WT UV Spot Curing System — Reliable, Fast Spot Curing

WT UV Spot Curing System — Fast, Reliable Spot Curing

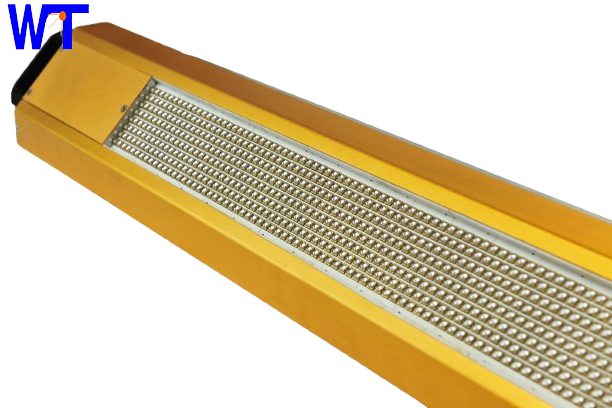

The WT UV Spot Curing System from Vtech Co., Ltd is designed to deliver precise, high-speed curing for spot applications in printing, coatings, and surface finishing. Built on decades of industry expertise and multiple patents, this compact unit ensures consistent results while improving production efficiency.

Key Benefits

- Fast curing for higher throughput and shorter cycle times.

- Accurate spot targeting reduces material waste and rework.

- Energy-efficient LED and water-cooled UV options to suit production needs.

- Compact design for easy installation on presses and inline systems.

Simple Integration and Use

WT units are easy to mount on offset, flexo, gravure, and screen-print presses or use as a standalone workstation. User-friendly controls let operators quickly set intensity and exposure time without needing deep technical knowledge.

Applications

Ideal for targeted curing in packaging, labels, varnishing, and spot coatings. Whether you need quick repairs, selective gloss, or local adhesion, the WT spot curing system delivers repeatable results across a variety of substrates.

Why Choose Vtech WT?

Established in 2006, Vtech Co., Ltd specializes in water-cooled and LED UV curing solutions and holds multiple industry patents. We combine practical design with proven technology to offer dependable products and responsive service—helping you reduce downtime and increase output.

Support and Service

We provide installation guidance, spare parts, and technical support to keep your system running smoothly. Our team has extensive experience across printing and coating industries to ensure reliable performance.

Contact us to discuss model options, power configurations, and integration support. Experience precise spot curing that saves time, materials, and cost with the WT UV Spot Curing System.

Picture Show

Advantages

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

Light source independent packaging(COB), long service life,energy saving, environ-ment friendly.

UV energy uniformity ≥ 98%.

24 Hours Service Hotline: All our team of service are fully conversant with our extensive range of products and can quickly and expertly talk you through any question you may ask. Vtech is committed to provide a 24 hours customer service/breakdown hotline in local office.

Question you may concern

How to cooperate with you and what is the cooperation process?

How long will take for mass production?

How does your factory do the quality control?

Can I use my own PLC and Electric cabinet?

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang