Professional-Grade UV Spot Curing System for Industrial, Medical, and Electronics Manufacturing

Introducing the UV Spot Curing System, the ultimate solution for precise and efficient curing of UV-curable adhesives, coatings, and inks. Our state-of-the-art system is designed to meet the needs of industrial, medical, and electronics manufacturing applications, providing reliable performance and peace of mind for our users.

With its advanced UV technology, our spot curing system delivers uniform and consistent curing results, ensuring high-quality bond strength and durability. The user-friendly interface and intuitive controls make it easy to operate, while the compact and durable design allows for seamless integration into any production environment. Whether you're working with small or large components, our UV spot curing system offers unmatched flexibility and precision, guaranteeing optimal results every time.

At our core, we are committed to delivering professional-grade products that our customers can trust. Our spot curing system is backed by years of expertise in product operations, ensuring reliability and consistent performance. From its high-quality components to its advanced features, our UV spot curing system is engineered to meet the highest standards of excellence, making it the perfect choice for manufacturers looking to elevate their production processes.

By choosing our UV spot curing system, you can be confident in its ability to enhance productivity, streamline workflows, and deliver exceptional results. Trust in our dedication to excellence and let our UV spot curing system take your manufacturing operations to the next level.

Detailed display

Advantages

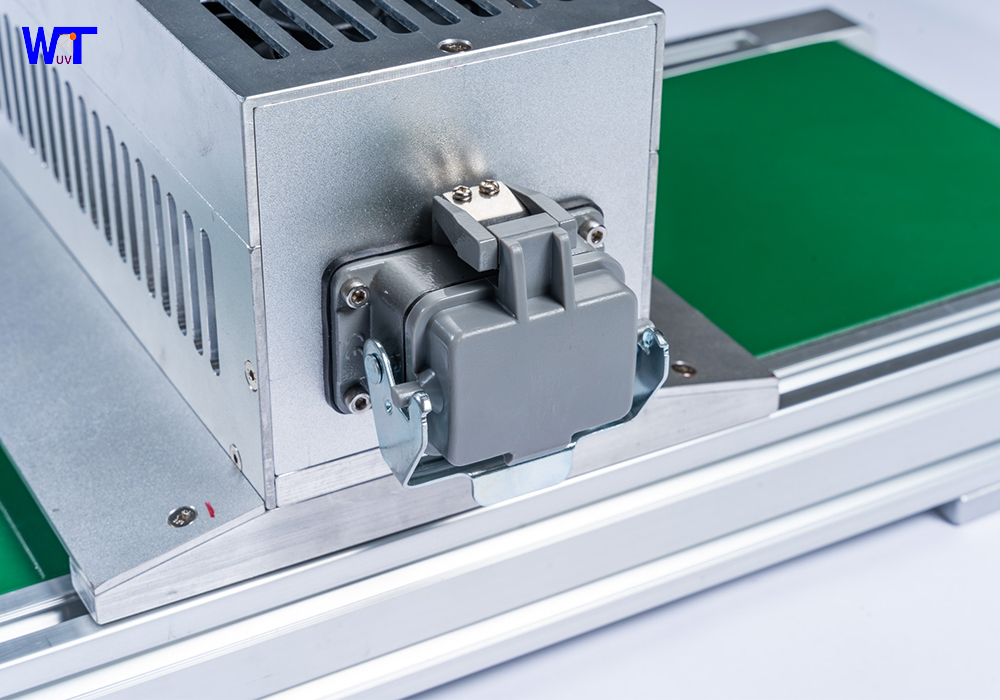

The light source head adopts a modular design.

Can be designed and customized development, a variety of optical wavelength optional.

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

It adopts special military-grade UVLED constant current power supply, which has intact short circuit protection, leakage protection, overcurrent and overvoltage protection, and undervoltage protection.

Frequently Asked Questions

What's the cooling way?

What is the major advantages of UV LED curing system’s than other UV curing system?

How does your factory do the quality control?

Are you a trader or manufacturer?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang