WT UV Curing for Flexographic Printing

The Water-Cooled UV Shutter Housing is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

WT UV Curing for Flexographic Printing

Experience superior print performance with WT UV Curing for Flexographic Printing from Vtech Co., Ltd, a leading innovator in UV curing technology since 2006. Specializing in water-cooled UV curing systems and advanced LED UV curing systems, WT brings groundbreaking solutions designed for the dynamic flexographic printing industry.

Our UV curing systems optimize ink drying processes, ensuring vibrant, sharp prints with outstanding durability and adhesion—perfect for fast-paced flexographic production lines. The precision-controlled UV output accelerates curing times, increases throughput, and reduces energy consumption, making your operations both efficient and eco-friendly.

Backed by numerous industry patents, WT’s UV curing technology stands out with its unique water-cooled design, providing stable, long-lasting performance and reliable cooling, even under extreme workloads. We tailor each system to the specific needs of your press—be it offset, gravure, flexo, or screen printing—guaranteeing seamless integration and effortless operation.

With nearly two decades of expertise, Vtech’s dedicated R&D team is committed to delivering cutting-edge, customizable UV curing solutions that give you a decisive production advantage. Trust WT for responsive support, rapid installation, and robust after-sales service—empowering your flexographic printing operations to deliver High Quality quality at high speed, every time.

Elevate your print results, maximize energy savings, and streamline production with WT UV Curing for Flexographic Printing—where innovation meets reliability.

Picture Show

Our Advantages

24 Hours Service Hotline: All our team of service are fully conversant with our extensive range of products and can quickly and expertly talk you through any question you may ask. Vtech is committed to provide a 24 hours customer service/breakdown hotline in local office.

It adopts special military-grade UVLED constant current power supply, which has intact short circuit protection, leakage protection, overcurrent and overvoltage protection, and undervoltage protection.

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

Limmediately on and off without preheating. The irradiation intensity can reach 500mw/cm2-- 12000mw/cm2 or higher.

Q&A

Why and how do I replace a UV led?

Are you a trader or manufacturer?

how can we guarantee quality?

What materials can UV printers print?

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

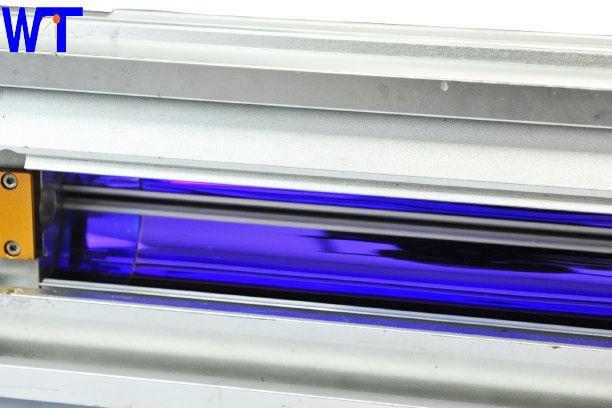

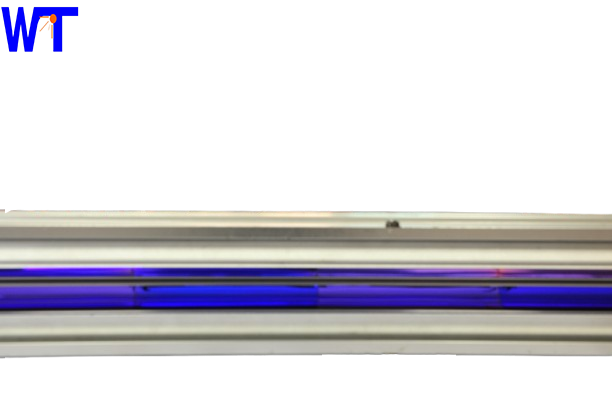

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Offset LED pre-press testing machine

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang