WT UV to LED Conversion System: Revolutionize Your Curing Process

In today's fast-paced industrial landscape, efficiency, sustainability, and quality are paramount. If you're using traditional UV curing systems, you might be facing rising energy costs, frequent bulb replacements, and operational limitations. It's time to evolve. WT by Vtech Co., Ltd offers a revolutionary solution: a seamless conversion of your existing UV light curing system to cutting-edge LED technology.

Transform Your Curing: The Power of WT LED Conversion

Stop wondering, can you turn a UV light curing system to LED? With WT, the answer is a resounding yes! Our expertise, honed since 2006, allows us to expertly transition your operations from conventional UV to superior LED curing. This isn't just an upgrade; it's a strategic move towards a more productive, cost-effective, and environmentally responsible future.

Unmatched Efficiency & Cost Savings

Traditional UV systems consume vast amounts of energy and require frequent, costly bulb changes. WT's LED conversion drastically cuts down your operational expenses. Enjoy:

- Up to 70% Energy Reduction: Significant savings on electricity bills.

- Extended Lifespan: LED lamps last tens of thousands of hours, minimizing maintenance and downtime.

- Instant On/Off: No warm-up or cool-down, saving time and energy.

Superior Performance & Quality

LED curing systems from WT deliver consistent, high-intensity output, ensuring perfect cures every time.

- Consistent Curing: Uniform light distribution for flawless results across various substrates.

- Reduced Heat Emission: Ideal for heat-sensitive materials, preventing warping or damage.

- Faster Production Speeds: Achieve quicker cure times, boosting your throughput and efficiency.

Eco-Friendly & Safer Operations

Embrace a greener footprint and a safer working environment.

- Mercury-Free: Eliminate hazardous mercury disposal associated with traditional UV lamps.

- Zero Ozone Emission: Improve air quality and worker safety by removing harmful ozone.

- Lower Carbon Footprint: Contribute to environmental sustainability with reduced energy consumption.

The WT Advantage: Your Partner in Curing Innovation

Vtech Co., Ltd, with its WT brand, is a recognized leader in curing technology. Our extensive experience and numerous patents in both water-cooled UV and LED UV systems mean you're partnering with true experts. We understand the unique demands of offset, gravure, flexo, coatings, and silk screen print applications.

Tailored for Your Application

We don't offer one-size-fits-all solutions. Our team works closely with you to design an LED conversion that perfectly integrates with your existing press or production line, ensuring optimal performance and minimal disruption.

Ready to unlock the full potential of your production? Upgrade your UV system to WT LED curing today and experience the difference in efficiency, quality, and sustainability. Contact us to learn how WT can revolutionize your curing process.

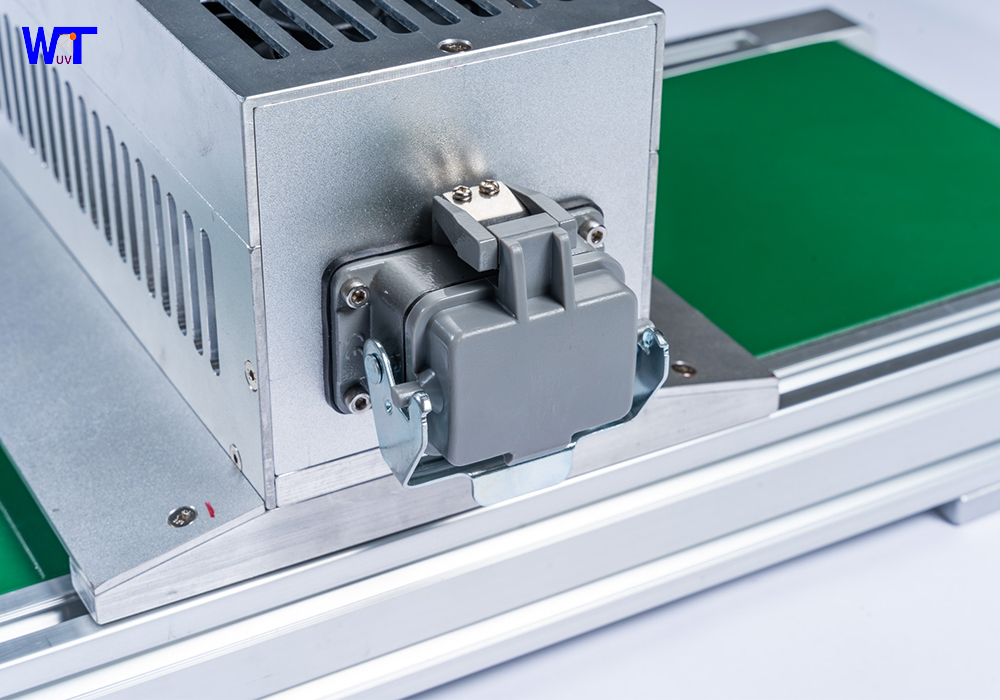

Product Images

Advantages

It adopts special military-grade UVLED constant current power supply, which has intact short circuit protection, leakage protection, overcurrent and overvoltage protection, and undervoltage protection.

The operation interface is simple, the sound and light alarm corresponds to the light source module, and the fault can be quickly determined.

We have over 17 years experience in UV curing industry.

With line disconnection alarm and LED dead point detection alarm function.

Question you may concern

Can you do a design for me or company?

How to cooperate with you and what is the cooperation process?

How to proceed an order for UV LED curing system?

What should I do when I don’t really know how to setting the printer parameters?

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang