WT Printing UV Curing Systems

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

WT Printing Solutions: Advanced UV Curing Systems for Superior Printing Results

WT, a leading brand under Vtech Co., Ltd, stands at the forefront of the printing industry, delivering exceptional water-cooled UV curing systems and LED UV curing systems since 2006. Specializing in the research, development, and production of cutting-edge UV and LED curing technology, WT has earned numerous patents and a trusted reputation for innovation and reliability.

Designed for offset press, gravure press, flexo press, coatings, and silk screen print applications, WT’s systems ensure precise, consistent, and high-speed curing across a wide range of printing processes. Our engineering expertise ensures that every product delivers outstanding performance, energy efficiency, and durability, catering to the evolving needs of modern printing businesses.

With nearly two decades of experience, WT is committed to providing tailored solutions and comprehensive support for every customer. Whether you require industry-leading reliability for demanding production lines or versatile curing for specialty printing, our team is ready to assist you at every step. Our global customer base trusts WT for efficient production, prompt service, and peace of mind for mission-critical operations.

Choose WT and experience the confidence of partnering with a pioneer in advanced printing technology. Discover why professionals worldwide rely on WT UV curing systems to enhance their printing results and drive business growth.

Product Images

Advantages

Light source independent packaging(COB), long service life,energy saving, environ-ment friendly.

LEDs do not produce ozone gas.

With line disconnection alarm and LED dead point detection alarm function.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

Question you may concern

What materials can UV printers print?

What's the whole UV LED curing system including?

When can I get the quotations?

What should I do when I don’t really know how to setting the printer parameters?

If you have any questions or concern, please contact us.

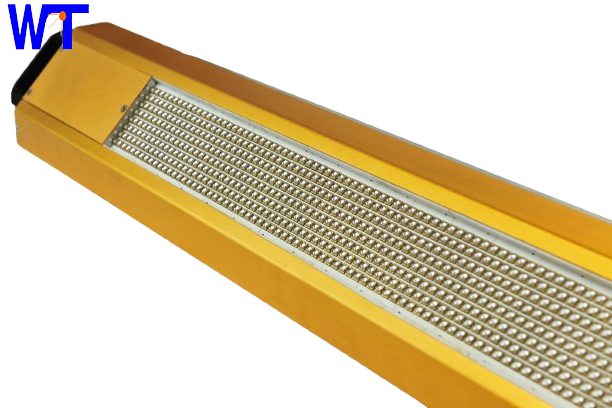

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Small UV drying machine

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Customized conveyor belt type UV LED curing equipment

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang