WT UV Curing Inks: Superior Printing

WT UV Curing Inks: Superior Quality for Unmatched Performance

At WT, a trusted name in UV curing technology since 2006, we understand the importance of high-quality inks. That’s why we offer a range of superior UV curing inks designed to deliver exceptional results across various printing applications. Our inks are meticulously formulated to provide vibrant colors, sharp details, and outstanding durability. Whether you’re working with offset, gravure, flexo, screen printing, or coatings, our inks are engineered to seamlessly integrate with your existing Vtech UV curing system (or any compatible system).

We're committed to providing you with reliable, high-performing inks that enhance your productivity and meet the highest industry standards. Our experienced team provides expert support throughout the process, ensuring your success. Choose WT UV curing inks for vibrant prints, lasting quality, and peace of mind. Contact us today to learn more about our comprehensive range and find the perfect ink solution for your needs.

Product Image

Advantages

We are the source factory with professional R&D team and skilled workers.

Can be designed and customized development, a variety of optical wavelength optional.

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

With stepless dimming function;

Question you may concern

How long will take for mass production?

What is the major advantages of UV LED curing system’s than other UV curing system?

What should I do when I don’t really know how to setting the printer parameters?

Why choose Vtech's UV LED curing machine?

About other questions pls contact me directily.

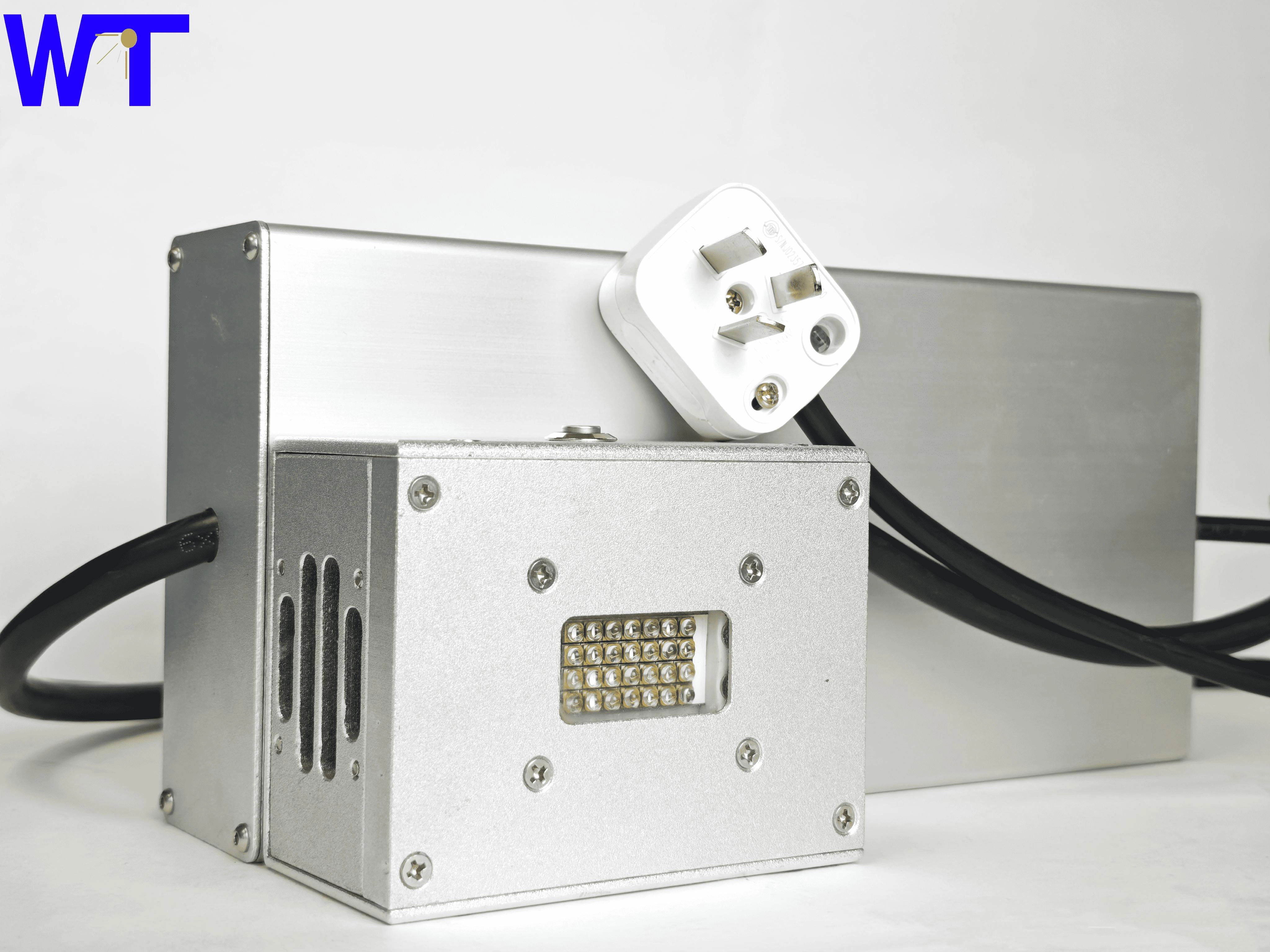

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

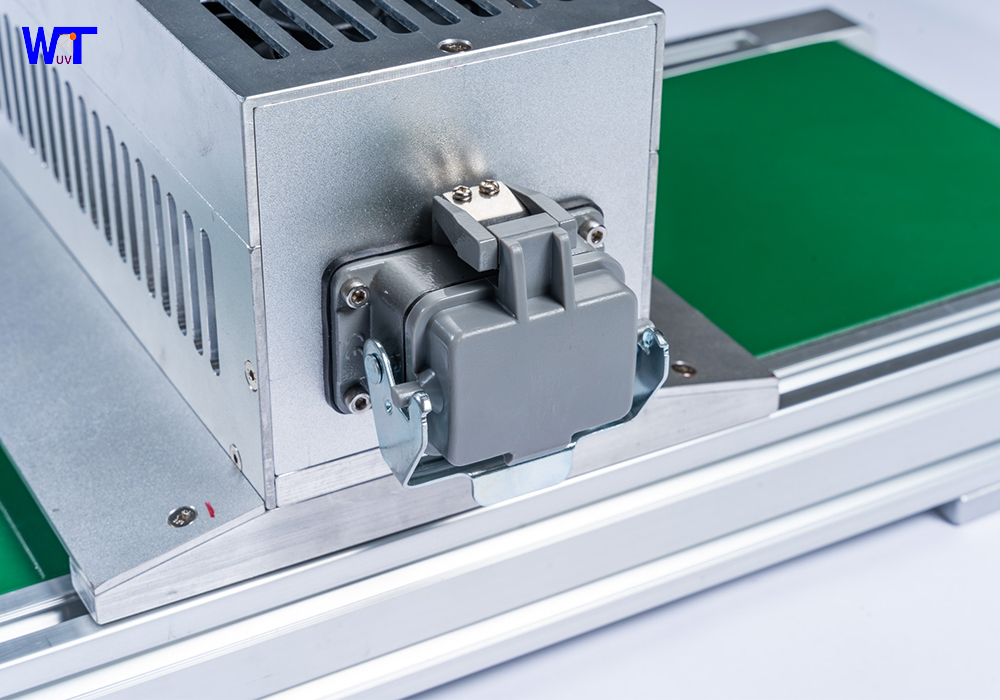

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang