WT UV Curing System for Offset Printing

Overview

WT UV curing systems from Vtech Co., Ltd are designed for offset printing applications that demand fast, consistent, and reliable curing. Built with years of industry experience and many patents, our water-cooled UV and LED UV solutions offer stable performance for a wide range of offset presses and print environments.

Why Choose WT for Offset Printing?

WT systems focus on three core needs of print shops: speed, consistency, and uptime. Our units cure inks and coatings quickly to allow immediate finishing and inline processing. The water-cooled design keeps temperature stable for consistent results, while LED options provide energy-efficient, low-heat curing for sensitive substrates.

Key Benefits

- Fast and uniform curing to increase throughput

- Stable temperature control with water-cooled models

- Energy-saving LED choices for lower operating cost

- Durable components and patented designs for long life

- Easy integration with many offset press brands

Reliable and Easy to Use

WT systems are built for real-world production. Controls are straightforward and maintenance is simple, so operators can focus on print quality rather than equipment headaches. Vtech's technical support and experienced service team ensure smooth installation and fast responses when needed.

Applications and Compatibility

Our UV and LED curing systems suit a variety of offset press configurations, including sheetfed and web offset. They're also compatible with other printing and coating processes, making them a flexible choice for mixed production lines.

Trust and Support

Founded in 2006, Vtech Co., Ltd combines deep product knowledge with patented innovations. WT UV curing systems come with strong after-sales support and quality assurance, giving you confidence in performance and reliability.

Contact us to learn how WT UV curing systems can improve curing speed, reduce downtime, and deliver consistent print quality for your offset press operations.

Product Images

Advantages

Light source independent packaging(COB), long service life,energy saving, environ-ment friendly.

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

Compact size, making it easy to integrate into fully automated production lines and equipment.

LEDs do not produce ozone gas.

Q&A

lf the light intensity is adjustable?

Why and how do I replace a UV led?

how can we guarantee quality?

What is the major advantages of UV LED curing system’s than other UV curing system?

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

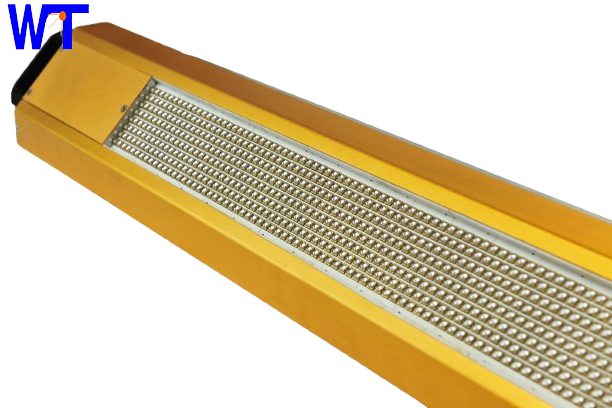

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang