What is automated uv curing system

- What is an Automated UV Curing System? WT

- Understanding the Fundamentals of UV Curing

- Automated UV Curing System: A Deep Dive into Automation

- Benefits of Choosing an Automated UV Curing System

- Increased Production Speed and Efficiency

- Improved Product Quality and Consistency

- Reduced Labor Costs and Increased Productivity

- Enhanced Safety and Reduced Environmental Impact

- Types of Automated UV Curing Systems Offered by Vtech Co., Ltd.

- Water-Cooled UV Curing Systems

- LED UV Curing Systems

- Applications of Automated UV Curing Systems Across Industries

- Offset Printing

- Gravure Printing

- Flexographic Printing

- Coatings

- Silk Screen Printing

- Choosing the Right Automated UV Curing System for Your Needs

- Production Volume and Speed

- Substrate Type and Material Properties

- Ink and Coating Compatibility

- Budget and ROI

- Frequently Asked Questions (FAQ)

- Conclusion: Elevate Your Printing and Coating Processes with Vtech Co., Ltd.

What is an Automated UV Curing System? WT

Understanding the Fundamentals of UV Curing

Ultraviolet (UV) curing is a rapid and efficient photopolymerization process that uses UV light to instantly harden specialized inks, coatings, and adhesives. Unlike traditional thermal curing methods, UV curing eliminates the need for extended drying times and high temperatures, leading to significant improvements in production speed and energy efficiency. This process is particularly beneficial for high-volume printing and coating applications. Choosing the right automated UV curing system significantly impacts your production line's overall efficiency and output.

Automated UV Curing System: A Deep Dive into Automation

An automated UV curing system integrates the UV curing process with automated machinery for precise and consistent curing. These systems typically incorporate conveyor belts, robotic arms, or other automated mechanisms to precisely move materials through the UV curing process. Automation eliminates manual handling, reducing human error, and ensures uniform curing across all materials. This automated approach enhances consistency, speeds up production significantly, and optimizes the overall quality of the final product. Investing in automated UV curing technology is an investment in the future of your business.

Benefits of Choosing an Automated UV Curing System

The advantages of an automated UV curing system extend far beyond simply speeding up the curing process. Consider these key benefits:

Increased Production Speed and Efficiency

Automated systems drastically reduce processing time compared to manual methods. The continuous, automated movement of materials through the UV curing process ensures consistent throughput, leading to higher production volumes in less time. This increased efficiency translates directly to improved profitability and competitive advantage. Maximize your output with our cutting-edge automated UV curing solutions.

Improved Product Quality and Consistency

Automated UV curing systems offer superior control over the curing parameters, resulting in consistently high-quality finishes. The precise control over UV exposure time and intensity ensures uniform curing, minimizing defects and inconsistencies. This enhanced consistency leads to improved product quality and reduced waste. Achieve superior results and consistent quality with our advanced automated UV curing technology.

Reduced Labor Costs and Increased Productivity

Automation reduces the need for manual labor, directly lowering labor costs and freeing up employees for other tasks. Automated systems operate consistently and efficiently, maximizing overall productivity and minimizing the risk of human error. This efficient workflow allows for greater output with fewer resources. Streamline your workflow and boost productivity with our reliable automated UV curing systems.

Enhanced Safety and Reduced Environmental Impact

Automated systems reduce the risk of workplace accidents associated with manual handling of materials. Moreover, UV curing itself is a more environmentally friendly process than traditional thermal curing, often consuming less energy and generating fewer harmful emissions. Improve your environmental profile and boost worker safety with our advanced systems.

Types of Automated UV Curing Systems Offered by Vtech Co., Ltd.

Vtech Co., Ltd offers a diverse range of automated UV curing systems tailored to meet specific industry requirements. Our portfolio includes:

Water-Cooled UV Curing Systems

These systems utilize water cooling to maintain optimal operating temperatures, ensuring consistent performance and prolonging the lifespan of the system's components. Water-cooled systems are particularly effective in high-volume production environments where continuous operation is essential. Our water-cooled systems offer superior reliability and longevity.

LED UV Curing Systems

LED UV curing systems offer a more energy-efficient and environmentally friendly alternative to traditional mercury-based UV lamps. LED systems typically produce less heat and have longer lifespans, leading to reduced operating costs and maintenance requirements. Experience the benefits of energy efficiency with our innovative LED UV curing systems.

Applications of Automated UV Curing Systems Across Industries

Vtech Co., Ltd. automated UV curing systems find widespread application across various industries:

Offset Printing

Automated UV curing systems are integrated into high-speed offset printing presses to rapidly cure UV inks, ensuring high-quality prints with vibrant colors and excellent durability. Achieve crisp, vibrant prints with superior durability using our offset printing UV curing solutions.

Gravure Printing

These systems are perfectly suited for high-speed gravure printing applications, providing consistent curing of inks and coatings across a wide range of substrates. Increase efficiency and product quality in your gravure printing processes with our advanced systems.

Flexographic Printing

In flexographic printing, automated UV curing systems ensure rapid and uniform curing of inks, resulting in high-quality prints with excellent adhesion and durability. Our flexographic printing solutions help you achieve impeccable results every time.

Coatings

Beyond printing, automated UV curing systems are increasingly used for curing coatings in various applications, from wood finishing to metal coatings. Achieve consistent, high-quality coatings across diverse substrates.

Silk Screen Printing

Automated UV curing enhances efficiency and quality in silk screen printing, creating vibrant and durable prints on a range of materials. Our systems are a perfect fit for demanding silk screen printing applications.

Choosing the Right Automated UV Curing System for Your Needs

Selecting the appropriate automated UV curing system involves carefully considering several factors:

Production Volume and Speed

The system's capacity should align with your production requirements to ensure efficient operation without bottlenecks. Our expert team can help you find the perfect fit for your production needs.

Substrate Type and Material Properties

Different materials require specific curing parameters. We offer tailored solutions to handle a wide range of substrates.

Ink and Coating Compatibility

Ensure compatibility between your inks and coatings and the chosen UV curing system. Our systems are engineered to work seamlessly with a wide variety of materials.

Budget and ROI

Consider the initial investment cost and the potential return on investment (ROI) based on increased production efficiency and reduced operating costs. Our experts can help you make the best financial decision.

Frequently Asked Questions (FAQ)

Q: What are the key differences between water-cooled and LED UV curing systems?

A: Water-cooled systems provide consistent performance in high-volume environments, while LED systems offer higher energy efficiency and longer lifespans.

Q: How can an automated UV curing system improve my production efficiency?

A: Automation eliminates manual handling, reduces processing time, and ensures consistent throughput, leading to higher production volumes and reduced labor costs.

Q: What industries benefit most from automated UV curing systems?

A: Offset printing, gravure printing, flexographic printing, coatings, and silk screen printing are among the industries significantly benefiting from this technology.

Q: What kind of maintenance is required for an automated UV curing system?

A: Regular maintenance, including lamp replacements and system cleaning, is recommended to ensure optimal performance and longevity. Our service team provides comprehensive support.

Q: How can I determine the right size UV curing system for my needs?

A: Contact our sales team. We’ll analyze your specific requirements and recommend the most suitable system for your production volume and material handling needs.

Q: What is the typical lifespan of a UV curing system?

A: The lifespan varies depending on usage and maintenance, but our systems are designed for long-term reliability. We offer extended warranty options for added peace of mind.

Q: Does Vtech offer installation and training services?

A: Yes, Vtech provides comprehensive installation and training services to ensure your team can operate the system efficiently and safely.

Q: What is the warranty period for Vtech’s automated UV curing systems?

A: The warranty period varies depending on the specific model; please contact our sales team for details.

Conclusion: Elevate Your Printing and Coating Processes with Vtech Co., Ltd.

Vtech Co., Ltd. is committed to providing cutting-edge automated UV curing systems that deliver superior performance, increased efficiency, and enhanced product quality. Our extensive experience and expertise in the UV curing industry, coupled with our commitment to innovation, ensure that we can meet the diverse needs of our clients. Contact us today to learn more about how our automated UV curing systems can transform your production processes.

How to Choose Right uv cure lights manufacturer and supplier ?

OEM/ODM led uv curing system Manufacturers and supplier

Ultraviolet Light Curing: A Complete Guide to WT's Innovative Technology

The Ultimate Guide to UV Curing Systems: Everything You Need to Know

normal

how can we guarantee quality?

How about the after service?

Can I use my own PLC and Electric cabinet?

How to proceed an order for UV LED curing system?

What's the cooling way?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

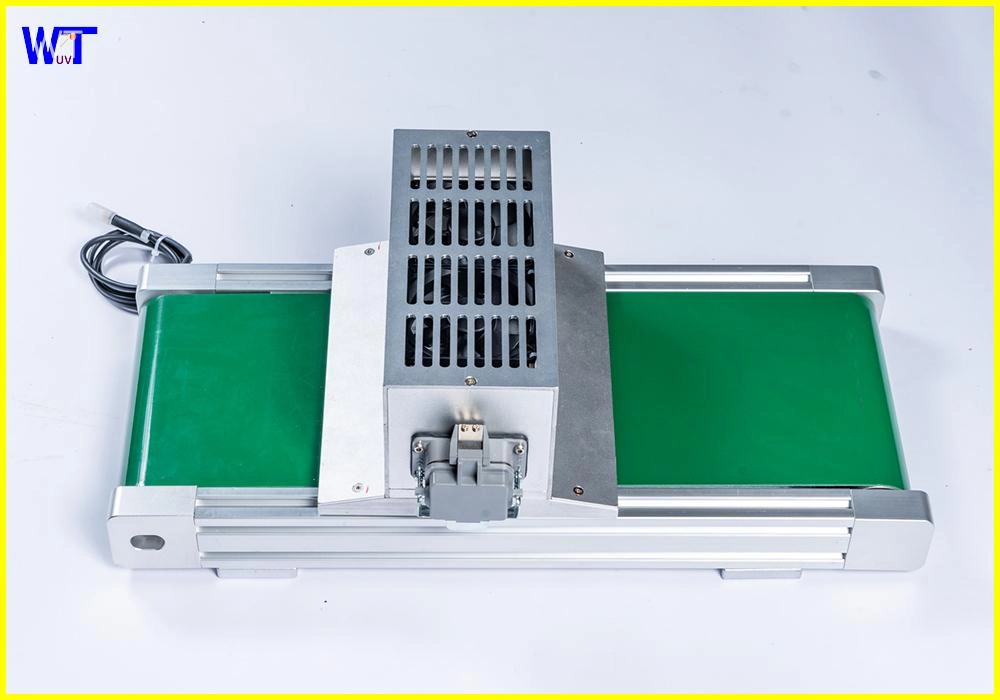

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang