WT Mercury UV Curing System for Bobst Flexo Presses: Precision & Performance

Unlock the full potential of your Bobst Flexo Printing Press with the WT Mercury UV Curing System, brought to you by Vtech Co., Ltd. Established in 2006, Vtech has been at the forefront of UV curing technology, specializing in innovative water-cooled and LED UV solutions. With numerous industry patents and a deep commitment to research and development, our WT brand systems are engineered to deliver unparalleled performance and reliability for diverse printing applications.

Elevate Your Bobst Flexo Printing with WT Mercury UV Curing

Designed specifically to complement the demanding requirements of Bobst Flexo presses, the WT Mercury UV Curing System is a testament to Vtech's engineering excellence. It’s more than just a curing system; it’s a commitment to superior print quality and operational efficiency.

Engineered for Precision and Speed

Experience fast, uniform, and complete curing that significantly boosts your production throughput. Our advanced water-cooled mercury UV lamps ensure rapid ink drying, delivering vibrant colors, sharp details, and durable, scratch-resistant finishes. This system keeps pace with high-speed flexo operations, minimizing bottlenecks and maximizing output without compromising quality.

Unmatched Reliability and Performance

At Vtech Co., Ltd, reliability is built into every WT system. Leveraging our extensive expertise and patented technologies, this Mercury UV Curing System offers consistent, stable performance even under continuous, heavy-duty use. Printers can count on reduced downtime, fewer reprints, and a longer lifespan for their equipment, translating into significant cost savings and peace of mind. Our rigorous quality control ensures every unit meets the highest industrial standards.

Seamless Integration and Expert Support

The WT Mercury UV Curing System is designed for straightforward integration into your existing Bobst Flexo Printing Press setup. Vtech's professional team provides comprehensive support, from installation guidance to ongoing maintenance advice, ensuring a smooth transition and optimal operation. Trust in a partner with proven experience in diverse printing sectors, dedicated to your success. Choose WT for a reliable, high-performance UV curing solution that enhances your Bobst Flexo printing capabilities. Experience the difference that professional engineering, advanced technology, and dedicated support from Vtech Co., Ltd can make.

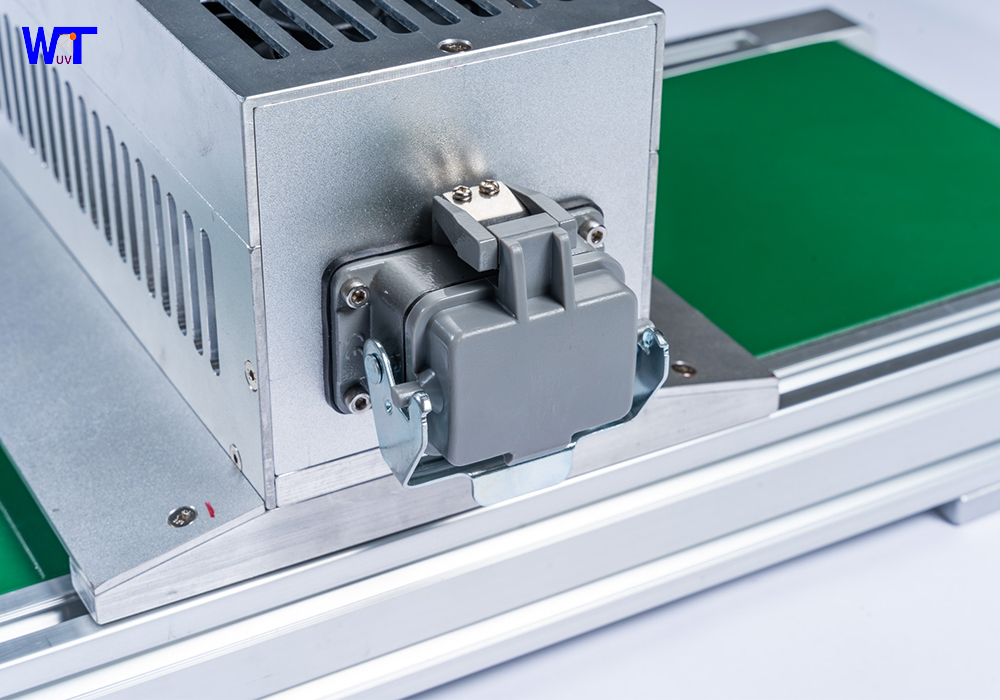

Product Image

Our Advantages

LEDs do not produce ozone gas.

With line disconnection alarm and LED dead point detection alarm function.

It adopts special military-grade UVLED constant current power supply, which has intact short circuit protection, leakage protection, overcurrent and overvoltage protection, and undervoltage protection.

Can be designed and customized development, a variety of optical wavelength optional.

FAQ

how can we guarantee quality?

Why and how do I replace a UV led?

What is the major advantages of UV LED curing system’s than other UV curing system?

How to proceed an order for UV LED curing system?

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang