Efficient WT UV Curing System LEDs for Precision & Reliability

Discover unparalleled precision and efficiency with the WT UV Curing System LEDs. Tailored for both industrial and artisanal applications, our cutting-edge curing system offers you the in reliability and performance. Harnessing the power of UV LED technology, WT provides a fast, consistent, and energy-efficient solution that ensures superior curing results every time.

Designed to bring your projects to life with exacting detail, our UV curing system uses the latest LED technology to increase productivity and lower operational costs. The advanced engineering of WT ensures consistent, uniform curing with minimal heat output, safeguarding your materials and reducing the risk of any potential damage.

The robust design of the WT UV Curing System LEDs provides unmatched durability, making it not only a dependable choice but also a future-proof investment. Easy to install and maintain, it integrates seamlessly into your existing workflows, ensuring a smooth transition without any operational hiccups.

Take advantage of WT's commitment to quality and performance. Each component of our UV curing system is meticulously crafted, delivering a higher degree of satisfaction and peace of mind. Experience the confidence that comes with using a product designed with professionalism and reliability at its core.

Invest in the WT UV Curing System LEDs today—where innovation meets tradition to deliver nothing less than excellence in UV curing.

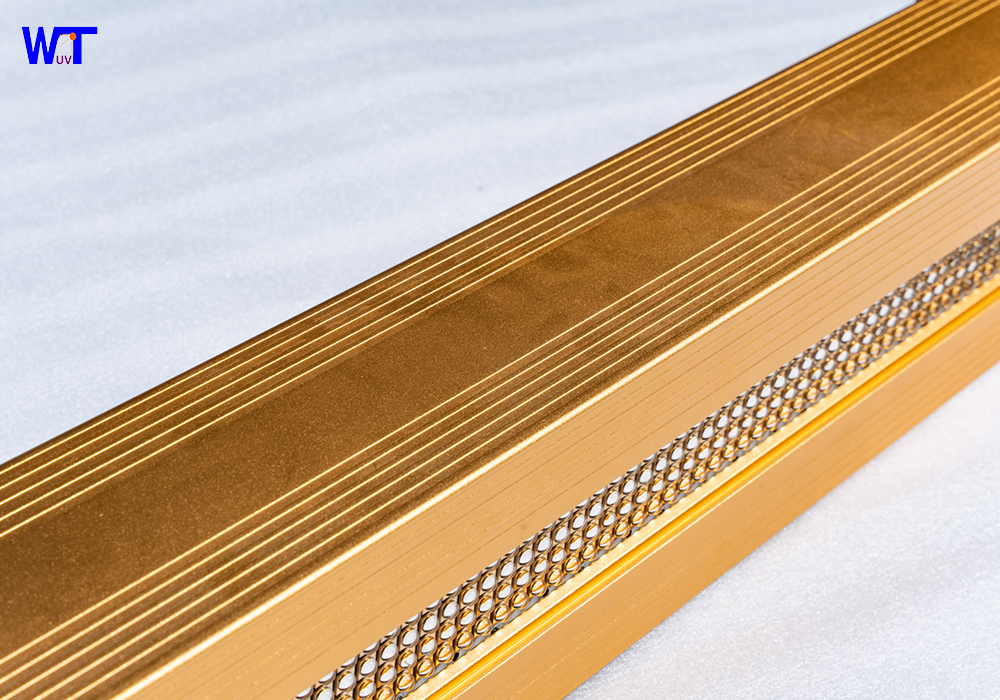

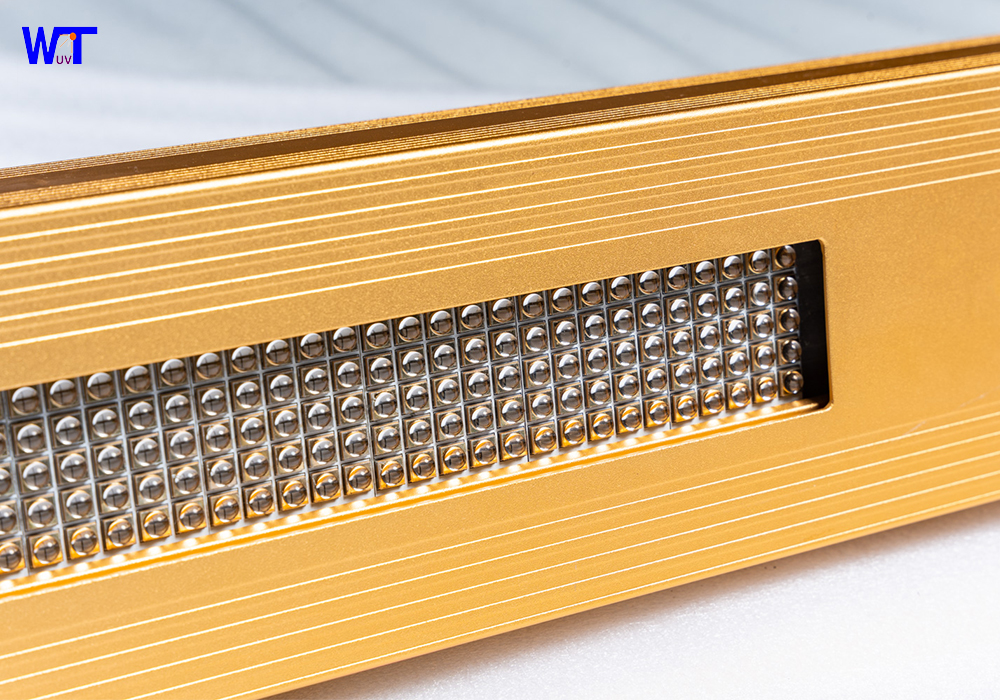

Detailed display

Advantages

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

UV energy uniformity ≥ 98%.

FAQ

How to cooperate with you and what is the cooperation process?

Why and how do I replace a UV led?

Can I use my own PLC and Electric cabinet?

How does your factory do the quality control?

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Offset LED pre-press testing machine

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang