The Ultimate Guide to LED UV Curing Systems by Vtech Co., Ltd

The Importance of LED UV Curing Systems in Modern Printing

In today's fast-paced and highly competitive printing industry, the need for efficient and reliable curing systems has never been greater. With the increasing demand for high-quality prints and fast turnaround times, traditional curing methods are no longer sufficient. This is where LED UV curing systems come into play, offering a game-changing solution that revolutionizes the printing process.

Understanding LED UV Curing Systems

LED UV curing systems utilize light-emitting diodes (LEDs) to cure inks, coatings, and adhesives instantly. Unlike traditional curing methods, such as thermal or solvent-based curing, LED UV curing offers numerous advantages, including energy efficiency, reduced maintenance costs, and enhanced performance. Vtech Co., Ltd, a leading enterprise specializing in UV curing systems, has taken this technology to the next level with their innovative water-cooled and LED UV curing systems.

The Benefits of LED UV Curing Systems

1. Improved Print Quality and Color Consistency

LED UV curing systems provide precise and uniform curing, resulting in sharper images, vibrant colors, and superior print quality. With Vtech Co., Ltd's advanced LED UV curing systems, printers can achieve consistent color reproduction and exceptional print clarity across various substrates.

2. Faster Production Speeds and Increased Productivity

By curing inks and coatings instantly, LED UV curing systems eliminate the need for drying time, allowing for faster production speeds and higher throughput. This results in increased productivity and shorter turnaround times, giving printers a competitive edge in the market.

3. Enhanced Environmental Sustainability

Compared to traditional curing methods, LED UV curing systems are more environmentally friendly, as they produce minimal heat and emit no ozone or volatile organic compounds (VOCs). Vtech Co., Ltd's LED UV curing systems are designed to meet the highest environmental standards, making them the ideal choice for eco-conscious printers.

The Versatility of LED UV Curing Systems

Vtech Co., Ltd's LED UV curing systems are designed to meet the diverse needs of the printing industry. Whether it's offset press, gravure press, flexo press, coatings, or silk screen print, their extensive range of UV and LED curing systems provides reliable service and efficient production. With numerous patents in the industry and a wealth of experience, Vtech Co., Ltd has established itself as a leader in the development and production of cutting-edge LED UV curing solutions.

Choosing the Right LED UV Curing System for Your Business

When selecting an LED UV curing system for your printing operation, it's essential to consider factors such as substrate compatibility, ink or coating type, and production volume. Vtech Co., Ltd's team of experts can provide valuable insights and guidance to help you choose the most suitable LED UV curing system for your specific needs, ensuring optimal performance and cost-effectiveness.

In conclusion, it's clear that LED UV curing systems have become indispensable in modern printing, offering a host of benefits that significantly improve print quality, production efficiency, and environmental sustainability. With Vtech Co., Ltd leading the way with their innovative LED UV curing solutions, printers can stay ahead of the competition and elevate their business to new heights.

FAQs

Q: Are LED UV curing systems energy-efficient?

A: Yes, LED UV curing systems are highly energy-efficient, consuming significantly less power than traditional curing methods.

Q: Can LED UV curing systems be used for different printing applications?

A: Absolutely. Vtech Co., Ltd's LED UV curing systems are versatile and suitable for a wide range of printing processes, including offset press, flexo press, coatings, and more.

Q: How does Vtech Co., Ltd ensure the reliability of their LED UV curing systems?

A: Vtech Co., Ltd leverages their extensive experience and expertise to design and produce LED UV curing systems that are robust, reliable, and backed by superior customer service.

Q: What sets Vtech Co., Ltd's LED UV curing systems apart from the competition?

A: Vtech Co., Ltd's LED UV curing systems stand out for their advanced technology, exceptional performance, and commitment to environmental sustainability.

Effective Use of Benchtop UV Curing System for Efficient Production

The Ultimate Guide to UV Flood Curing Systems | Vtech Co., Ltd

The Guide to Selecting the Best UV Curing Lamp for Your Printing Needs

UV Curing of 3D Ink Problems - Solutions by Vtech Co., Ltd WT

normal

Are you a trader or manufacturer?

How to proceed an order for UV LED curing system?

Can you do a design for me or company?

What's the whole UV LED curing system including?

When can I get the quotations?

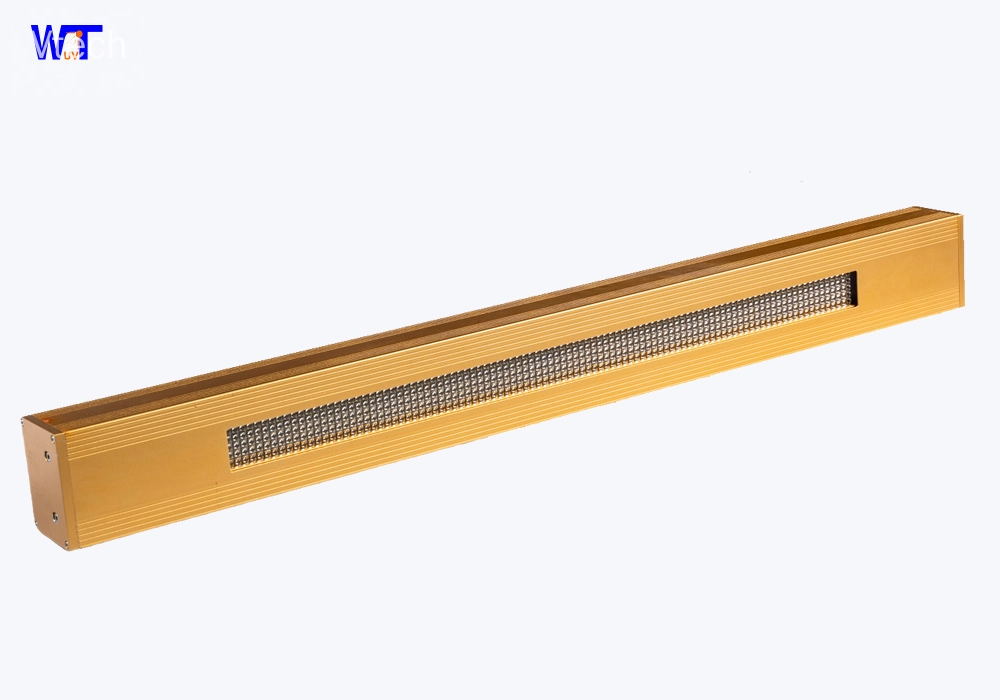

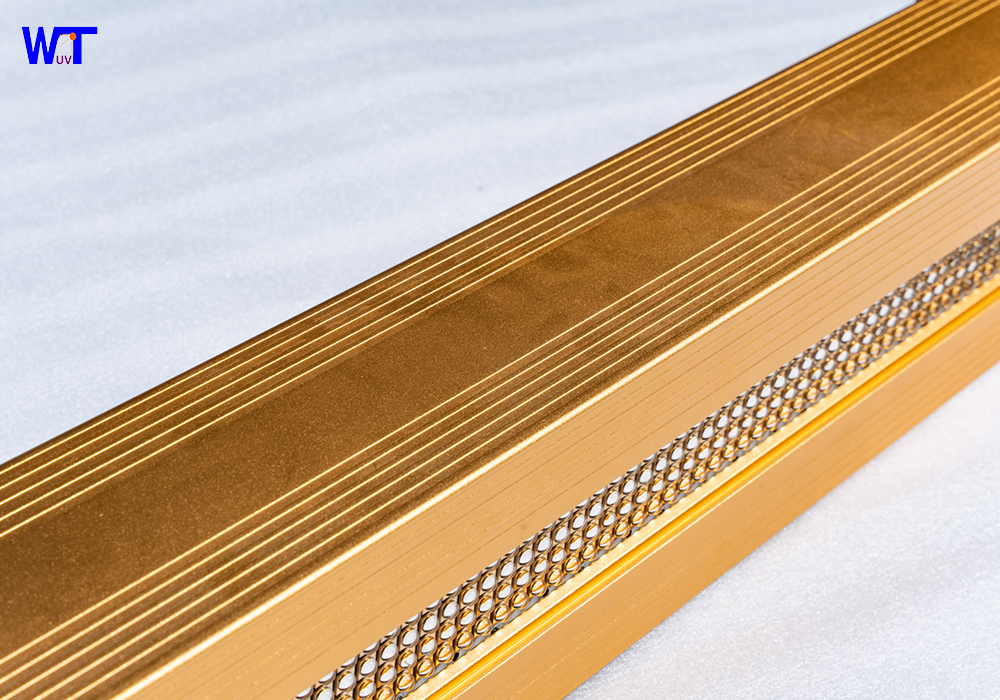

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang