WT Bobst Flexo Mercury UV Curing System

Overview

The WT Bobst Flexo Mercury UV Curing System is a practical, high-efficiency solution specially designed for Bobst flexographic presses. Built by Vtech Co., Ltd — founded in 2006 and a leader in water-cooled and LED UV systems — this mercury UV unit offers stable curing performance, easy installation, and dependable service backed by industry patents and years of experience.

Why choose WT Mercury UV for Bobst Flexo?

Reliable and consistent curing

The mercury lamp provides strong, even UV output to cure inks and coatings quickly and uniformly. That translates to sharper print quality, fewer rejects, and faster line speeds without complex adjustments.

Designed for production efficiency

WT’s water-cooled design keeps lamp temperature stable for long runs, reducing lamp cycles and downtime. Fast warm-up and consistent output mean shorter make-readies and higher throughput on every shift.

Easy integration and maintenance

The unit is compatible with Bobst flexo presses and engineered for straightforward installation. User-friendly access panels and modular parts simplify routine maintenance so your team spends less time servicing equipment and more time running jobs.

Value and support from Vtech

Vtech Co., Ltd has decades of experience developing UV solutions for offset, gravure, flexo, coatings, and screen print. With multiple industry patents and a focus on reliable service, Vtech provides technical guidance, spare parts, and responsive after-sales support — helping you maximize uptime and production efficiency.

Practical benefits at a glance

- Faster curing and higher line speeds

- Consistent print quality with fewer defects

- Water-cooled stability for long production runs

- Simple installation and low-maintenance design

- Professional support from an experienced manufacturer

Choose the WT Bobst Flexo Mercury UV Curing System to improve your press performance, reduce waste, and keep production running smoothly with a trusted, industry-proven solution.

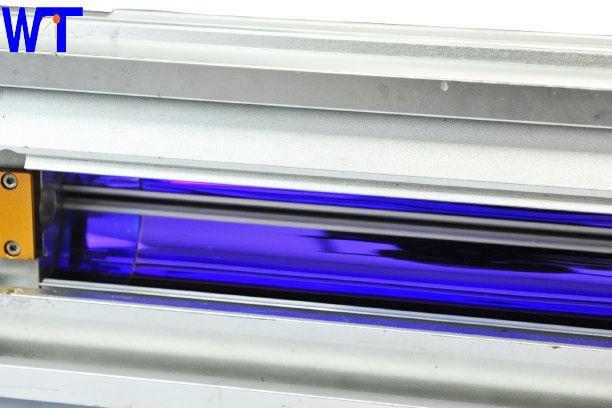

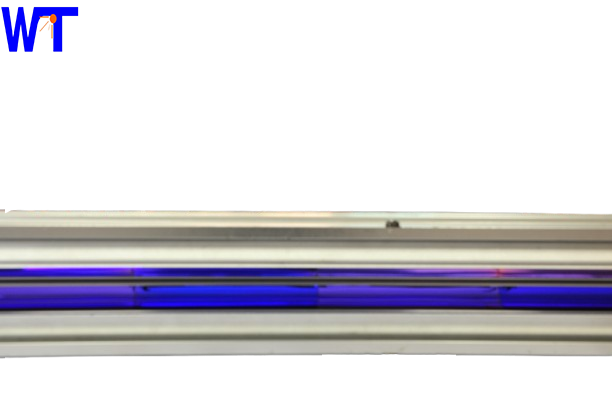

Product Images

Advantages

24 Hours Service Hotline: All our team of service are fully conversant with our extensive range of products and can quickly and expertly talk you through any question you may ask. Vtech is committed to provide a 24 hours customer service/breakdown hotline in local office.

With line disconnection alarm and LED dead point detection alarm function.

LEDs do not produce ozone gas.

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

Question you may concern

When can I get the quotations?

What's the Peak Irradiance do I need?

How about the after service?

Are you a trader or manufacturer?

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Air-cooled LED UV for label machine

This air-cooled LED UV curing system is specially designed for label printers. With efficient air-cooling and LED light source technology, it rapidly cures label printing ink, improving production efficiency and reducing energy consumption. It is compatible with various label printing equipment, helping enterprises achieve high-quality and low-cost label production.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang