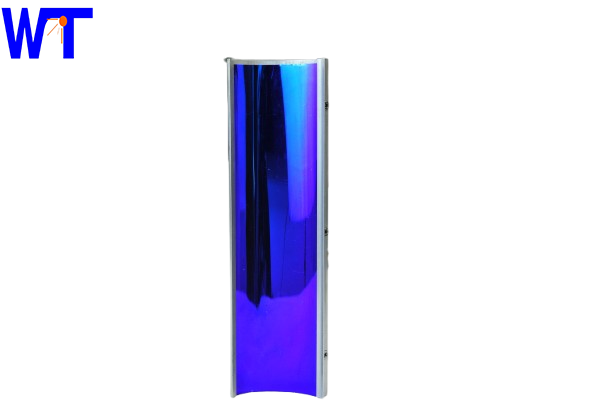

WT Arc UV Curing System for Bobst Flexography Printing Machines

Product Overview

The WT arc UV curing system is designed specifically for Bobst flexography printing machines. Developed by Vtech Co., Ltd., a company established in 2006 with extensive experience in water-cooled and LED UV curing technologies, this system offers dependable performance, smooth integration and user-friendly operation. It is ideal for printers who need consistent, fast curing without compromising quality.

Key Features

- Water-cooled arc lamp design for stable temperature control and long-term operation.

- Optimized for Bobst flexo presses, ensuring easy installation and alignment.

- Adjustable power settings for different inks and substrates.

- Uniform curing across the web to reduce defects and reprints.

- Robust safety features including interlocks and shielding for operator protection.

- Simple maintenance with easy-access lamp and reflector replacement.

Benefits

This system delivers fast drying times and consistent adhesion, helping printers increase throughput and reduce waste. The water-cooled design keeps the curing area stable, protecting sensitive materials while maintaining high output. Backed by Vtech’s patented technologies and experienced support team, WT systems provide reliability you can trust.

Technical Highlights

- Compatibility: Custom mounting options for Bobst flexographic presses.

- Cooling: Closed-loop water cooling for temperature stability.

- Control: Easy-to-use power and exposure controls for precise curing.

- Service: Accessible components for fast on-site servicing.

Why Choose WT Arc UV System?

Vtech’s WT arc UV curing system combines practical engineering and proven field experience. With multiple patents and decades of development in UV solutions for offset, gravure, flexo, coatings and screen printing, Vtech offers reliable products and responsive service. Choose WT for consistent print quality, reduced downtime, and a partner who understands production needs.

For more information, custom integration guidance or service support, contact Vtech Co., Ltd. Our team is ready to help you optimize curing performance on your Bobst flexo press.

Product Image

Advantages

LEDs do not produce ozone gas.

More environmentally friendly and safer. UV LED has no infrared radiation, no harmful gas, and meets ROHS standards.

The light source head adopts a modular design.

1. The conveyor speed can adjustment according to the products drying condition;

FAQ

Can we visit the factory?

Where is your factory located?

How long will take for mass production?

How does your factory do the quality control?

About other questions pls contact me directily.

Water-cooled UV Curing Equipment

Guangzhou Weitai has a variety of UV curing systems with different cooling methods to meet a wide range of UV process applications.

Water-cooled LED curing equipment

Offset LED pre-press testing machine

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang