what is the difference between uv and led curing lamps | WT Guide

UV vs. LED Curing Lamps: What's the Difference?

Choosing between UV and LED curing lamps can be tricky. This article clarifies the key differences between UV and LED curing technologies, helping you select the optimal solution for your specific application. We'll explore their performance, cost, and environmental impact to guide your decision-making process.

Understanding UV Curing

UV (ultraviolet) curing lamps utilize mercury vapor lamps to emit UV light. This light initiates a photochemical reaction in specialized UV-curable inks, coatings, and adhesives, causing them to rapidly polymerize and harden.

Understanding LED Curing

LED (light-emitting diode) curing lamps employ semiconductor diodes to generate UV light. These diodes produce a more targeted and efficient spectrum of UV light compared to traditional UV lamps.

Key Differences Between UV and LED Curing Lamps

| Feature | UV Curing | LED Curing |

|--|-||

| Light Source | Mercury vapor lamp | Semiconductor diodes |

| Energy Efficiency | Lower | Higher |

| Heat Generation | Significantly higher | Much lower |

| Lamp Life | Shorter (requires frequent replacements) | Longer (reducing replacement costs) |

| Curing Speed | Can be faster for specific applications | Generally comparable, often faster for some |

| Wavelength Control | Less precise | More precise, specific wavelengths selectable |

| Mercury Content | Contains mercury (environmental concern) | Mercury-free (environmentally friendly) |

| Initial Cost | Typically lower upfront investment | Typically higher initial investment |

| Operating Costs | Higher long-term due to lamp replacement | Lower long-term due to longer lamp life |

Choosing the Right Technology

The best choice depends on your priorities. UV curing remains cost-effective for some applications, particularly those with high throughput requirements where initial cost is a primary factor. However, LED curing offers significant long-term cost savings due to extended lamp life and reduced energy consumption, making it a more sustainable option. The higher precision wavelength control offered by LED technology allows for more tailored curing processes, enhancing efficiency and performance. Consider the overall cost of ownership—including lamp replacements, energy usage, and potential environmental impacts—when making your decision.

Google Page Title: UV vs LED Curing Lamps: A Comparison Guide | WT

2025 Jakarta Printing Exhibition in Indonesia(All Print Indonesia)

Vietnam Print Pack 2025 Concludes Successfully: Innovative Water-Cooled UV Systems Lead New Trends in Green Printing

Post exhibition report: Water cooled UV/LED system shines at RoSupack 2025, promoting green and sustainable printing

How does UV technology make your product stand out?

The 11th Beijing International Printing Technology Exhibition Concluded Successfully, Vtech.Co.,Ltd.Guangzhou Achieved Fruitful Results

Vtech water-cooled UV/LED system helps Roland 300 printing machine upgrade efficiency again!

You may also like

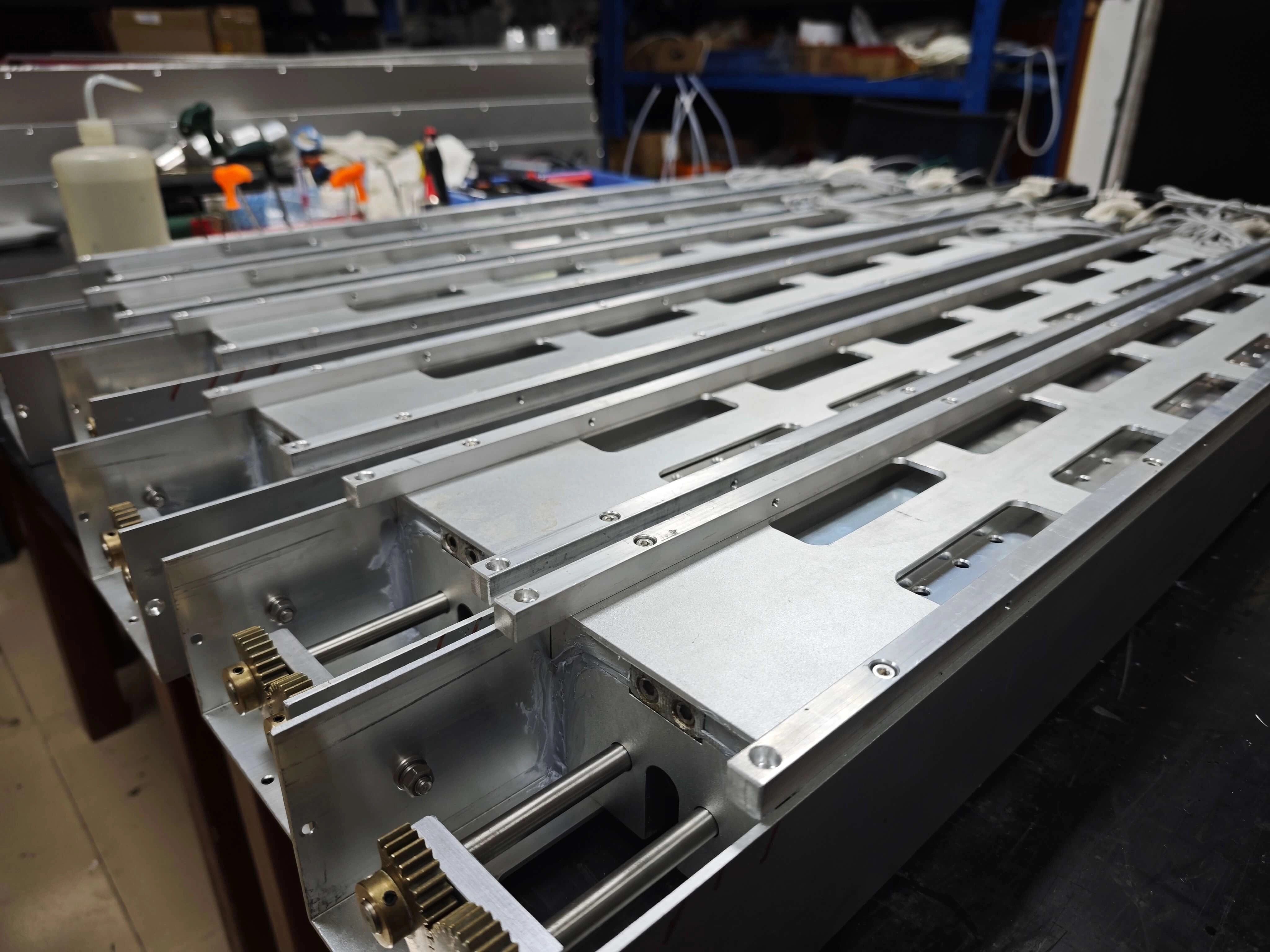

Water cooled UV shutter lampshade

The Water-Cooled UV Shutter lampshade is a high-performance solution designed for modern high-speed printing presses, addressing critical challenges in UV ink and coating curing. By integrating advanced water-cooling technology and a precision shutter mechanism, it ensures stable UV exposure control, minimizes heat generation, and maximizes production uptime for industries requiring rapid, reliable curing processes.

Automatic UV Spot Machine

Automatic control

- The motor USES frequency conversion speed regulation, safe and reliable.

- The whole machine USES PLC programmable control, simple operation, easy maintenance.

- All parts of the cable are connected by fast connector, easy to install.

LED water-cooled lampshade

LED water-cooled lampshade is an innovative curing equipment developed specifically for high-speed printing machines. It combines efficient water-cooled heat dissipation technology with high-energy LED light sources, aiming to solve the problems of light source overheating, rapid light decay, and short lifespan caused by long-term high-speed operation of traditional printing equipment. Its core design uses a circulating water cooling system for precise temperature control, ensuring stable output of the light source while meeting the stringent requirements of printing technology for light uniformity, color temperature consistency, and energy conservation and environmental protection. It is an ideal choice for improving printing quality and production efficiency.

UV Dichroic

Dichroic imported from Germany, high-precision color separation, precise control of CMYK dot expansion, adapted to the fast curing characteristics of UV ink, reduces color difference, and is durable

Get in touch with us

Copyright © 2023 WTJD.NET All Rights Reserved. | Privacy Policy • Terms and Conditions | Sitemap

Scan QR Code

Scan QR Code

vape.king05

WT UV Led Ouyang