WT Green Spot UV Curing System

Elevate Your Production with WT Green Spot UV Curing System

The WT Green Spot UV Curing System by Vtech Co., Ltd represents a leap forward in targeted curing technology. Designed for precision and efficiency, this innovative system provides instant, powerful UV curing exactly where you need it, minimizing energy consumption and maximizing product quality. It’s an ideal solution for businesses aiming to achieve superior finishes while embracing sustainable practices.

Why Choose WT Green Spot UV?

When precision and performance matter, the WT Green Spot UV System delivers unmatched value. Leveraging Vtech's extensive experience and patented technologies since 2006, this system is engineered to meet the demanding needs of modern printing and coating applications.

Precision Perfected for Spot Applications

Unlike full-area curing, our Green Spot UV system focuses its powerful UV energy on specific, pre-defined areas. This not only ensures a flawless, high-gloss finish or critical curing on intricate designs but also significantly reduces wasted energy. Achieve sharp, durable results on labels, packaging, selective coatings, and more, with unparalleled accuracy.

Embrace Eco-Friendly Green Technology

The Green in our system signifies its commitment to environmental responsibility. Utilizing advanced, energy-efficient components, the WT Green Spot UV dramatically lowers power consumption compared to traditional methods. Its instant on/off capabilities eliminate warm-up times and standby power drain, reducing your carbon footprint and operational costs.

Enhanced Durability and Flawless Finishes

Rapid and complete curing ensures superior adhesion and an exceptionally durable finish. Products processed with the WT Green Spot UV System exhibit enhanced scratch resistance, chemical resistance, and a vibrant, long-lasting appearance. Impress your clients with consistent, high-quality output that stands the test of time.

Key Features & high quality Benefits

The WT Green Spot UV Curing System is packed with features designed for operational excellence:

- Optimized Energy Efficiency: Significant power savings due to targeted curing and instant operation.

- Pinpoint Precision Curing: Ideal for intricate designs, selective gloss, or specific coating applications.

- Instant On/Off: No warm-up delays, boosting productivity and further saving energy.

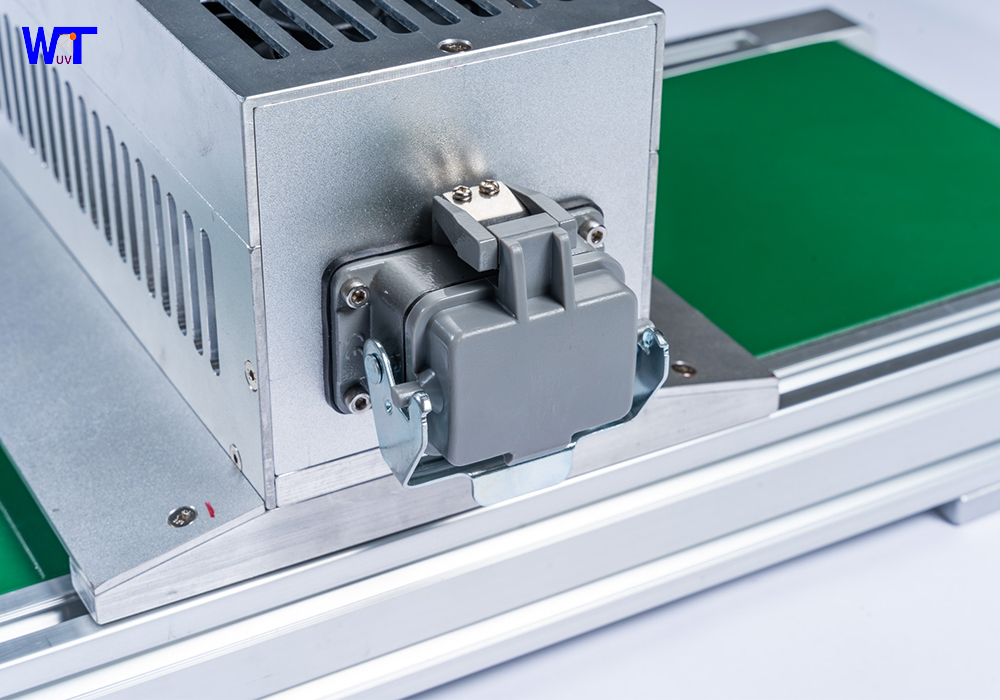

- Compact & Adaptable Design: Easily integrates into existing offset, gravure, flexo presses, and other coating lines.

- Long-Lasting Performance: Built with robust components for reliability and minimal maintenance.

About Vtech Co., Ltd – Your Trusted Partner

As Vtech Co., Ltd, established in 2006, we pride ourselves on being leaders in UV and LED curing solutions. With numerous patents and a rich history of serving diverse industries from offset to silk screen print, our expertise ensures you receive a product that is not just advanced, but also exceptionally reliable.

Unlock Superior Curing Performance Today

Invest in the WT Green Spot UV Curing System and transform your production. Experience the perfect blend of precision, efficiency, and environmental responsibility. Contact Vtech Co., Ltd today to discover how our WT Green Spot UV system can elevate your product quality and streamline your operations.

Detailed display

Advantages

The light source head adopts a modular design.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

With line disconnection alarm and LED dead point detection alarm function.

Q&A

Can I use my own PLC and Electric cabinet?

How to proceed an order for UV LED curing system?

lf the light intensity is adjustable?

How does your factory do the quality control?

About other questions pls contact me directily.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang