WT Bobst LED UV Curing System: Revolutionize Your Print Production

Elevate Your Printing with WT Bobst LED UV Curing

Experience a revolution in print quality and efficiency with the WT Bobst LED UV Curing System. Engineered by Vtech Co., Ltd., a leader in UV curing technology since 2006, this advanced system is meticulously designed to integrate seamlessly with your Bobst presses, delivering superior curing performance that sets new industry standards. Say goodbye to lengthy drying times and high energy costs, and usher in an era of crisp, vibrant prints with enhanced durability.

Unmatched Performance for Bobst Presses

Our WT LED UV curing solution is specifically optimized to complement the precision and speed of Bobst equipment. It ensures instant, complete curing for a wide range of substrates, enhancing scratch resistance and achieving exceptional print finish. This synergy between our cutting-edge curing technology and your Bobst press means faster throughput, reduced waste, and a significant boost in overall productivity. Trust WT to unlock the full potential of your printing operations.

The Power of LED UV Technology

Harness the myriad benefits of LED UV. The WT system offers remarkable energy efficiency, consuming significantly less power than traditional UV lamps. Its instant on/off capability eliminates warm-up times, further conserving energy and extending lamp life. With no ozone emissions and a greatly reduced heat footprint, our LED UV system creates a safer, more sustainable working environment, aligning with modern ecological demands.

Why Choose WT (Vtech) for Your Curing Needs?

Vtech Co., Ltd., the innovator behind the WT brand, has been at the forefront of UV and LED curing system development for over 15 years. Our deep expertise and numerous industry patents reflect our commitment to excellence and continuous innovation.

A Legacy of Innovation and Expertise

Established in 2006, Vtech specializes in both water-cooled and LED UV curing systems, catering to diverse applications including offset press, gravure press, flexo press, coatings, and silk screen print. Our extensive research and development have resulted in robust, reliable systems that meet the stringent demands of modern industrial printing. When you choose WT, you're choosing a partner with a proven track record and unparalleled technical know-how.

Reliability You Can Trust

We understand that consistent performance is critical to your business. The WT Bobst LED UV Curing System is built for durability and long-term, trouble-free operation. Our commitment to quality ensures stable curing results, minimizing downtime and maximizing your production uptime. Partner with Vtech for reliable service and efficient production that brings peace of mind, knowing your investment is secure.

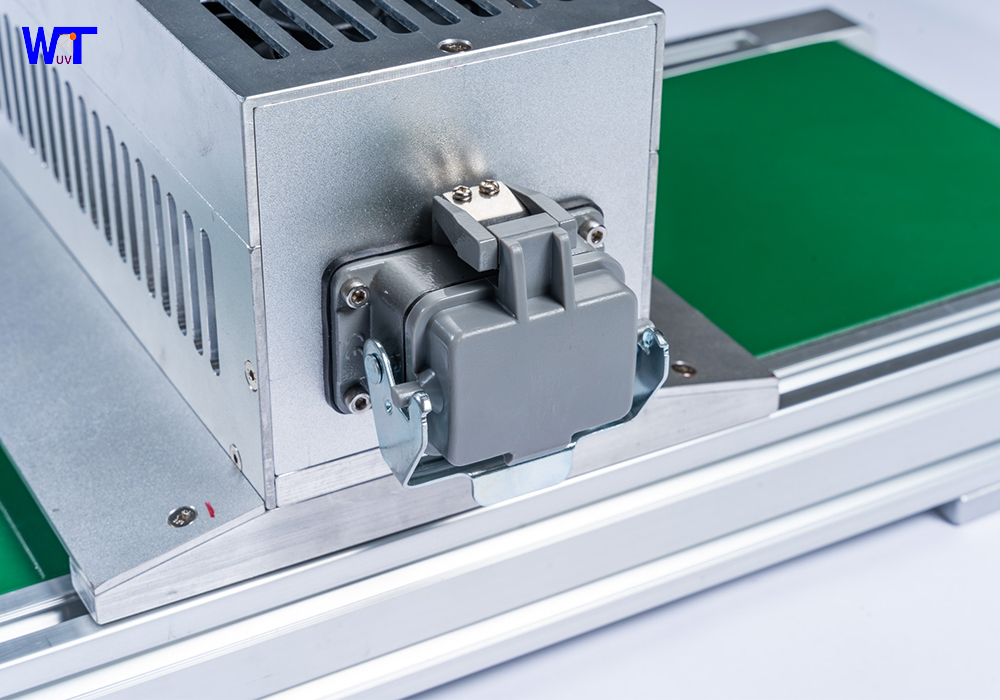

Picture Show

Our Advantages

We are the source factory with professional R&D team and skilled workers.

We have over 17 years experience in UV curing industry.

The operation interface is simple, the sound and light alarm corresponds to the light source module, and the fault can be quickly determined.

The light source head adopts a modular design.

Q&A

How does your factory do the quality control?

Are you a trader or manufacturer?

When can I get the quotations?

Why and how do I replace a UV led?

If you have any other questions, please write email to us or call us , we will reply you ASAP.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang