WT UV LED Curing System Dryer

Product Overview

The WT UV LED Curing System Dryer is a reliable, easy-to-use solution for fast UV curing in printing and coating applications. Developed by Vtech Co., Ltd — a specialist in water-cooled and LED UV curing systems since 2006 — this dryer combines stable performance, long LED life, and low operating temperatures to improve productivity and product quality.

Key Features

Performance & Efficiency

High-intensity LED modules cure inks and coatings quickly while consuming less power than traditional lamps. Low heat output protects substrates and reduces the need for cooling, helping maintain consistent speeds and reducing waste.

Design & Integration

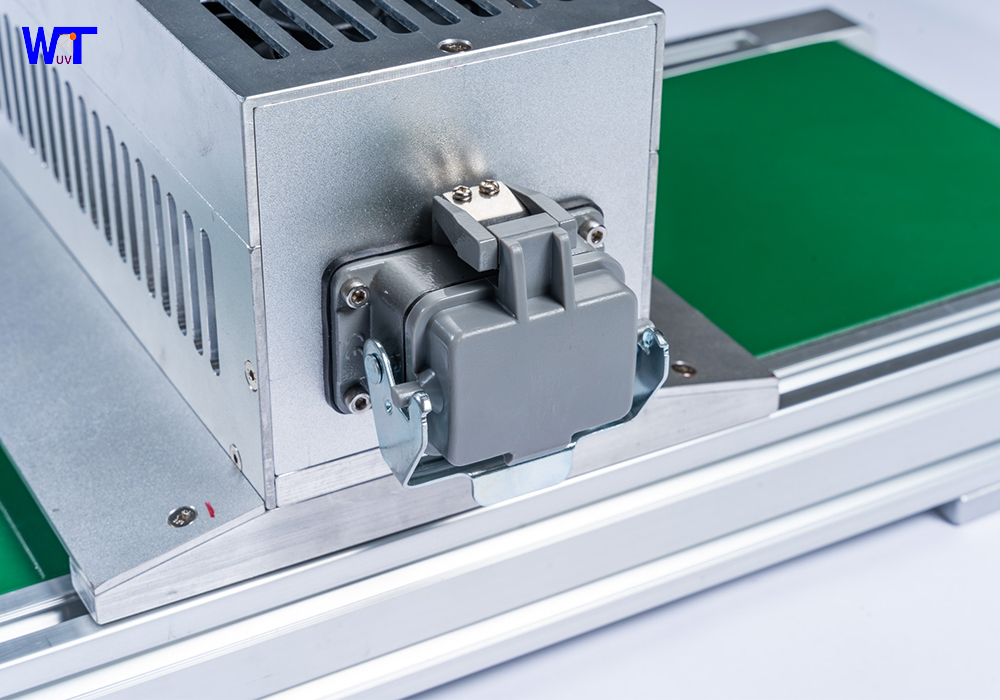

The compact, modular design allows easy integration into offset, gravure, flexo and screen printing lines. Adjustable intensity and simple controls let operators fine-tune curing without complex setup. Robust construction ensures long service life and low maintenance.

Benefits

- Faster production with immediate curing and reduced drying time.

- Lower energy costs and longer LED lifetime compared to traditional UV lamps.

- Minimal heat reduces substrate damage and improves print quality.

- Easy retrofitting to existing lines and straightforward operator controls.

- Reliable after-sales support from Vtech with industry patents and experience.

Applications

Ideal for a wide range of processes: offset press, flexo press, gravure press, coatings, and silk screen printing. Suitable for both new installations and upgrades where better efficiency and quality are required.

Why Choose WT & Vtech

Vtech has specialized in UV and LED curing systems since 2006, holding multiple industry patents and offering experienced technical support. Choosing the WT UV LED Curing System Dryer means investing in proven technology that boosts throughput, reduces costs, and delivers consistent, high-quality results.

Contact us to discuss how the WT system can fit your production line and improve your curing process.

Product Images

Advantages

With line disconnection alarm and LED dead point detection alarm function.

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

We have over 17 years experience in UV curing industry.

Question you may concern

Which wavelength do I need?

Where is your factory located?

Why choose Vtech's UV LED curing machine?

When can I get the quotations?

If you have any questions or concern, please contact us.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang