Unlocking the Power of UV Cure Adhesive: How It Works and Benefits for Your Business

How Does UV Cure Adhesive Work?

we will explore the intriguing world of UV cure adhesive and uncover the science behind this groundbreaking technology. Join us as we delve into the inner workings of UV cure adhesive and its remarkable benefits for various industries.

Understanding UV Cure Adhesive

UV cure adhesive is a type of adhesive that cures or hardens when exposed to ultraviolet (UV) light. This process, known as photopolymerization, involves the use of UV light to initiate a chemical reaction that transforms the liquid adhesive into a solid, durable material. The result is a fast and efficient bonding solution that offers superior strength and performance.

The Mechanism Behind UV Cure Adhesive

The key to the success of UV cure adhesive lies in its photoinitiators, which are compounds that activate the curing process when exposed to UV light. When the adhesive is applied, the photoinitiators react to the UV light, causing the molecules in the adhesive to crosslink and form a strong bond. This process occurs within seconds, making UV cure adhesive an ideal choice for high-speed production environments.

Advantages of UV Cure Adhesive

One of the main advantages of UV cure adhesive is its rapid curing time. Unlike traditional adhesives that require extended drying or curing periods, UV cure adhesive sets almost instantly, allowing for accelerated production schedules and increased efficiency. Additionally, UV cure adhesive offers excellent adhesion to a wide range of substrates, including plastics, metals, glass, and composites, making it a versatile solution for diverse applications.

Applications of UV Cure Adhesive

The versatility of UV cure adhesive lends itself to a multitude of applications across various industries. From automotive and electronics to medical devices and packaging, UV cure adhesive is used to bond components, seal assemblies, and enhance product performance. Its ability to deliver reliable and durable bonds in challenging environments makes UV cure adhesive an invaluable asset for manufacturers seeking to elevate their product quality.

Choosing the Right UV Cure Adhesive System

When considering UV cure adhesive for your production needs, it is essential to partner with a reputable manufacturer like Vtech Co., Ltd. With over a decade of experience in developing and producing water-cooled and LED UV curing systems, Vtech Co., Ltd offers a range of innovative solutions tailored to different printing and coating applications. Their expertise and patented technologies ensure reliable service and efficient production for your business.

In conclusion, the transformative power of UV cure adhesive is undeniable, offering unmatched speed, strength, and versatility for modern manufacturing. By harnessing the science behind UV cure adhesive, businesses can elevate their production capabilities and achieve superior results. Embrace the potential of UV cure adhesive and unlock new opportunities for your business with Vtech Co., Ltd.

Unique FAQs:

1. How does UV cure adhesive differ from traditional adhesives?

UV cure adhesive differs from traditional adhesives in its rapid curing process, which is activated by exposure to UV light. This results in faster production times and superior bond strength.

2. Can UV cure adhesive be used for bonding different materials?

Yes, UV cure adhesive offers excellent adhesion to a wide range of substrates, including plastics, metals, glass, and composites, making it a versatile solution for diverse applications.

3. What are the key benefits of using UV cure adhesive in manufacturing?

The key benefits of using UV cure adhesive in manufacturing include rapid curing times, superior bond strength, and enhanced product quality, leading to increased efficiency and cost savings.

4. Is UV cure adhesive environmentally friendly?

UV cure adhesive is considered environmentally friendly as it does not emit volatile organic compounds (VOCs) during the curing process, contributing to a healthier and safer work environment.

5. How can Vtech Co., Ltd assist with implementing UV cure adhesive systems?

Vtech Co., Ltd offers a range of UV curing systems tailored to different printing and coating applications, backed by rich experience and patented technologies to provide reliable service and efficient production for your business.

The Advantages of Using Ultraviolet Light Curing Systems in Printing Industry

OEM/ODM standar uv curing system Manufacturers and supplier

The Ultimate Guide to UV Paint Curing Lamps for Efficient Production

The Future of UV Cure Systems: Revolutionizing Industrial Coating Technology

normal

How to cooperate with you and what is the cooperation process?

how can we guarantee quality?

How to proceed an order for UV LED curing system?

Are you a trader or manufacturer?

Can we visit the factory?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

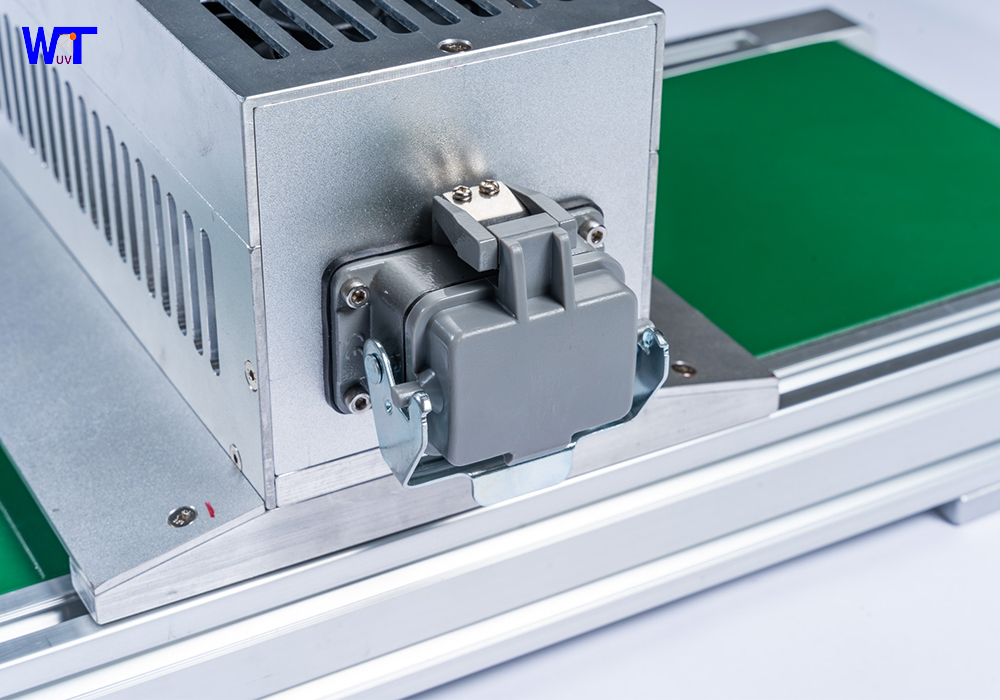

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang