How does UV technology make your product stand out?

The texture and visual effect of product packaging have always been important factors in attracting consumers. The UV polishing process, as an advanced printing processing technology, is widely used in various high-end packaging printing fields, and the UV process is constantly influencing printing worldwide

UV Printing Techniques: Enhancing Visual & Tactile Appeal

UV printing utilizes ultraviolet-curable materials applied to specific areas, creating unique visual effects and textures that significantly elevate product quality and perceived value. Below are key specialty UV techniques:

-

1、Localized Gloss UV

-

Process & Effect: Transparent UV varnish is applied to selected graphic areas. UV curing creates a high-gloss, raised effect with dimensional depth and a smooth finish, mimicking ceramics or porcelain.

-

Application: Highlights details and boosts visual impact.

-

Note: Unsuitable for rough, highly textured, or overly porous paper stocks.

-

2、Localized Wrinkle UV

-

Process & Effect: Special UV wrinkle ink is printed. Exposure to specific UV wavelengths causes the ink surface to shrink, forming unique fish-scale or creased textures resembling etched metal.

-

Application: Often combined with Gloss UV for striking visual and tactile contrast.

-

Note: Requires smooth paper surfaces (same as Gloss UV).

-

-

-

-

-

-

3、Matte UV

-

Process & Effect: Semi-transparent UV ink with special particles is printed, often over metallic substrates. Curing creates a textured, etched or sandblasted-like surface with a soft, white-toned matte appearance and fine sandpaper feel.

-

Application: Ideal for subtle, sophisticated designs with layered depth.

-

Note: Matte UV layers can be prone to wear/chipping. Durability and scratch resistance are enhanced by adding anti-abrasion additives to the UV ink.

-

-

-

-

-

-

-

4、Colored UV

-

Process & Effect: A transparent or tinted UV coating is applied over pre-printed colored graphics, intensifying gloss in those areas and creating visual depth through contrast with uncoated sections.

-

Application: Creates designs with contrast and visual tension.

-

Note: Paper requirements same as Gloss/Wrinkle UV.

-

5、Reverse UV

-

Process & Effect: Achieves stark contrast by printing a matte/satin base coat in specific areas, followed by a full-bleed high-gloss UV top coat (or vice-versa). Ink repellency creates distinct zones of high shine and dull/matte texture. Completed in one press pass, enabling diverse textures.

-

Application: Pinpoints visual focus; ideal for small cards, merchandise (e.g., badges, stickers), or designs needing bold contrast. Grain size adjustable via ink density and UV intensity.

-

Advantage: No post-processing; unique effects efficiently achieved.

-

-

-

-

Core Advantages & Future Outlook

UV printing is essential for premium packaging, offering rapid curing, high gloss, exceptional durability, and eco-friendliness (low VOCs), significantly enhancing user experience.

Key Future Trends:

-

Innovative Effects: Advanced light manipulation (e.g., gradients, dynamic textures) and sophisticated tactile finishes (refined or bold textures).

-

Eco-Advancements: Development of sustainable UV materials with lower VOCs and higher bio-based content.

-

Tech Integration: Seamless compatibility with digital printing for flexible, personalized UV applications.

-

Market Expansion: Moving beyond luxury packaging into mainstream markets like FMCG (Fast-Moving Consumer Goods) and electronics.

As technology matures and costs decrease, UV printing is poised for strong growth, driving the global "sensory upgrade" in packaging by continuously transforming product aesthetics and user interaction.

-

-

Paper Saved! Vtech.UV & EZ Gravteck Solve Printing Industry Cost Pain Point

Why Does Varnish Turn Yellow? Professional Anti-Yellowing Solutions for Printing & Coating Industries

Comprehensive Guide to UV Lamp Fusing and Bending Issues: Causes, Solutions & Prevention

Guangzhou Weitai Electromechanical Invites You to 2025 Shenzhen International Film & Tape Expo to Explore Innovative Water-Cooled UV/LED System

The core components and operation process of UV system (In offset printing press)

Showcasing at All Print Indonesia 2025: Water-Cooled UV Systems Empower Large-Scale Printing Equipment

You may also like

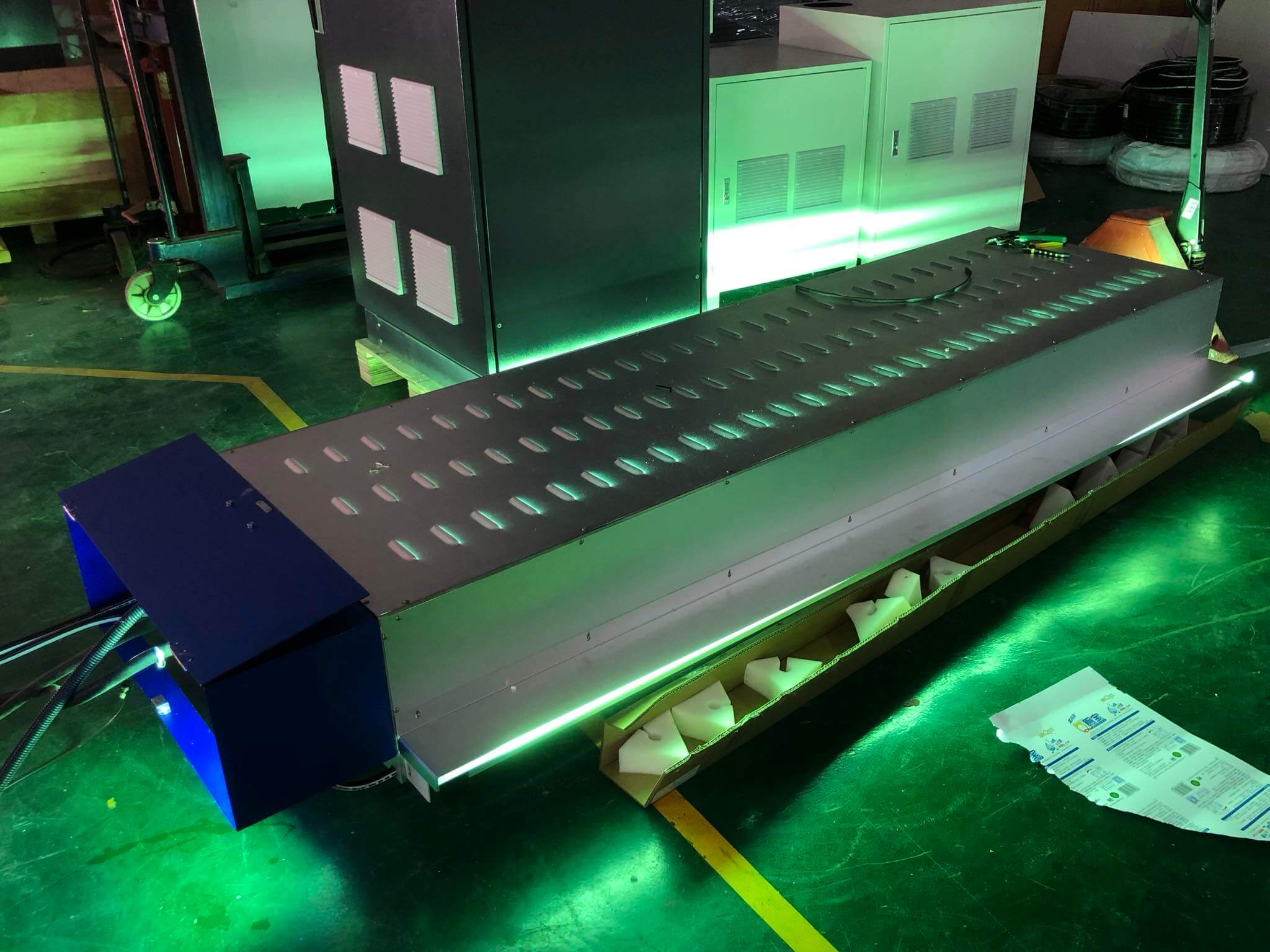

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Offset LED pre-press testing machine

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang