WT LED UV Curing System - Fast, Efficient Industrial Curing

WT LED UV Curing System — Reliable Curing for Industrial Production

WT LED UV curing systems from Vtech Co., Ltd are designed to bring fast, consistent and energy-efficient curing to your production line. Built on years of experience and multiple industry patents, our systems serve offset, gravure, flexo presses, coatings and silk screen printing with dependable performance and minimal downtime.

Practical Benefits

- Fast curing speeds that increase throughput and reduce bottlenecks.

- Energy-efficient LED sources lower power costs compared to traditional lamps.

- Low heat output protects substrates and reduces waste from overheating.

- Long lamp lifetime and stable output cut maintenance and replacement costs.

- Compact, easy-to-install units minimize line modification and setup time.

Applications

WT systems are versatile and suitable for a wide range of applications: offset printing, gravure, flexo, coatings, and silk screen printing. Whether you need high-speed curing for labels or precise coating cures for industrial parts, WT provides tailored solutions.

Why Choose WT and Vtech?

Vtech Co., Ltd, established in 2006, specializes in water-cooled and LED UV curing systems. With extensive R&D, multiple patents, and practical production experience, we deliver reliable equipment and strong after-sales support. Our team helps you choose the right model, integrates the system with your line, and offers responsive service to keep production running smoothly.

Customer Value

We focus on real-world benefits: improved efficiency, lower operating costs, and reduced waste. Our clear documentation and hands-on support make installation and operation straightforward. Choosing WT means investing in a proven system that values your uptime and output quality.

If you want a compact, energy-saving, and durable LED UV curing solution for industrial printing or coatings, WT LED UV curing systems offer measurable improvements in speed, cost, and reliability.

Product Image

Our Advantages

LEDs do not produce ozone gas.

With stepless dimming function;

Compact size, making it easy to integrate into fully automated production lines and equipment.

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

Q&A

What is the major advantages of UV LED curing system’s than other UV curing system?

What's the cooling way?

What materials can UV printers print?

Why choose Vtech's UV LED curing machine?

Customized conveyor belt type UV LED curing equipment

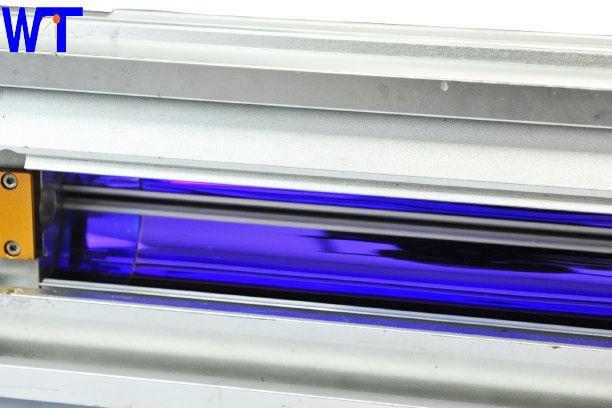

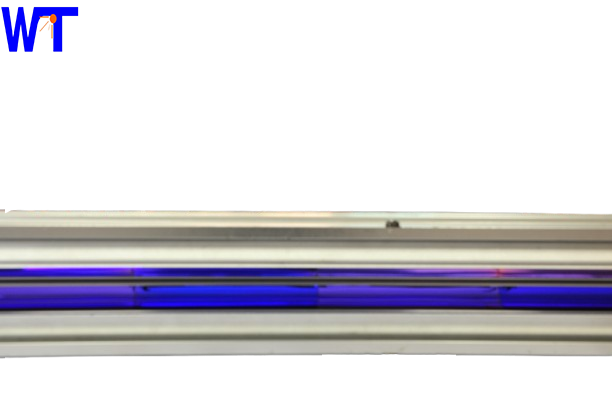

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang