WT Bobst Press UV Curing System

Product Overview

The WT Bobst Press UV Curing System is a professional UV and LED curing solution designed specifically for Bobst machines. Built by Vtech Co., Ltd, a company established in 2006 with multiple industry patents, this system brings stable, fast, and reliable curing to offset, gravure, and flexo presses as well as coatings and silk screen applications.

Key Benefits

Stable Temperature Control

Our water-cooled design keeps lamp temperature consistent. This prevents overheating and ensures uniform curing across the web. Stable temperatures increase uptime and reduce quality issues.

Energy-Efficient LED Option

Choose the LED UV variant for lower power consumption and longer lamp life. LED technology reduces energy costs and minimizes heat output, making it ideal for sensitive substrates.

Reliable Performance

With robust components and proven patents, the WT system delivers repeatable curing results. Users get consistent gloss, adhesion, and dry speed that meet demanding production schedules.

Easy Integration and Use

The system is designed for straightforward installation on Bobst press models. Controls are simple and intuitive, so operators can set up and run production quickly. Maintenance is easy with accessible parts and clear service procedures.

Why Choose Vtech WT Systems

Vtech has focused on UV and LED curing since 2006, developing systems for many printing methods. Our experience means reliable products and responsive support. We offer technical guidance, spare parts, and service to keep your press running smoothly.

Applications

Ideal for offset, gravure, and flexo presses, as well as coating lines and silk screen printing. The WT Bobst Press UV Curing System adapts to a variety of substrates including paper, film, and board.

Summary

The WT Bobst Press UV Curing System combines patented design, dependable water-cooled performance, and an energy-saving LED option. It offers easy installation, low maintenance, and consistent curing quality—backed by Vtech’s industry experience and support.

Product Image

Our Advantages

Can be designed and customized development, a variety of optical wavelength optional.

1. The conveyor speed can adjustment according to the products drying condition;

LEDs do not produce ozone gas.

According offset parameters made. Required to provide matching offset spout length, the whole width, height and tilt angle of UV machine.

FAQ

What's the whole UV LED curing system including?

What's the Peak Irradiance do I need?

Why and how do I replace a UV led?

Are you a trader or manufacturer?

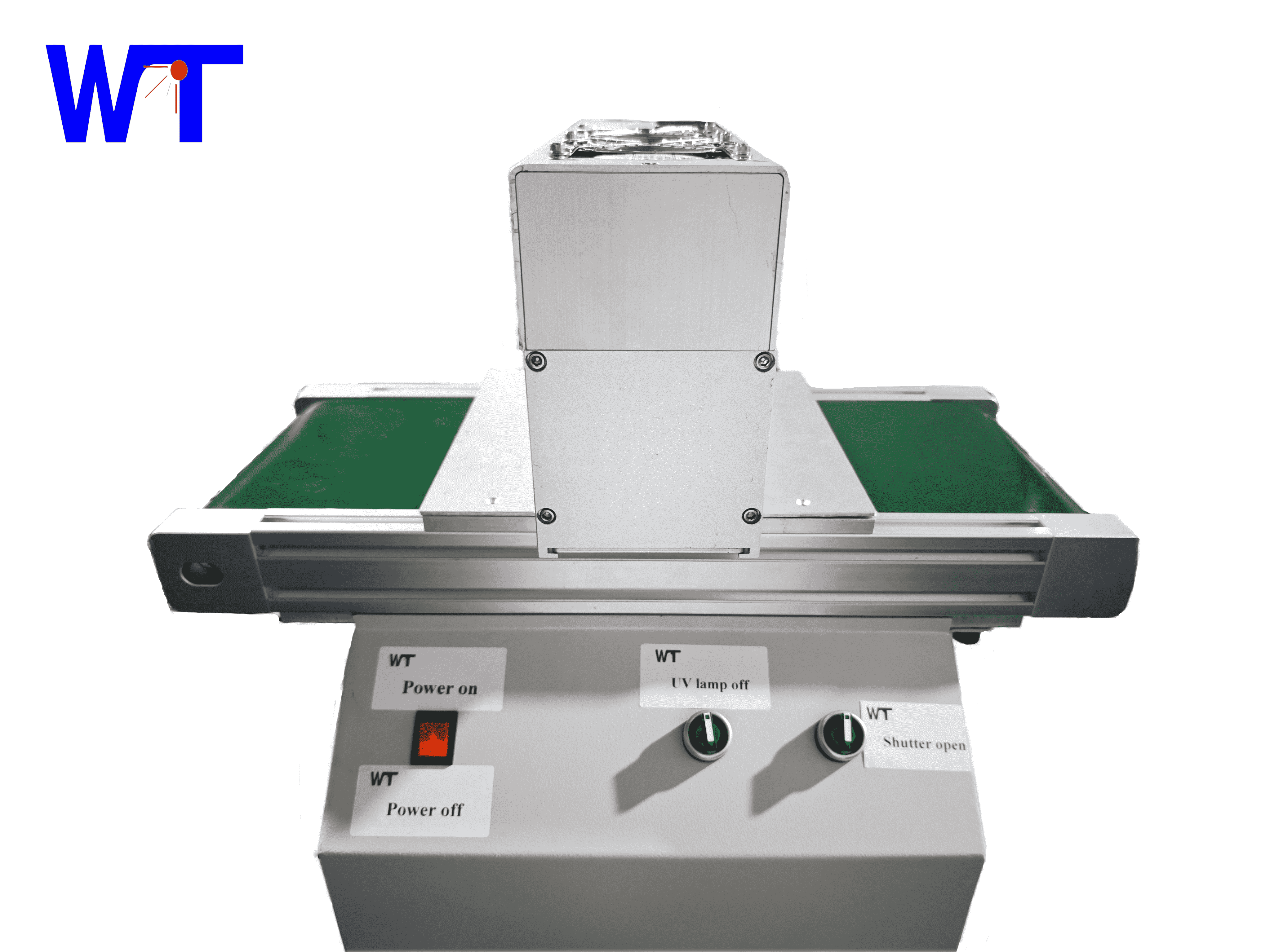

Small UV drying machine

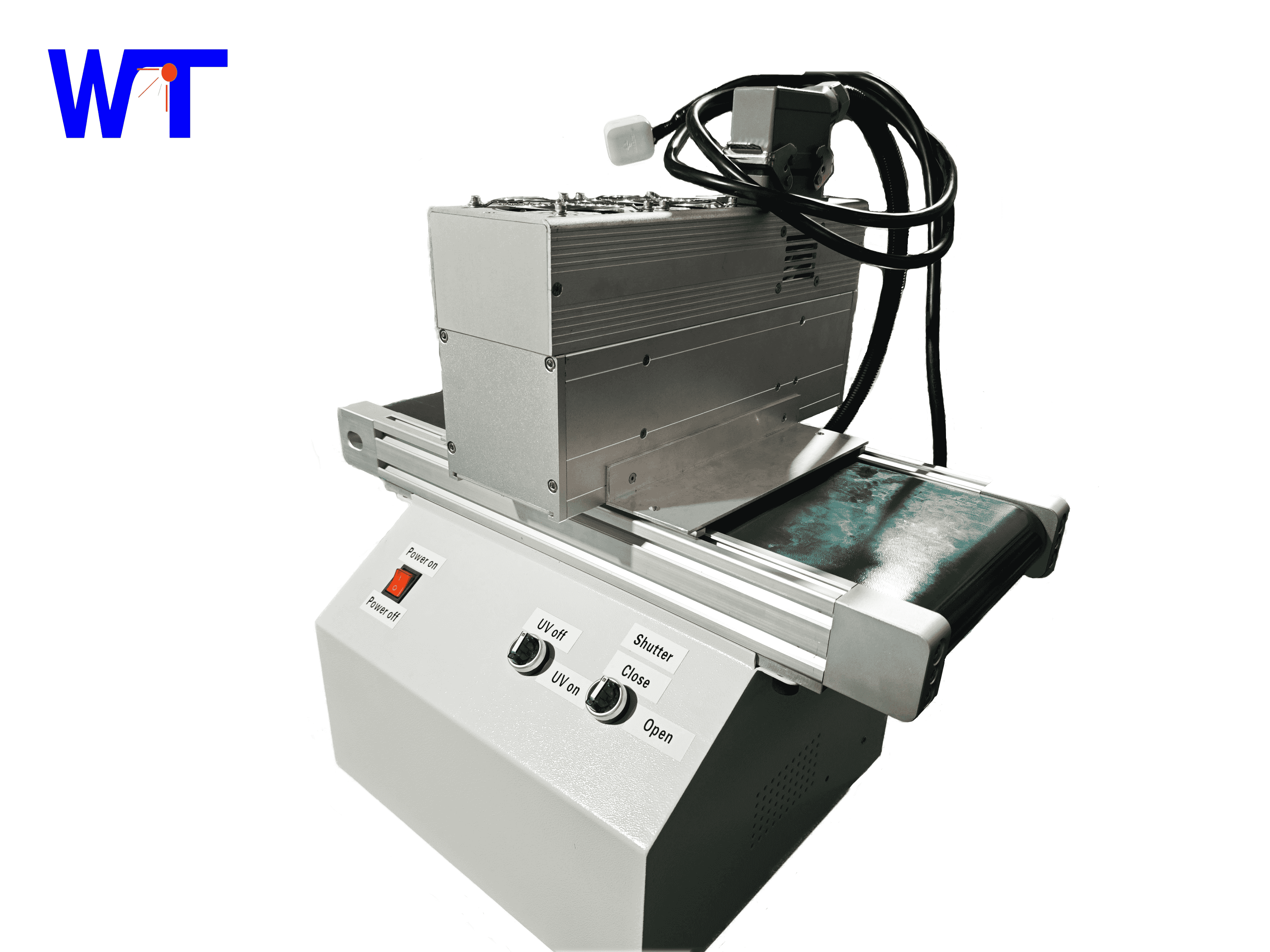

Customized conveyor belt type UV LED curing equipment

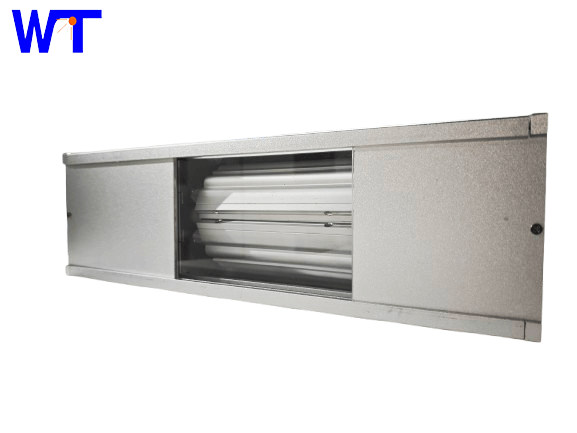

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang