistent, high-quality results across various substrates and processes, from intricate flexo prints to robust industrial coatings.

Energy Efficiency & Extended Longevity

Experience significant operational cost savings with our advanced LED technology. Unlike traditional UV lamps, the WT system offers instant on/off capabilities, minimal heat generation, and dramatically reduced power consumption. This not only lowers your energy bills but also extends the operational lifespan of the system, minimizing maintenance and maximizing uptime. Say goodbye to warm-up times and costly bulb replacements.

Consistent & Reliable Curing for Superior Results

Backed by Vtech's nearly two decades of specialized R&D and expertise, the WT 395nm system guarantees consistent and reliable curing performance. Our patented technology ensures uniform light distribution and stable output, translating into impeccable print quality, durable coatings, and secure adhesive bonds, every single time.

WT: Engineered for Your Industry with the Vtech Advantage

Versatility Across Industrial Applications

The WT 395nm UV LED Curing System is designed for seamless integration into a multitude of industrial processes. Whether you operate an offset press, gravure press, flexo press, or engage in silk screen printing or specialized coating applications, our system provides the robust, efficient curing power you need to enhance productivity and finish quality.

The Vtech Advantage: Innovation, Experience, and Trust

As Vtech Co., Ltd, we pride ourselves on being an enterprise specializing in advanced UV and LED curing systems. Our commitment to research, development, and production has resulted in many industry patents. With rich experience and deep expertise, we offer reliable service and solutions tailored to provide you with efficient and superior production outcomes.

Experience the Future of Curing with WT

Invest in the WT 395nm UV LED Curing System today and elevate your production capabilities. Achieve faster turnaround times, reduce operational costs, and produce higher-quality results with a system built on innovation, efficiency, and Vtech's trusted expertise. Contact us to discover how WT can transform your curing process.

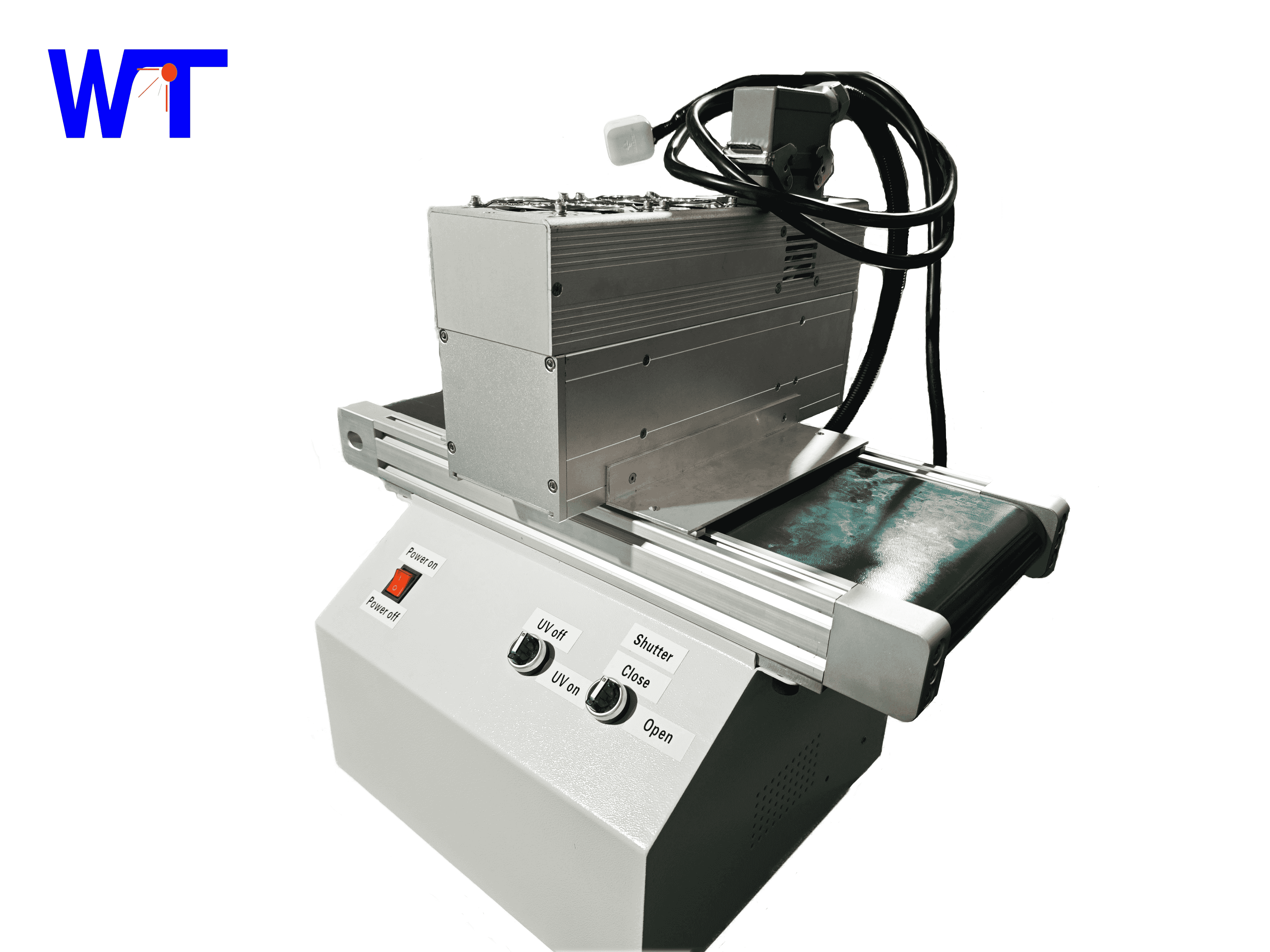

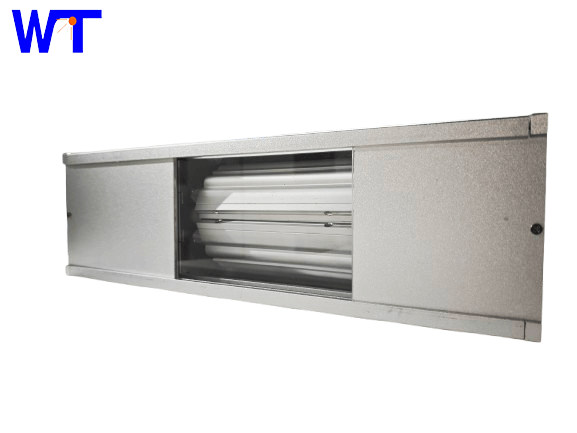

Detailed display

Our Advantages

1. The conveyor speed can adjustment according to the products drying condition;

Compact size, making it easy to integrate into fully automated production lines and equipment.

The operation interface is simple, the sound and light alarm corresponds to the light source module, and the fault can be quickly determined.

With stepless dimming function;

Question you may concern

Which wavelength do I need?

Can we visit the factory?

What materials can UV printers print?

What's the Peak Irradiance do I need?

Small UV drying machine

Customized conveyor belt type UV LED curing equipment

Water-cooled LED curing equipment

Offset LED pre-press testing machine

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang