The Ultimate Guide to UV Curing Lights: How They Work and Why You Need Them

1. Introduction to UV Curing Lights

UV curing lights are an essential part of various industrial processes, including printing and coating applications. This section will provide an overview of how these lights work and their significance in the production process.

Sub1. What are UV Curing Lights?

UV curing lights, also known as ultraviolet curing lights, are specialized light sources that emit high-intensity ultraviolet radiation. This radiation is used to cure, or dry, inks, coatings, adhesives, and other materials during the production process.

Sub2. How Do UV Curing Lights Work?

UV curing lights work by triggering a chemical reaction in photo-reactive substances, such as inks and coatings, to harden and cure them. When exposed to UV light, these materials undergo a process known as photo-polymerization, which results in a durable, high-quality finish.

2. Benefits of UV Curing Lights

This section will delve into the various benefits of using UV curing lights in industrial applications, such as increased production efficiency, enhanced quality, and environmental sustainability.

Sub1. Increased Production Efficiency

UV curing lights offer rapid curing times, allowing for faster production speeds and reduced downtime. This results in higher productivity and cost savings for manufacturers.

Sub2. Enhanced Quality and Durability

UV curing lights facilitate the production of high-quality, durable finishes that are resistant to scratching, fading, and chemicals. This ensures that products maintain their integrity and appearance over time.

3. Applications of UV Curing Lights

UV curing lights find widespread use in a variety of industries, including printing, packaging, automotive, electronics, and healthcare. This section will explore the specific applications of UV curing lights and their role in each industry.

Sub1. Printing and Packaging

UV curing lights are essential for the rapid and efficient curing of inks and coatings in the printing and packaging industry. They enable high-speed production and the creation of vibrant, long-lasting printed materials.

Sub2. Electronics and Healthcare

In the electronics and healthcare industries, UV curing lights are used to bond and seal components, as well as to disinfect and sterilize medical equipment. Their precise curing capabilities make them indispensable for these applications.

4. Choosing the Right UV Curing System

Selecting the appropriate UV curing system is crucial to achieving optimal results in industrial processes. This section will provide guidance on choosing the right UV curing system for specific applications and production requirements.

Sub1. Factors to Consider

When selecting a UV curing system, factors such as the type of material to be cured, production speed, and curing space should be taken into account. Understanding these factors is essential for choosing a system that meets the specific needs of a production line.

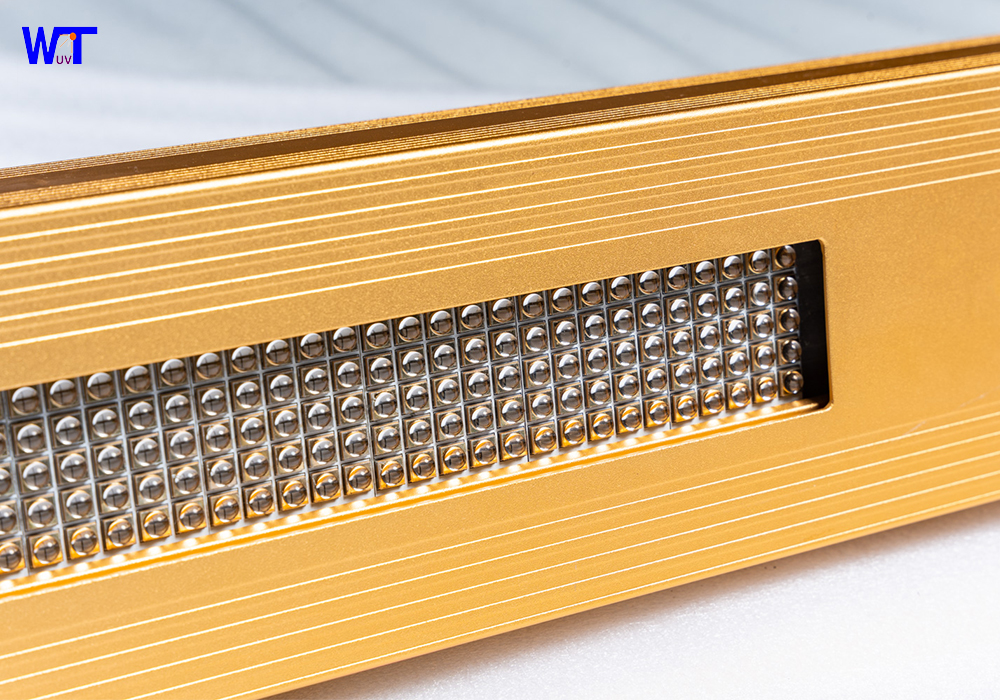

Sub2. Vtech Co., Ltd UV Curing Systems

Vtech Co., Ltd offers a wide range of water-cooled UV curing systems and LED UV curing systems tailored to various printing and coating applications. With their expertise and patented technology, Vtech Co., Ltd provides reliable and efficient UV curing solutions for diverse industrial requirements.

5. Maintenance and Care of UV Curing Lights

Proper maintenance and care are essential for ensuring the longevity and efficiency of UV curing lights. This section will provide tips for upkeep, including cleaning and servicing techniques to prolong the lifespan of these critical components.

Sub1. Cleaning and Inspection

Regular cleaning and inspection of UV curing light components, such as the lamp, reflector, and cooling system, are essential for preventing debris buildup and maintaining optimal performance.

Sub2. Servicing and Repairs

Scheduled servicing and timely repairs by qualified professionals are crucial for addressing wear and tear, as well as ensuring the consistent output and effectiveness of UV curing lights.

Conclusion

UV curing lights play a vital role in the production of high-quality, durable goods across various industries. Understanding the benefits, applications, and maintenance of these lights is essential for optimizing production processes and achieving superior results.

FAQs:

1. Are UV curing lights safe to use in industrial settings?

UV curing lights are safe for use in industrial settings when handled and maintained correctly. Proper safety precautions and protective measures should be followed to minimize exposure to UV radiation.

2. How long do UV curing lights last?

The lifespan of UV curing lights can vary depending on usage and maintenance. With regular cleaning and servicing, UV curing lights can often last several thousand hours before requiring replacement.

3. Can UV curing lights be used for food packaging applications?

UV curing lights can be used in food packaging applications, as they are capable of rapidly and efficiently curing inks and coatings without leaving harmful residues.

4. What are the environmental benefits of UV curing lights?

UV curing lights produce little to no volatile organic compounds (VOCs) and emit minimal heat, making them an environmentally friendly choice for industrial processes.

5. Are Vtech Co., Ltd UV curing systems customizable for specific production needs?

Yes, Vtech Co., Ltd offers customizable UV curing systems tailored to specific production requirements. Their expertise and patented technology enable them to provide reliable and efficient UV curing solutions for diverse industrial applications.

The Ultimate Guide to UV Curing Lights: How Vtech Co., Ltd Revolutionizes the Industry

The Ultimate Guide to UV Cure Light for Efficient Production

How WT's Automated UV Curing System Revolutionizes Manufacturing Processes

Understanding the Working Mechanism of UV Cure Adhesive

normal

Where is your factory located?

What's the whole UV LED curing system including?

Can I use my own PLC and Electric cabinet?

how can we guarantee quality?

How long will take for mass production?

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang