WT UV Lamp Curing Systems: Efficiency & Eco-Friendly Innovation

Introducing the WT UV Lamp Curing Systems – the pinnacle of innovation in curing technology. Our state-of-the-art systems are designed to meet the evolving needs of industries that prioritize efficiency, precision, and sustainability.

What sets WT UV Lamp Curing Systems apart is our commitment to delivering unparalleled performance and reliability. Our systems leverage advanced UV technology to provide fast and efficient curing of coatings, adhesives, and inks, ensuring perfect results every time. This innovation not only saves time but also vastly improves productivity, making it an essential tool for high-demand industrial settings.

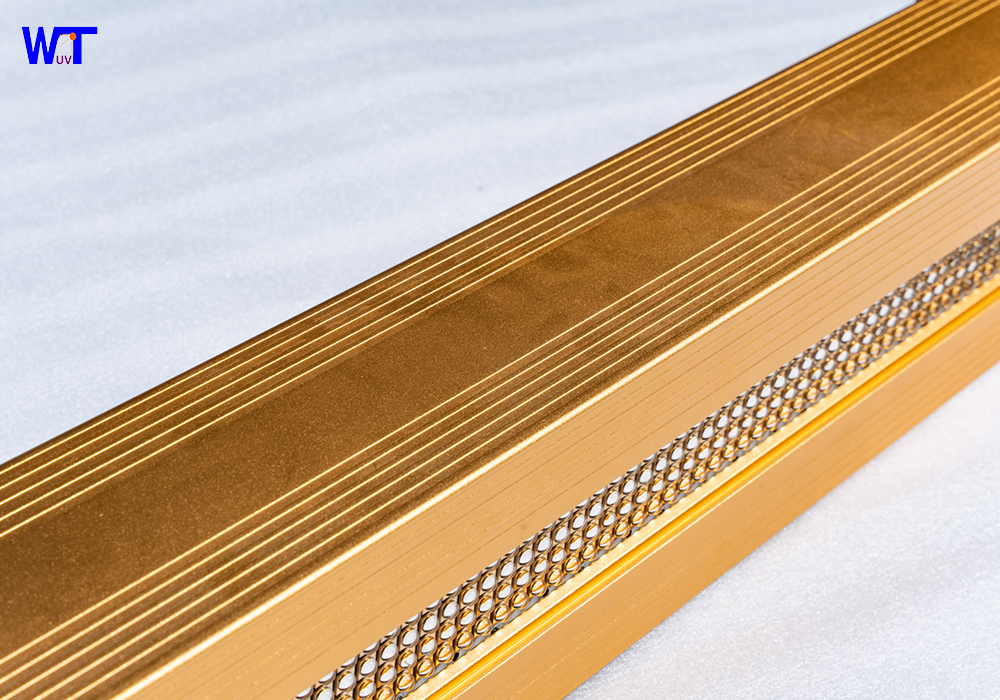

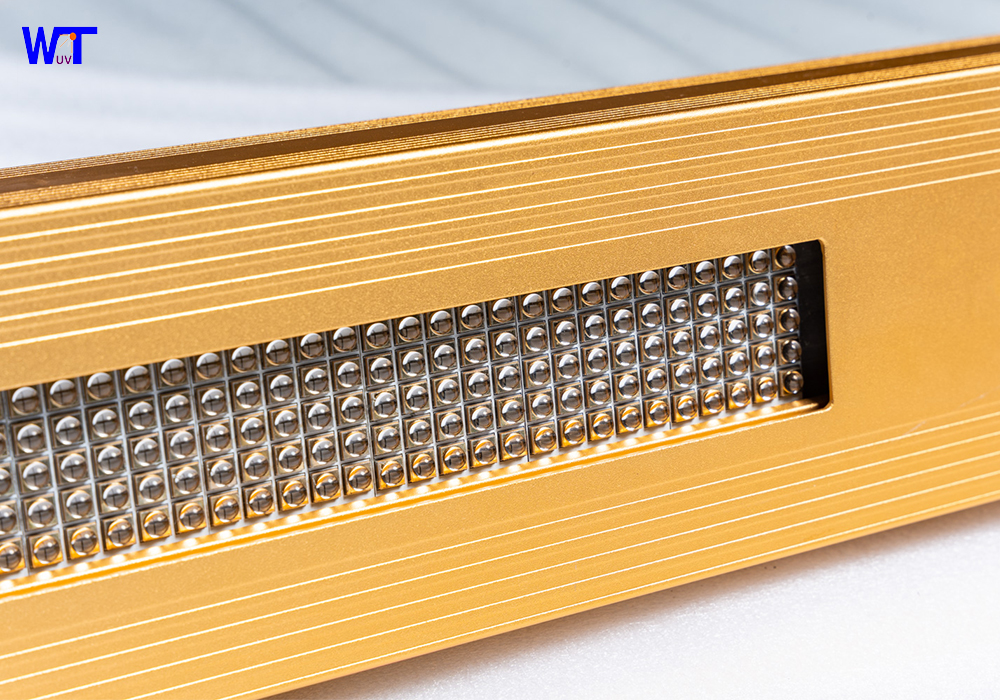

The unique design of our UV lamps maximizes energy efficiency and longevity, substantially reducing operational costs while maintaining superior curing quality. The user-friendly interface and customizable settings allow for seamless integration into any production line, offering a streamlined experience that doesn't compromise on quality or performance.

Moreover, our systems are eco-friendly, reducing the carbon footprint by minimizing energy consumption and eliminating the need for harmful chemicals. This makes WT UV Lamp Curing Systems the ideal choice for businesses looking to operate sustainably while maintaining high operational standards.

Choosing WT means choosing a partner that understands your industry-specific needs and offers solutions that contribute to your growth, performance, and success. Elevate your production capabilities with WT UV Lamp Curing Systems and experience the future of curing technology today.

Picture Show

Advantages

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

Can be designed and customized development, a variety of optical wavelength optional.

With stepless dimming function;

Q&A

When can I get the quotations?

What materials can UV printers print?

lf the light intensity is adjustable?

Why and how do I replace a UV led?

If you have any other questions, please write email to us or call us , we will reply you ASAP.

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang