WT CuringInk UV Curing Systems — Reliable UV & LED Solutions

About WT CuringInk

WT CuringInk by Vtech Co., Ltd is a line of UV and LED curing systems designed for consistent, high-quality ink and coating curing. Since 2006, Vtech has specialized in water-cooled and LED UV curing technology, holding multiple industry patents. Our systems serve offset, gravure, flexo presses, coatings, and screen printing with proven reliability and simple integration.

Key Benefits

Reliable Performance

WT CuringInk units deliver stable, repeatable curing power, ensuring consistent print quality and fewer production interruptions. Built with durable components and intelligent controls, they reduce downtime and maintenance needs.

Energy Efficiency & Safety

Our LED UV models save energy and reduce heat, while water-cooled systems maintain optimal lamp temperature for long life. Safety features include protective housings, easy-access service panels, and monitoring systems that help protect operators and equipment.

Easy Integration

WT CuringInk is designed to fit existing press lines and coating setups. Compact footprints, flexible mounting options, and straightforward controls make installation fast and commissioning simple. Clear documentation and responsive support help you start production quickly.

Applications

WT CuringInk works across a wide range of industries: commercial offset, flexible packaging, gravure printing, label and tag production, textile printing, and industrial coatings. Whether you need rapid surface cure or deep crosslinking for coatings, our product line offers tailored solutions.

Why Choose WT and Vtech

Vtech brings decades of hands-on experience and patented innovations to every WT CuringInk product. Our customers trust us for consistent output, robust design, and dependable after-sales service. We focus on real-world performance—less jargon, more uptime.

Specifications & Support

WT CuringInk systems are available in multiple power ranges and configurations, including water-cooled mercury arc and modern LED UV options. Each unit comes with installation guidance, routine maintenance tips, and access to Vtech technical support. For custom needs, our engineers can recommend the best model and setup.

Choose WT CuringInk for a dependable, efficient, and easy-to-use curing solution that helps you meet production goals with confidence. Contact our team to learn which model fits your process.

Picture Show

Advantages

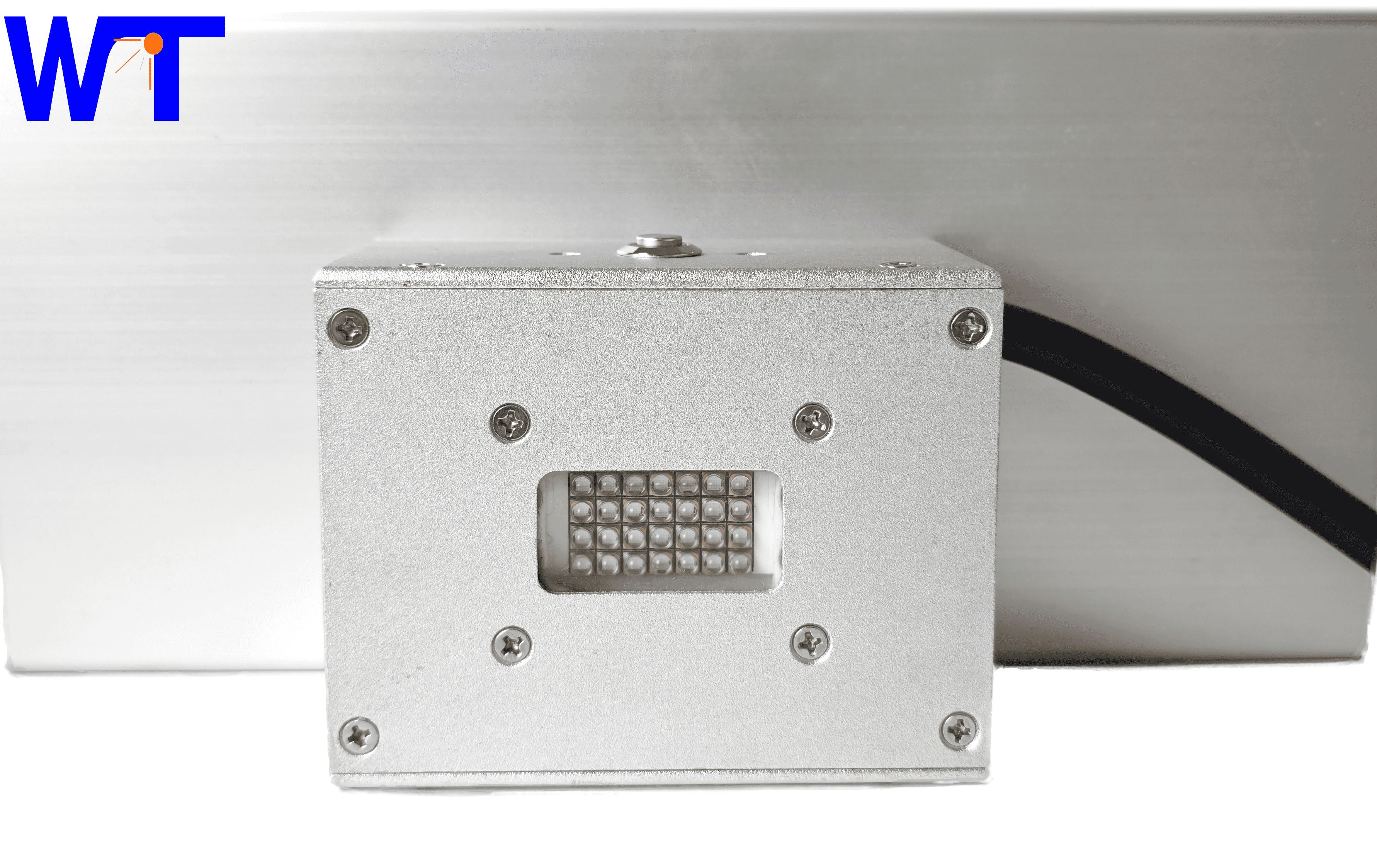

Compact size, making it easy to integrate into fully automated production lines and equipment.

With stepless dimming function;

We are the source factory with professional R&D team and skilled workers.

24 Hours Service Hotline: All our team of service are fully conversant with our extensive range of products and can quickly and expertly talk you through any question you may ask. Vtech is committed to provide a 24 hours customer service/breakdown hotline in local office.

Frequently Asked Questions

When can I get the quotations?

How does your factory do the quality control?

Why choose Vtech's UV LED curing machine?

How to cooperate with you and what is the cooperation process?

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

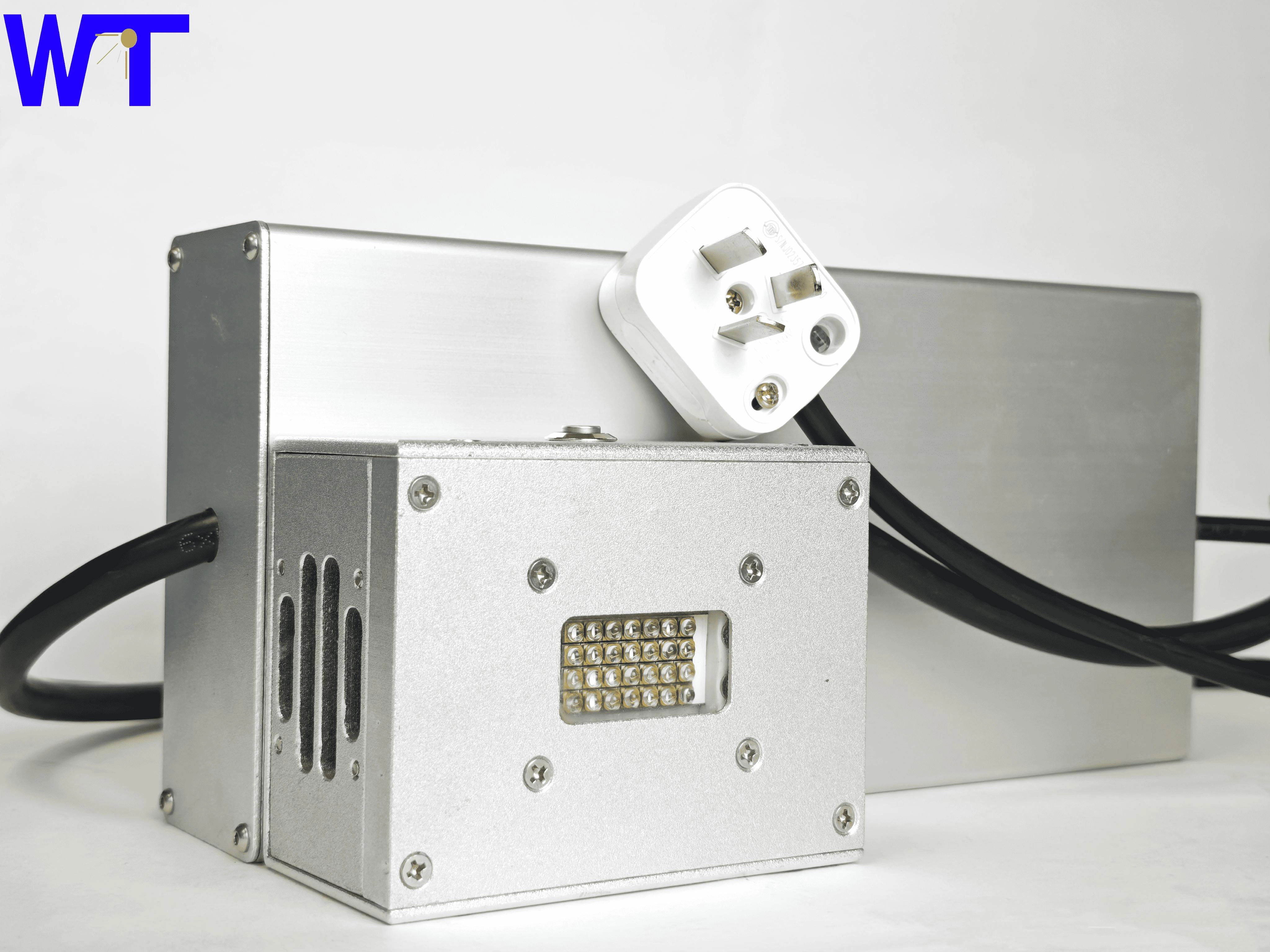

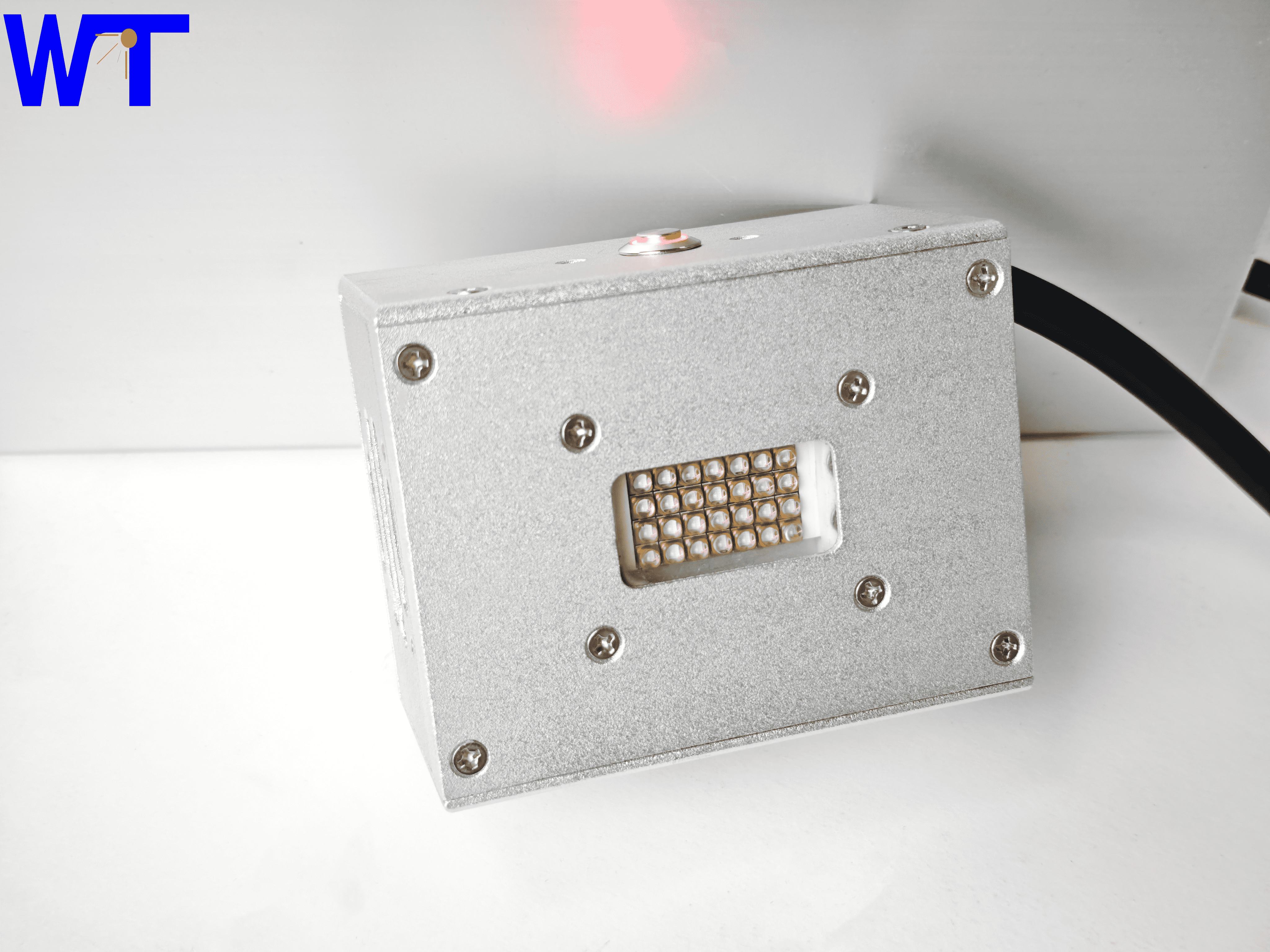

Handheld small LED UV drying equipment

The biggest advantage of handheld small LED UV devices is their simple operation, low power consumption, low temperature, and absolute safety design, which can prevent injury caused by accidental contact.

Attention: Wear sunglasses during use to avoid eye irritation from UV light

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang