WT edale fl13 UV Curing System: Elevate Your Printing & Coating Performance

WT edale fl13 UV Curing System: Elevate Your Printing & Coating Performance

In today's fast-paced production environment, efficiency, quality, and reliability are paramount. Vtech Co., Ltd, a leader in UV curing technology since 2006, proudly presents the WT edale fl13 UV Curing System – a testament to our commitment to innovation and excellence. As specialists in water-cooled and LED UV curing systems, our patented solutions empower businesses across offset, gravure, flexo, silk screen printing, and various coating applications to achieve superior results.

Your Competitive Edge with the WT edale fl13

The WT edale fl13 UV Curing System is meticulously engineered to meet the demanding requirements of modern industrial processes. Designed for seamless integration and optimal performance, it offers a transformative upgrade for your production line.

Unmatched Performance & Speed

Experience a significant boost in your operational efficiency. The edale fl13 system delivers rapid and complete UV curing, drastically reducing drying times and allowing for immediate post-processing. This acceleration translates directly into higher throughput, lower energy consumption, and a streamlined workflow that keeps your production moving at an optimal pace.

Superior Quality & Durability

Elevate the quality of your printed products and coated surfaces. Our advanced UV curing technology ensures vibrant, sharp, and consistent results, enhancing visual appeal. Beyond aesthetics, the cured materials exhibit exceptional durability, scratch resistance, and chemical resistance, extending the lifespan and performance of your products.

Versatility for Diverse Applications

The WT edale fl13 is a versatile solution crafted to support a wide array of industrial applications. Whether you're running a flexo press, an offset machine, a gravure line, a silk screen operation, or applying industrial coatings, this system provides consistent, high-quality curing. Its adaptability makes it an invaluable asset for businesses looking to enhance multiple facets of their production.

Engineered for Reliability by Vtech

Choosing the WT edale fl13 means investing in a system backed by Vtech Co., Ltd's nearly two decades of expertise. Our extensive experience, numerous industry patents, and dedication to research and development ensure that you receive a robust, dependable, and long-lasting UV curing solution. We understand the critical nature of your production, and our systems are built for unwavering performance and minimal downtime.

Why Partner with Vtech for Your UV Curing Needs?

At Vtech, we don't just sell equipment; we provide solutions that drive success. Our rich experience and deep understanding of UV and LED curing systems enable us to offer reliable service and efficient production support. With the WT edale fl13 UV Curing System, you gain more than just a piece of machinery – you gain a strategic partner committed to enhancing your productivity, product quality, and overall operational excellence. Join the multitude of businesses that trust Vtech for their advanced curing needs.

Detailed display

Our Advantages

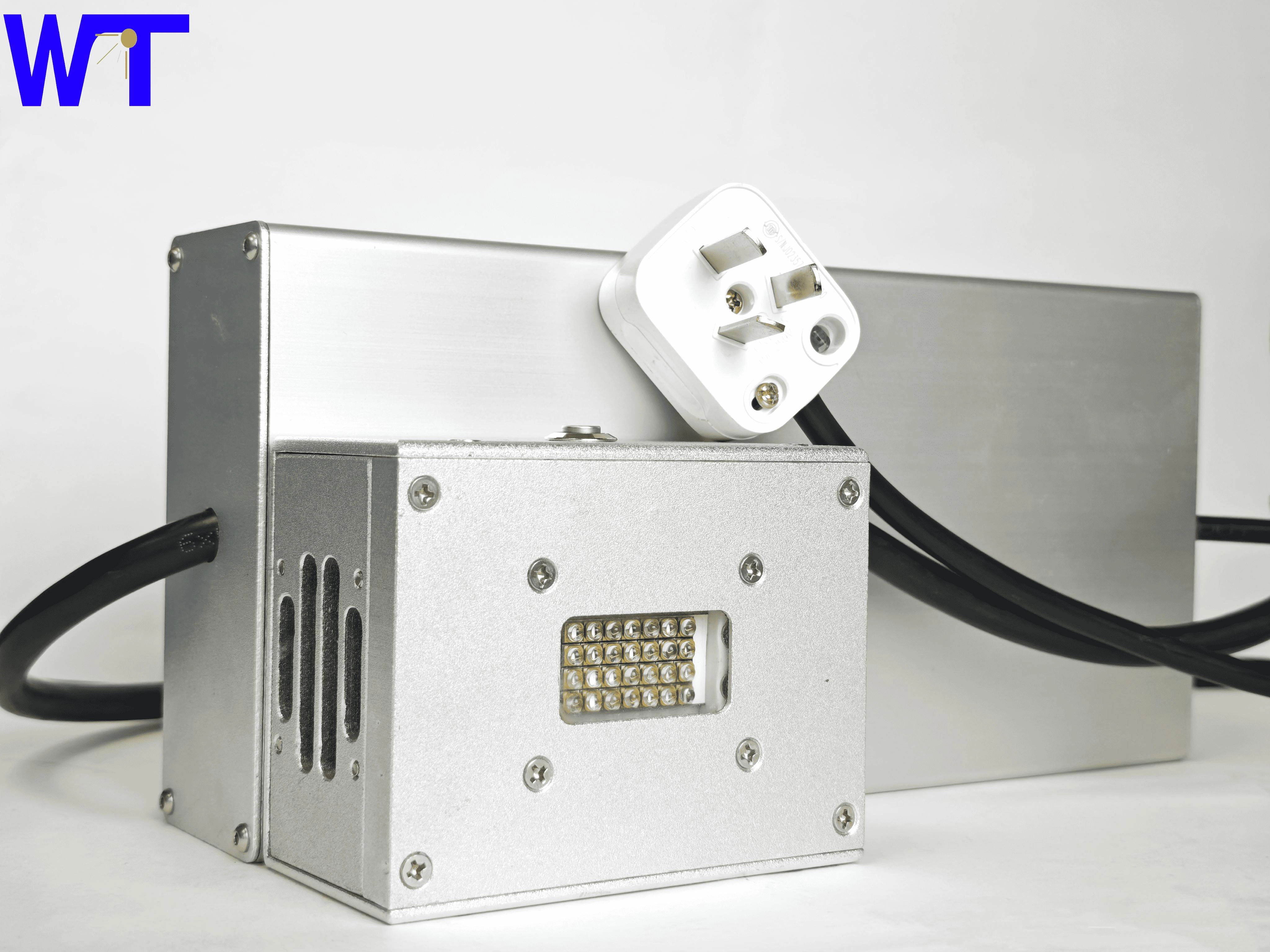

The light source head adopts a modular design.

Light source independent packaging(COB), long service life,energy saving, environ-ment friendly.

It applies to the gold and silver cardboard, metal, glass, plastic and other substrates printed wrinkles, scrub, refraction, light crystal stones, colorful powder, convex oil, snow and other special effects, and offset print UV offset ink light cured.

Low energy consumption, about 55%-80% of the traditional type. It can reduce the cost.

Q&A

What's the cooling way?

What's the Peak Irradiance do I need?

How to cooperate with you and what is the cooperation process?

Why choose Vtech's UV LED curing machine?

If you have any other questions, please write email to us or call us , we will reply you ASAP.

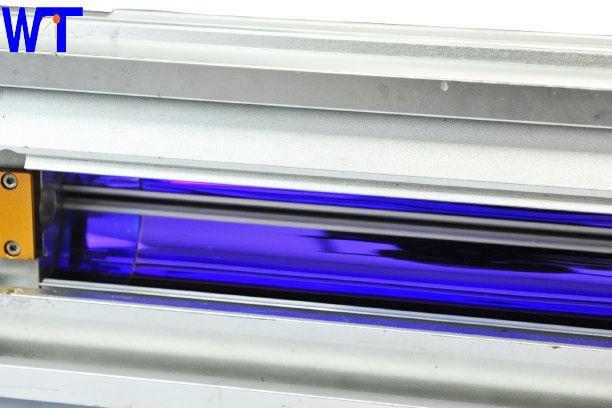

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

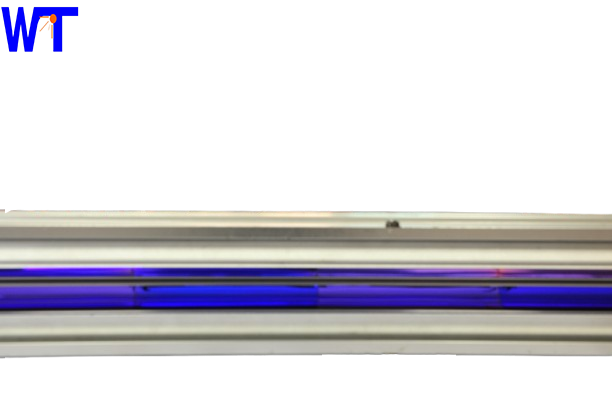

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Traditional UV Curing System for Screen / Offset Ink with 3UV Modularized Cassettes

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang